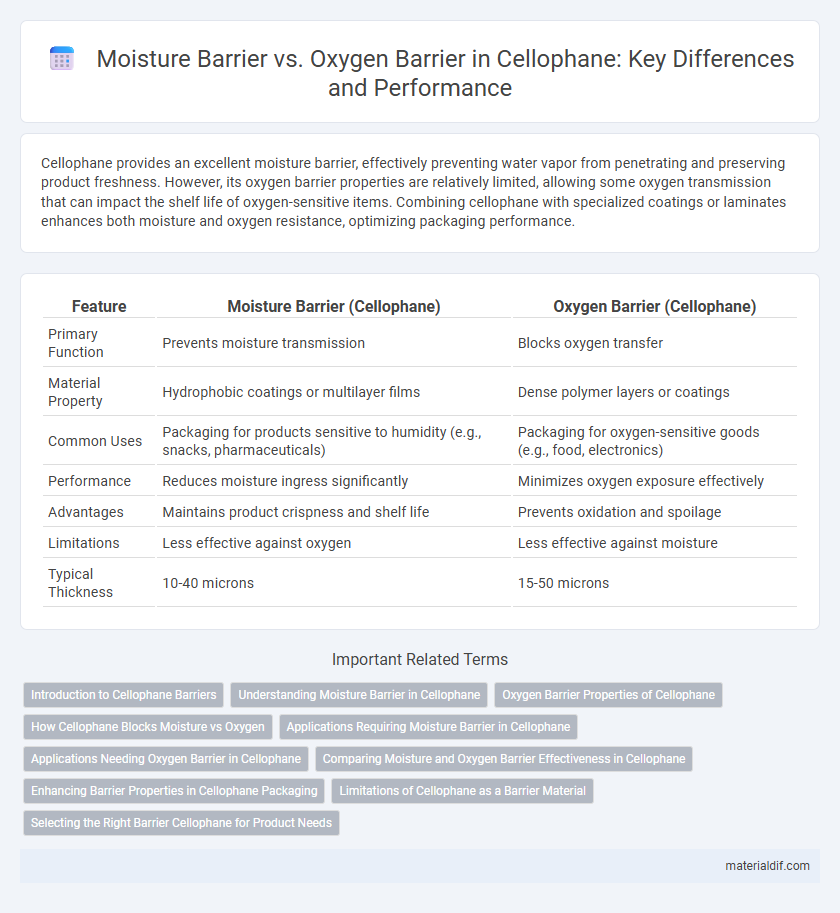

Cellophane provides an excellent moisture barrier, effectively preventing water vapor from penetrating and preserving product freshness. However, its oxygen barrier properties are relatively limited, allowing some oxygen transmission that can impact the shelf life of oxygen-sensitive items. Combining cellophane with specialized coatings or laminates enhances both moisture and oxygen resistance, optimizing packaging performance.

Table of Comparison

| Feature | Moisture Barrier (Cellophane) | Oxygen Barrier (Cellophane) |

|---|---|---|

| Primary Function | Prevents moisture transmission | Blocks oxygen transfer |

| Material Property | Hydrophobic coatings or multilayer films | Dense polymer layers or coatings |

| Common Uses | Packaging for products sensitive to humidity (e.g., snacks, pharmaceuticals) | Packaging for oxygen-sensitive goods (e.g., food, electronics) |

| Performance | Reduces moisture ingress significantly | Minimizes oxygen exposure effectively |

| Advantages | Maintains product crispness and shelf life | Prevents oxidation and spoilage |

| Limitations | Less effective against oxygen | Less effective against moisture |

| Typical Thickness | 10-40 microns | 15-50 microns |

Introduction to Cellophane Barriers

Cellophane provides essential moisture and oxygen barriers critical for packaging applications, ensuring product preservation and shelf-life extension. Its moisture barrier properties prevent water vapor transmission, protecting products from humidity and maintaining freshness. The oxygen barrier limits oxygen ingress, reducing oxidation and spoilage, with both barriers tailored through chemical treatments and coatings to enhance specific protection needs.

