Cellophane sheets provide excellent transparency and a biodegradable alternative to synthetic films, making them ideal for eco-friendly packaging, while LDPE sheets offer superior flexibility, moisture resistance, and durability suitable for heavy-duty applications. The choice between cellophane and LDPE sheets hinges on the need for environmental sustainability versus the demand for robust physical protection. Cellophane's natural cellulose composition contrasts with LDPE's petroleum-based polymer, influencing their respective performance in various packaging and wrapping uses.

Table of Comparison

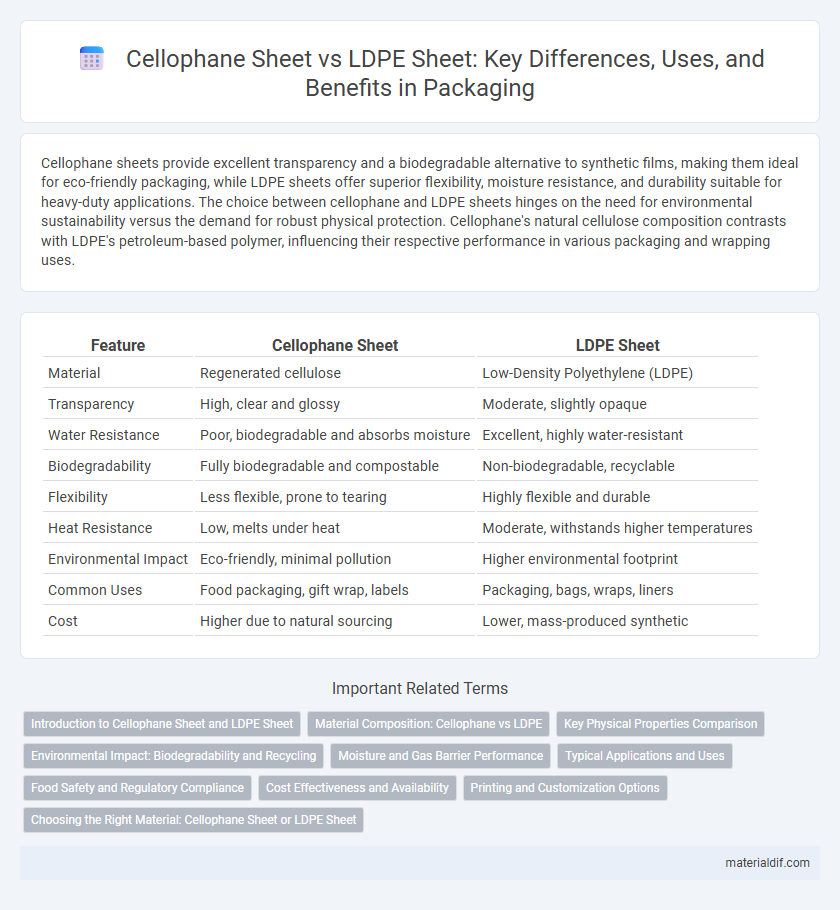

| Feature | Cellophane Sheet | LDPE Sheet |

|---|---|---|

| Material | Regenerated cellulose | Low-Density Polyethylene (LDPE) |

| Transparency | High, clear and glossy | Moderate, slightly opaque |

| Water Resistance | Poor, biodegradable and absorbs moisture | Excellent, highly water-resistant |

| Biodegradability | Fully biodegradable and compostable | Non-biodegradable, recyclable |

| Flexibility | Less flexible, prone to tearing | Highly flexible and durable |

| Heat Resistance | Low, melts under heat | Moderate, withstands higher temperatures |

| Environmental Impact | Eco-friendly, minimal pollution | Higher environmental footprint |

| Common Uses | Food packaging, gift wrap, labels | Packaging, bags, wraps, liners |

| Cost | Higher due to natural sourcing | Lower, mass-produced synthetic |

Introduction to Cellophane Sheet and LDPE Sheet

Cellophane sheets are biodegradable films made from cellulose, known for their clarity, moisture resistance, and eco-friendly properties. LDPE sheets, or low-density polyethylene sheets, are synthetic plastic films characterized by flexibility, durability, and water resistance, widely used in packaging and industrial applications. Comparing both, cellophane offers natural compostability while LDPE provides enhanced strength and chemical resistance.

