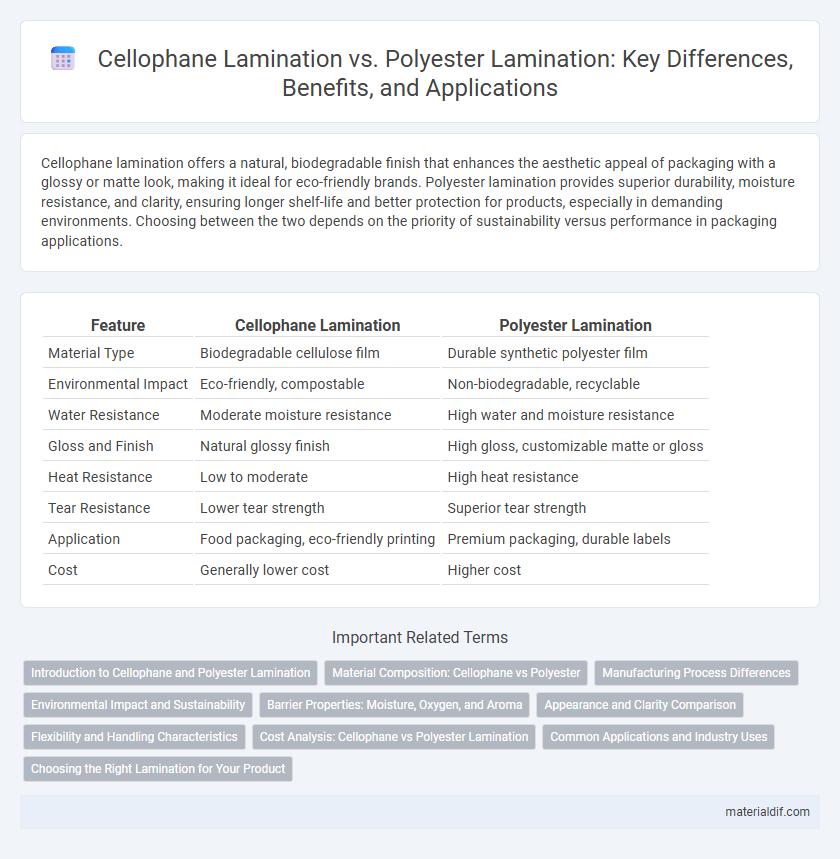

Cellophane lamination offers a natural, biodegradable finish that enhances the aesthetic appeal of packaging with a glossy or matte look, making it ideal for eco-friendly brands. Polyester lamination provides superior durability, moisture resistance, and clarity, ensuring longer shelf-life and better protection for products, especially in demanding environments. Choosing between the two depends on the priority of sustainability versus performance in packaging applications.

Table of Comparison

| Feature | Cellophane Lamination | Polyester Lamination |

|---|---|---|

| Material Type | Biodegradable cellulose film | Durable synthetic polyester film |

| Environmental Impact | Eco-friendly, compostable | Non-biodegradable, recyclable |

| Water Resistance | Moderate moisture resistance | High water and moisture resistance |

| Gloss and Finish | Natural glossy finish | High gloss, customizable matte or gloss |

| Heat Resistance | Low to moderate | High heat resistance |

| Tear Resistance | Lower tear strength | Superior tear strength |

| Application | Food packaging, eco-friendly printing | Premium packaging, durable labels |

| Cost | Generally lower cost | Higher cost |

Introduction to Cellophane and Polyester Lamination

Cellophane lamination provides a biodegradable, moisture-resistant coating made from regenerated cellulose, offering eco-friendly packaging with a natural glossy finish. Polyester lamination, using biaxially oriented polyethylene terephthalate (PET), delivers superior durability, chemical resistance, and clarity, ideal for high-strength packaging applications. Both lamination types enhance product protection and aesthetics but differ significantly in environmental impact and mechanical properties.

