Cellophane windows offer excellent clarity and biodegradability, making them a sustainable choice for eco-friendly packaging, while PET windows provide superior durability and moisture resistance for enhanced product protection. PET windows also maintain their shape better under pressure and temperature variations, making them ideal for heavier or refrigerated items. Choosing between cellophane and PET windows depends on priorities such as environmental impact versus strength and product shelf life.

Table of Comparison

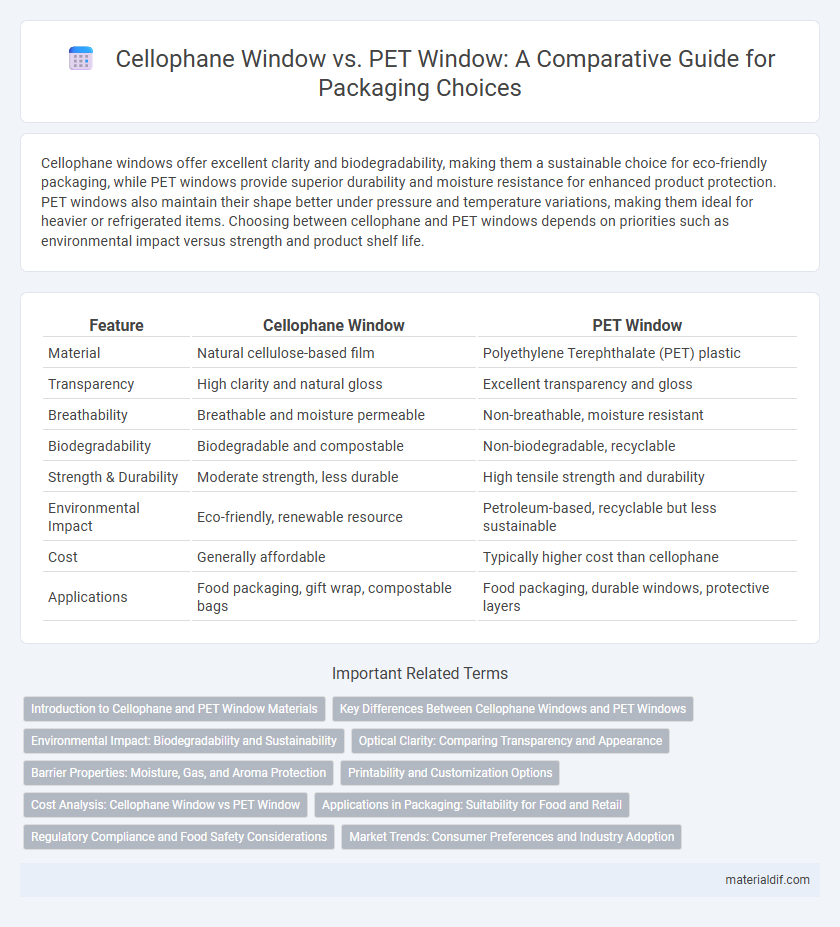

| Feature | Cellophane Window | PET Window |

|---|---|---|

| Material | Natural cellulose-based film | Polyethylene Terephthalate (PET) plastic |

| Transparency | High clarity and natural gloss | Excellent transparency and gloss |

| Breathability | Breathable and moisture permeable | Non-breathable, moisture resistant |

| Biodegradability | Biodegradable and compostable | Non-biodegradable, recyclable |

| Strength & Durability | Moderate strength, less durable | High tensile strength and durability |

| Environmental Impact | Eco-friendly, renewable resource | Petroleum-based, recyclable but less sustainable |

| Cost | Generally affordable | Typically higher cost than cellophane |

| Applications | Food packaging, gift wrap, compostable bags | Food packaging, durable windows, protective layers |

Introduction to Cellophane and PET Window Materials

Cellophane is a thin, transparent film made from regenerated cellulose, widely used for packaging due to its biodegradability and moisture-resistant properties. PET (Polyethylene Terephthalate) windows, derived from polyester, offer superior strength, clarity, and durability compared to cellophane. While cellophane provides excellent aroma and moisture barriers, PET windows are preferred for packaging requiring higher tear resistance and longer shelf life.