Material Composition: Cellophane vs LDPE

Cellophane sheets are made from regenerated cellulose derived from wood pulp or cotton fibers, offering biodegradability and breathability. LDPE sheets consist of low-density polyethylene, a thermoplastic polymer sourced from petroleum, known for flexibility and moisture resistance. The fundamental difference in material composition influences their environmental impact, permeability, and typical applications in packaging.

Key Physical Properties Comparison

Cellophane sheets exhibit high clarity, excellent moisture vapor permeability, and biodegradability, making them ideal for sustainable packaging. LDPE sheets offer superior flexibility, impact resistance, and moisture barrier properties, suitable for protective wrapping and insulation. The tensile strength of cellophane is lower than LDPE, but cellophane excels in gas permeability, whereas LDPE's chemical resistance is significantly better.

Environmental Impact: Biodegradability and Recycling

Cellophane sheets, derived from cellulose, are biodegradable and compostable, breaking down naturally within weeks under appropriate conditions, significantly reducing environmental impact compared to LDPE sheets. LDPE sheets, made from petroleum-based plastics, are not biodegradable and persist in landfills for centuries, posing long-term ecological threats and complicating recycling efforts due to contamination and limited facilities. Recycling cellophane is less common but more environmentally favorable, while LDPE recycling is widespread yet energy-intensive and often results in downcycled products with reduced value.

Moisture and Gas Barrier Performance

Cellophane sheets exhibit superior moisture and gas barrier properties compared to LDPE sheets, making them ideal for packaging applications requiring breathability and protection against external contaminants. LDPE sheets offer higher flexibility but lower resistance to moisture vapor transmission and oxygen permeability, which can affect product shelf life. When selecting materials for packaging sensitive goods, cellophane's enhanced barrier performance ensures better preservation of freshness and quality.

Typical Applications and Uses

Cellophane sheets are commonly used for food packaging, gift wrap, and floral wrapping due to their excellent moisture barrier, biodegradability, and clear appearance that preserves product visibility. LDPE sheets, favored in industrial and agricultural applications, offer superior flexibility, toughness, and resistance to chemicals and UV exposure, making them ideal for protective covers, liners, and flexible containers. While cellophane excels in eco-friendly, visually appealing packaging, LDPE sheets provide durability and versatility for heavy-duty and long-term uses.

Food Safety and Regulatory Compliance

Cellophane sheets are biodegradable and derived from cellulose, offering excellent moisture and oxygen barrier properties that enhance food safety by reducing contamination risk. LDPE (Low-Density Polyethylene) sheets, while flexible and durable, are petroleum-based and may have limitations in breathability, potentially affecting food freshness. Regulatory compliance for food packaging favors cellophane due to its natural composition and ease of meeting strict FDA and EU food contact standards, whereas LDPE requires careful additive evaluation to ensure safety.

Cost Effectiveness and Availability

Cellophane sheets generally cost more than LDPE sheets due to their natural cellulose composition and eco-friendly properties, making them less economical for large-scale packaging. LDPE sheets offer superior cost effectiveness with widespread availability and lower manufacturing expenses, commonly used across various industries. While cellophane provides biodegradability, LDPE sheets dominate the market because of their affordability and ready supply.

Printing and Customization Options

Cellophane sheets offer superior print clarity and vibrant color reproduction due to their smooth, transparent surface, making them ideal for high-quality packaging and decorative uses. In contrast, LDPE sheets provide more flexibility and durability but have limited print adhesion, often requiring additional coatings for effective customization. Customization options on cellophane include heat-sealing and various print techniques such as flexographic and digital printing, whereas LDPE customization is generally restricted to surface treatments and simpler printing methods.

Choosing the Right Material: Cellophane Sheet or LDPE Sheet

Cellophane sheets, derived from cellulose, offer superior breathability and biodegradability compared to LDPE (Low-Density Polyethylene) sheets, making them ideal for eco-friendly packaging. LDPE sheets provide enhanced moisture resistance and flexibility, which suits applications requiring durability and water barrier properties. Selecting between cellophane and LDPE sheets depends on the priority between environmental impact and functional performance such as moisture retention or permeability.

Cellophane Sheet vs LDPE Sheet Infographic

materialdif.com

materialdif.com