Printed cellophane offers vibrant designs and branding opportunities, enhancing product visibility and appeal, while plain cellophane provides a clear, unobstructed view of the contents, ideal for showcasing product quality. Both types maintain the protective, moisture-resistant qualities of cellophane, ensuring freshness and durability. Choosing between printed and plain cellophane depends on marketing needs and presentation preferences for packaging.

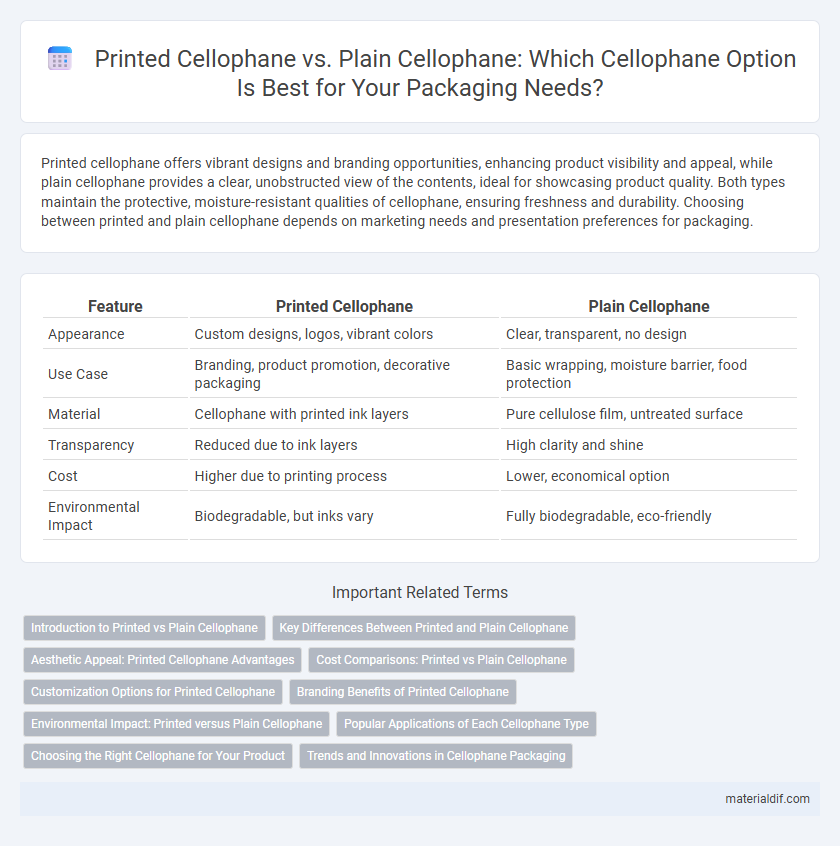

Table of Comparison

| Feature | Printed Cellophane | Plain Cellophane |

|---|---|---|

| Appearance | Custom designs, logos, vibrant colors | Clear, transparent, no design |

| Use Case | Branding, product promotion, decorative packaging | Basic wrapping, moisture barrier, food protection |

| Material | Cellophane with printed ink layers | Pure cellulose film, untreated surface |

| Transparency | Reduced due to ink layers | High clarity and shine |

| Cost | Higher due to printing process | Lower, economical option |

| Environmental Impact | Biodegradable, but inks vary | Fully biodegradable, eco-friendly |

Introduction to Printed vs Plain Cellophane

Printed cellophane enhances packaging by incorporating custom designs, logos, and vibrant colors, making it ideal for branding and product differentiation. Plain cellophane, characterized by its transparent and glossy surface, offers excellent protective qualities while maintaining product visibility. Both types serve essential roles in retail and food industries, balancing aesthetics and functionality based on packaging needs.