Material Composition: Cellophane vs Polyester

Cellophane lamination consists of regenerated cellulose derived from wood pulp, providing a biodegradable and breathable film that enhances product visibility and offers moderate moisture resistance. Polyester lamination, made from polyethylene terephthalate (PET), delivers superior durability, chemical resistance, and moisture barrier properties, making it ideal for long-term protection and strength. The key material difference lies in cellophane's eco-friendly nature versus polyester's robustness and enhanced performance in harsh conditions.

Manufacturing Process Differences

Cellophane lamination involves the use of regenerated cellulose film derived from wood pulp through a viscose process, offering biodegradability and a natural appearance. Polyester lamination employs polyethylene terephthalate (PET) films created via polymerization of terephthalic acid and ethylene glycol, providing superior strength and moisture resistance. Manufacturing differences include solvent-based dispersion coating for cellophane and extrusion coating or thermal bonding for polyester, affecting adhesion properties and environmental impact.

Environmental Impact and Sustainability

Cellophane lamination offers a biodegradable and compostable alternative to polyester lamination, significantly reducing environmental impact by minimizing plastic waste in landfills and oceans. Unlike polyester, which is derived from non-renewable petroleum resources and contributes to microplastic pollution, cellophane is made from regenerated cellulose sourced from sustainably managed forests. This sustainability advantage makes cellophane lamination ideal for eco-conscious packaging applications seeking to lower carbon footprints and enhance recyclability.

Barrier Properties: Moisture, Oxygen, and Aroma

Cellophane lamination offers excellent moisture barrier properties due to its dense cellulose structure, effectively preventing water vapor transmission. Polyester lamination provides superior oxygen barrier performance, making it ideal for packaging items sensitive to oxidation, such as food products. In terms of aroma retention, polyester lamination excels by minimizing scent migration, whereas cellophane lamination has moderate aroma barrier capabilities.

Appearance and Clarity Comparison

Cellophane lamination offers a natural, glossy finish with high clarity that enhances the visual appeal of printed materials by providing vibrant color reproduction and a smooth surface. In contrast, polyester lamination delivers superior durability and a more rigid structure but often results in a slightly less transparent and glossier appearance compared to cellophane. The choice between cellophane and polyester lamination significantly impacts the aesthetic quality, with cellophane favored for its clarity and natural luster in packaging and presentation.

Flexibility and Handling Characteristics

Cellophane lamination offers superior flexibility and softness, making it ideal for packaging that requires easy folding and handling. Polyester lamination, while providing excellent strength and durability, tends to be stiffer and less pliable than cellophane. The enhanced flexibility of cellophane improves tear resistance and facilitates seamless application on curved or irregular surfaces.

Cost Analysis: Cellophane vs Polyester Lamination

Cellophane lamination typically offers a lower cost compared to polyester lamination due to its biodegradable nature and simpler manufacturing process. Polyester lamination, while more expensive, provides superior durability, moisture resistance, and clarity, which may justify the higher investment for premium packaging. Choosing between cellophane and polyester lamination depends on balancing budget constraints with desired product performance and environmental considerations.

Common Applications and Industry Uses

Cellophane lamination is widely used in food packaging for products like confectionery, fresh produce, and bakery items due to its biodegradability and moisture barrier properties. Polyester lamination is common in pharmaceutical packaging, electronic goods, and luxury product wrapping, offering superior durability, clarity, and resistance to chemicals and heat. Both laminations serve the packaging industry but are selected based on specific application needs such as environmental sustainability or enhanced protection.

Choosing the Right Lamination for Your Product

Cellophane lamination provides a biodegradable, glossy finish that enhances product visual appeal while maintaining eco-friendliness, ideal for packaging requiring breathability. Polyester lamination offers superior durability, moisture resistance, and a high-gloss or matte finish, making it suitable for products demanding longer shelf life and protection against external elements. Choosing the right lamination depends on product sensitivity to moisture, environmental impact preferences, and desired aesthetic qualities.

Cellophane Lamination vs Polyester Lamination Infographic

materialdif.com

materialdif.com