Cellophane tape is made from cellulose and offers excellent biodegradability, making it an eco-friendly choice, while acetate tape is crafted from cellulose acetate, providing superior clarity and resistance to yellowing over time. Cellophane tape typically has a slight natural gloss and is less resistant to moisture compared to acetate tape, which is often preferred for presentations and archival purposes due to its durability. Choosing between cellophane and acetate tape depends on the need for environmental sustainability versus long-lasting clarity and moisture resistance.

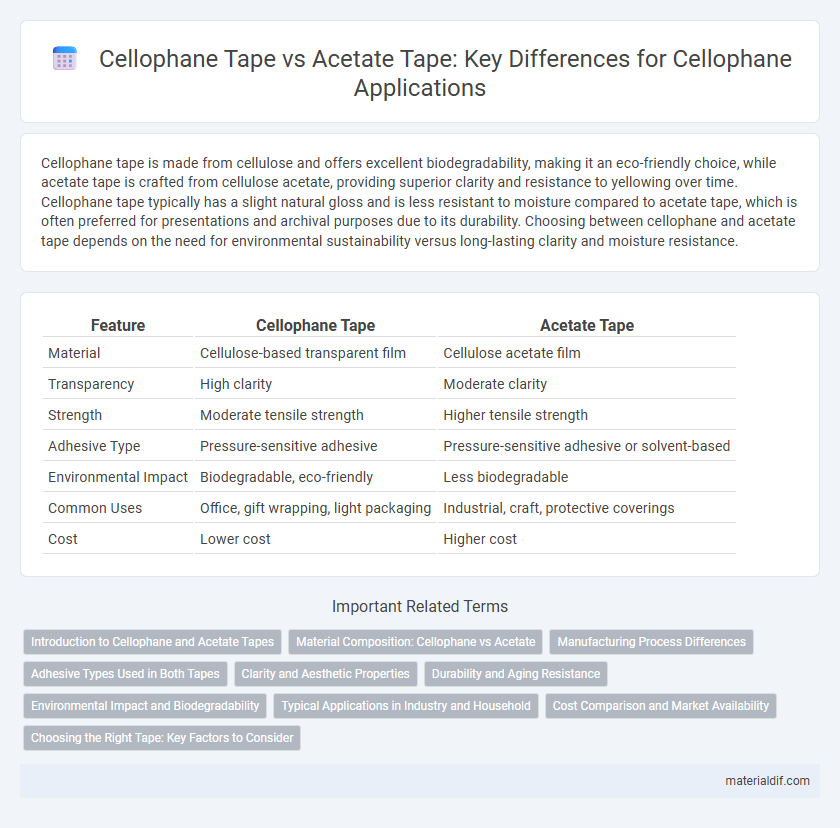

Table of Comparison

| Feature | Cellophane Tape | Acetate Tape |

|---|---|---|

| Material | Cellulose-based transparent film | Cellulose acetate film |

| Transparency | High clarity | Moderate clarity |

| Strength | Moderate tensile strength | Higher tensile strength |

| Adhesive Type | Pressure-sensitive adhesive | Pressure-sensitive adhesive or solvent-based |

| Environmental Impact | Biodegradable, eco-friendly | Less biodegradable |

| Common Uses | Office, gift wrapping, light packaging | Industrial, craft, protective coverings |

| Cost | Lower cost | Higher cost |

Introduction to Cellophane and Acetate Tapes

Cellophane tape is a transparent adhesive tape made from regenerated cellulose derived from wood pulp, known for its clarity and strength. Acetate tape, made from cellulose acetate, offers improved flexibility and chemical resistance compared to cellophane tape. Both tapes serve in packaging, labeling, and crafting, with acetate tape favored for applications requiring durability and higher heat resistance.

Material Composition: Cellophane vs Acetate

Cellophane tape is made from regenerated cellulose derived from wood pulp, providing biodegradability and a natural, transparent finish. Acetate tape consists of cellulose acetate, a synthetic polymer modified through acetylation, which offers increased durability and resistance to moisture. The inherent material differences influence tape flexibility, adhesive compatibility, and environmental impact.

Manufacturing Process Differences

Cellophane tape is manufactured by coating regenerated cellulose film with a pressure-sensitive adhesive, resulting in a biodegradable and transparent product. Acetate tape is produced using cellulose acetate film, which undergoes a plasticization process before adhesive application, providing higher resistance to heat and humidity. The distinct raw materials and film treatments in each process influence the tapes' performance characteristics and environmental impact.

Adhesive Types Used in Both Tapes

Cellophane tape typically uses a natural rubber adhesive, offering strong initial tack and excellent bonding on paper surfaces. Acetate tape commonly features an acrylic adhesive, providing enhanced resistance to aging, yellowing, and environmental factors. The choice of adhesive determines durability, flexibility, and suitability for various applications such as packaging or archival work.

Clarity and Aesthetic Properties

Cellophane tape offers superior clarity with a more transparent, glossy finish that enhances the aesthetic appeal for gift wrapping and crafting. In contrast, acetate tape tends to be less clear, often exhibiting a slight cloudiness or matte texture that can dull the visual presentation. The high transparency of cellophane tape makes it the preferred choice where visual neatness and minimal tape visibility are critical.

Durability and Aging Resistance

Cellophane tape offers moderate durability and tends to yellow and become brittle over time, reducing its aging resistance. Acetate tape, on the other hand, is formulated for superior durability and maintains clarity with minimal discoloration, making it more resistant to aging. This enhanced stability makes acetate tape preferable for archival and long-term applications where longevity is critical.

Environmental Impact and Biodegradability

Cellophane tape is derived from cellulose, a natural polymer extracted from wood pulp, making it biodegradable and more environmentally friendly compared to acetate tape, which is made from synthetic cellulose acetate requiring longer decomposition times. The biodegradability of cellophane tape reduces landfill waste and minimizes pollution, while acetate tape, often coated with plasticizers and adhesives, poses challenges for recycling and increases environmental persistence. Choosing cellophane tape supports sustainability efforts by leveraging renewable resources and enabling more efficient waste management through natural degradation processes.

Typical Applications in Industry and Household

Cellophane tape is widely used in household applications such as gift wrapping, paper mending, and sealing light packages due to its clear appearance and moisture resistance. In industry, acetate tape is preferred for labeling, electrical insulation, and bundling wires because of its higher tensile strength and heat resistance. Both tapes serve distinct roles where cellophane offers flexibility and ease of use, while acetate provides durability and performance under demanding conditions.

Cost Comparison and Market Availability

Cellophane tape typically costs less than acetate tape due to lower production expenses and widespread raw material availability, making it a budget-friendly option for general use. Acetate tape, valued for higher durability and clarity, commands a premium price and is more common in specialty or professional markets. Both tapes maintain strong market presence, but cellophane tape dominates mass-market retail channels, while acetate tape is preferred in niche applications.

Choosing the Right Tape: Key Factors to Consider

Cellophane tape is known for its biodegradability and strong adhesion on paper surfaces, making it ideal for light packaging and gift wrapping, while acetate tape offers greater resistance to heat and moisture, suitable for applications requiring durability. When choosing the right tape, consider factors such as environmental impact, adhesion strength, and the surface material to ensure optimal performance. Cost-efficiency and specific use cases, like archival storage or industrial sealing, also play critical roles in tape selection between cellophane and acetate varieties.

Cellophane Tape vs Acetate Tape Infographic

materialdif.com

materialdif.com