Key Differences Between Printed and Plain Cellophane

Printed cellophane features customized designs, logos, or text that enhance brand visibility and product appeal, while plain cellophane offers a transparent, simple protective wrap ideal for showcasing the product itself. The printing process on cellophane involves specialized inks and techniques that maintain flexibility and clarity, whereas plain cellophane provides a cost-effective, moisture-resistant barrier without additional visual embellishment. Printed cellophane is commonly used in retail packaging for marketing purposes, whereas plain cellophane primarily serves practical functions such as preserving freshness and preventing contamination.

Aesthetic Appeal: Printed Cellophane Advantages

Printed cellophane offers enhanced aesthetic appeal through vibrant colors and customizable designs that attract consumer attention and elevate product presentation. This decorative versatility enables brands to showcase logos, patterns, and promotional messages directly on the packaging, increasing brand recognition and market differentiation. Compared to plain cellophane, printed variants create a visually engaging experience that drives impulse purchases and enhances shelf appeal.

Cost Comparisons: Printed vs Plain Cellophane

Printed cellophane incurs higher costs than plain cellophane due to the additional expenses of printing technology, color inks, and design customization. Plain cellophane remains more economical, making it ideal for applications where visual branding is not critical. Businesses seeking to enhance product appeal with vibrant graphics often allocate higher budgets for printed cellophane despite its increased price point.

Customization Options for Printed Cellophane

Printed cellophane offers extensive customization options including vibrant color printing, logos, and intricate patterns tailored to brand identity or special occasions. It supports various ink types and printing techniques such as flexographic and gravure, enhancing the visual appeal and marketing effectiveness of packaging. Custom printed cellophane also allows for precise design placement, making it ideal for promotional packaging and product differentiation.

Branding Benefits of Printed Cellophane

Printed cellophane enhances brand visibility by showcasing logos, colors, and designs directly on the packaging, creating an immediate visual connection with consumers. Custom printed cellophane improves product differentiation on crowded retail shelves, increasing customer recognition and recall. This strategic branding tool supports marketing campaigns by reinforcing brand identity and boosting perceived value without compromising the eco-friendly benefits of cellophane.

Environmental Impact: Printed versus Plain Cellophane

Printed cellophane often involves additional chemical inks and dyes that can increase environmental pollution and complicate recycling processes compared to plain cellophane. Plain cellophane, typically biodegradable and compostable, tends to have a lower ecological footprint due to fewer additives and easier degradation. The production and disposal lifecycle of printed cellophane raises concerns about increased resource use and potential toxicity in contrast to the more sustainable attributes of plain cellophane.

Popular Applications of Each Cellophane Type

Printed cellophane is widely used in retail packaging to enhance brand visibility, commonly seen in food wrapping, gift packaging, and promotional materials where vibrant designs attract consumer attention. Plain cellophane serves functional purposes such as moisture protection and freshness preservation, often utilized in packaging flowers, bakery items, and confectionery products due to its transparency and breathability. The choice between printed and plain cellophane depends on the balance between marketing needs and product protection requirements in various industries.

Choosing the Right Cellophane for Your Product

Printed cellophane enhances product visibility and branding by showcasing logos, patterns, and colors, making it ideal for retail packaging and gift wrapping to attract consumer attention. Plain cellophane offers clarity and moisture resistance without distractions, suitable for displaying the product itself while maintaining freshness and protection. Selecting between printed and plain cellophane depends on marketing goals, product type, and presentation needs to optimize shelf appeal and customer perception.

Trends and Innovations in Cellophane Packaging

Printed cellophane packaging increasingly incorporates digital printing technology, enabling vibrant, high-resolution designs that enhance brand visibility and consumer appeal. Innovations in biodegradable inks and eco-friendly printing methods align with sustainability trends, reducing environmental impact while maintaining aesthetic quality. Plain cellophane remains popular for minimalist and organic product presentations, emphasizing transparency and natural texture, which appeals to eco-conscious consumers seeking simple, recyclable packaging.

Printed Cellophane vs Plain Cellophane Infographic

materialdif.com

materialdif.com