Understanding Moisture Barrier in Cellophane

Moisture barrier in cellophane is critical for preserving product freshness by preventing water vapor transmission, which helps maintain texture and shelf life. This barrier is achieved through chemical treatments or coatings that reduce the inherent hydrophilic nature of cellophane, enhancing its resistance to moisture absorption. Effective moisture barrier cellophane is essential in packaging applications for food, pharmaceuticals, and other moisture-sensitive products.

Oxygen Barrier Properties of Cellophane

Cellophane exhibits excellent oxygen barrier properties, making it a preferred packaging material for preserving food freshness and extending shelf life by preventing oxygen ingress. Its dense polymer structure significantly reduces oxygen permeability compared to many other films, thereby limiting oxidation and spoilage. This oxygen barrier capability is crucial in applications requiring protection against aerobic microbial growth and oxidation-sensitive products.

How Cellophane Blocks Moisture vs Oxygen

Cellophane exhibits superior moisture barrier properties due to its dense, hydrophilic cellulose structure that effectively restricts water vapor transmission, making it ideal for packaging items sensitive to moisture. However, its oxygen barrier performance is comparatively moderate, as oxygen molecules can permeate through the micro-pores in the cellulose matrix more readily than water vapor. Enhancements like the application of nitrocellulose coatings or laminations improve oxygen barrier properties, while uncoated cellophane primarily excels at blocking moisture.

Applications Requiring Moisture Barrier in Cellophane

Cellophane provides an effective moisture barrier, making it ideal for packaging products like fresh produce, confectionery, and pharmaceuticals where moisture control is critical to maintaining quality and shelf life. Its natural cellulose composition allows for breathability while protecting contents from moisture ingress, preventing spoilage and clumping in hygroscopic goods. Although cellophane has limited oxygen barrier properties compared to synthetic films, its superior moisture resistance suits applications requiring protection against humidity rather than oxygen exposure.

Applications Needing Oxygen Barrier in Cellophane

Cellophane's oxygen barrier properties are crucial for packaging applications requiring protection against oxidation, such as fresh produce, pharmaceuticals, and snack foods, where oxygen exposure can degrade product quality and shelf life. Its ability to prevent oxygen permeation helps maintain freshness, prevent spoilage, and preserve flavors in oxygen-sensitive goods. Industries focusing on food preservation and medical packaging prefer oxygen-barrier cellophane to ensure extended storage times and product integrity.

Comparing Moisture and Oxygen Barrier Effectiveness in Cellophane

Cellophane exhibits strong oxygen barrier properties, making it highly effective for preserving food freshness by preventing oxidative spoilage. However, its moisture barrier is comparatively weaker, allowing water vapor transmission that can affect products sensitive to humidity. Advances in coating technologies have enhanced cellophane's moisture resistance, yet oxygen barrier effectiveness remains its primary strength in packaging applications.

Enhancing Barrier Properties in Cellophane Packaging

Cellophane's moisture barrier properties primarily limit water vapor transmission, essential for maintaining product freshness and preventing spoilage in high-humidity environments. Oxygen barrier enhancements in cellophane packaging reduce oxygen permeability, thereby extending shelf life and preserving the quality of oxygen-sensitive goods. Advanced coatings and multilayer lamination techniques are commonly employed to optimize both moisture and oxygen barriers, balancing protection and clarity for effective packaging solutions.

Limitations of Cellophane as a Barrier Material

Cellophane exhibits strong moisture barrier properties due to its dense polymer network but is limited by poor oxygen barrier performance, allowing oxygen transmission that can degrade sensitive products. Its inherent hydrophilic nature causes moisture absorption, compromising barrier efficiency in humid conditions. These limitations restrict cellophane's use in packaging applications requiring stringent protection against oxygen exposure and varying humidity levels.

Selecting the Right Barrier Cellophane for Product Needs

Moisture barrier cellophane excels at protecting products from humidity and water vapor, making it ideal for packaging fresh produce, baked goods, and pharmaceuticals requiring moisture control. Oxygen barrier cellophane effectively limits oxygen exposure, preserving the shelf life and freshness of sensitive items like snacks, confectionery, and medical supplies susceptible to oxidation. Selecting the right barrier cellophane depends on the product's sensitivity to moisture or oxygen, ensuring optimal preservation and maintaining quality during storage and distribution.

Moisture Barrier vs Oxygen Barrier (in Cellophane) Infographic

materialdif.com

materialdif.com