Key Differences Between Cellophane Windows and PET Windows

Cellophane windows are biodegradable and made from regenerated cellulose, offering excellent clarity and a natural, eco-friendly appeal, whereas PET windows are derived from polyethylene terephthalate, providing superior strength, durability, and moisture resistance. Cellophane windows tend to have lower heat resistance and are more prone to wrinkling compared to PET windows, which maintain shape and transparency under varying temperature conditions. The environmental impact distinguishes them further, with cellophane decomposing more readily while PET windows often require recycling processes.

Environmental Impact: Biodegradability and Sustainability

Cellophane windows, made from cellulose, are biodegradable and compostable, significantly reducing environmental pollution compared to PET windows, which are derived from petrochemicals and persist in ecosystems for hundreds of years. The production of cellophane involves renewable plant-based materials, promoting sustainability by lowering carbon footprints and relying less on fossil fuels. In contrast, PET windows contribute to plastic waste accumulation and have a larger environmental impact due to their non-biodegradable nature and energy-intensive manufacturing process.

Optical Clarity: Comparing Transparency and Appearance

Cellophane windows offer superior optical clarity with their natural, glossy finish, allowing for high transparency and vivid product visibility. PET windows, while durable and resistant to moisture, often have a slightly less clear appearance that can appear more plastic-like and less vibrant. The choice between cellophane and PET windows depends on whether maximum clarity or durability is prioritized in packaging design.

Barrier Properties: Moisture, Gas, and Aroma Protection

Cellophane windows provide excellent moisture and aroma barrier properties due to their natural cellulose structure, making them ideal for packaging sensitive food products. PET windows offer superior gas barrier protection, especially against oxygen, which enhances shelf life by reducing oxidation. The choice between cellophane and PET windows depends on the specific barrier needs, with cellophane excelling in aroma retention and PET in moisture and oxygen resistance.

Printability and Customization Options

Cellophane windows offer excellent printability with their smooth, natural cellulose surface, allowing vibrant, high-quality color prints and intricate designs. PET windows provide superior customization options due to their compatibility with various printing technologies, including UV and screen printing, enabling sharp graphics and specialized finishes. While cellophane excels in eco-friendly appeal and clarity, PET windows deliver more versatile and durable customization choices for packaging.

Cost Analysis: Cellophane Window vs PET Window

Cellophane windows offer a cost-effective solution with lower material and production expenses compared to PET windows, making them ideal for budget-sensitive packaging applications. PET windows provide superior durability and clarity but come at a higher price point, influencing overall packaging cost. Selecting between cellophane and PET windows depends on cost priorities and required packaging performance.

Applications in Packaging: Suitability for Food and Retail

Cellophane windows offer excellent biodegradability and moisture permeability, making them suitable for packaging fresh produce, bakery items, and other food products requiring breathability. PET windows provide superior strength, clarity, and barrier properties, ideal for retail packaging that demands durability and extended shelf life. Both materials cater to different packaging needs, with cellophane favored for eco-friendly food applications and PET preferred for high-end retail displays.

Regulatory Compliance and Food Safety Considerations

Cellophane windows offer excellent biodegradability and meet strict food safety regulations due to their natural cellulose base, making them ideal for sustainable packaging. PET windows, while highly durable and transparent, require thorough evaluation for compliance with FDA and EU food contact standards to ensure no harmful chemical migration occurs. Both materials must adhere to specific regulatory guidelines to guarantee consumer safety and maintain product integrity in food packaging applications.

Market Trends: Consumer Preferences and Industry Adoption

Consumer preferences increasingly favor PET windows over traditional cellophane windows due to PET's superior durability, clarity, and recyclability, driving significant industry adoption in food packaging. Market trends reveal a growing shift towards sustainable materials, with PET offering better mechanical strength and compatibility with eco-friendly labeling, aligning with regulatory demands. The packaging industry's move toward enhancing product visibility while reducing environmental impact underpins the rising demand for PET window integration.

Cellophane Window vs PET Window Infographic

materialdif.com

materialdif.com