Cellophane is made from cellulose, a natural polymer derived from wood pulp, offering biodegradability and compostability, making it an eco-friendly alternative to plastic films. Polypropylene, a synthetic polymer, is more durable and moisture-resistant but poses environmental challenges due to its slow decomposition and reliance on fossil fuels. Choosing cellulose-based cellophane supports sustainability efforts by reducing plastic waste and enabling easier recycling and natural breakdown.

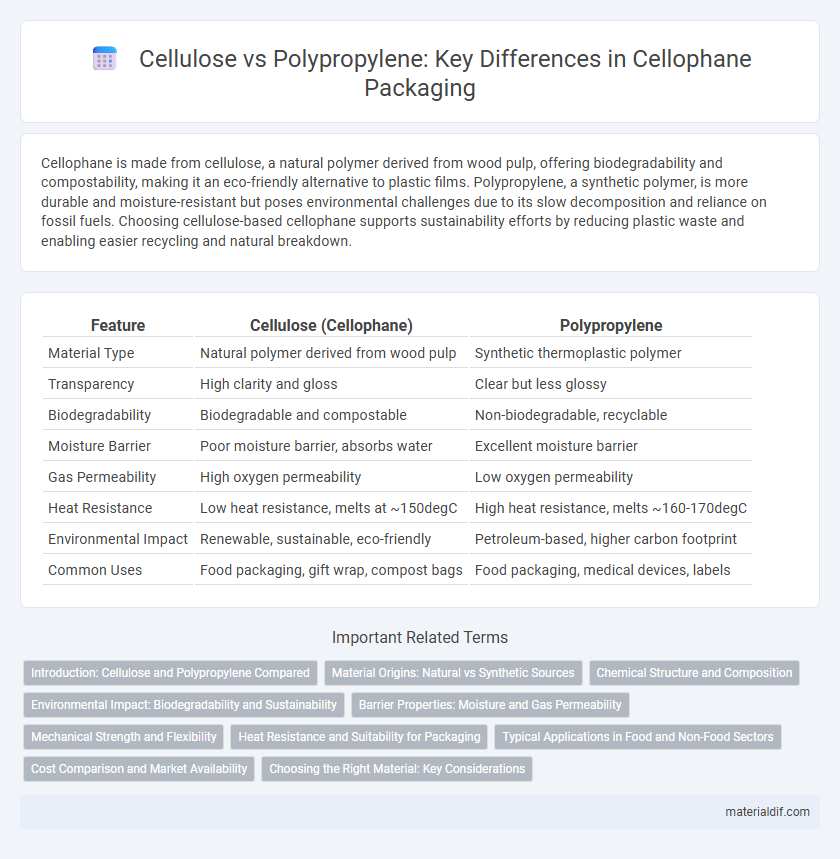

Table of Comparison

| Feature | Cellulose (Cellophane) | Polypropylene |

|---|---|---|

| Material Type | Natural polymer derived from wood pulp | Synthetic thermoplastic polymer |

| Transparency | High clarity and gloss | Clear but less glossy |

| Biodegradability | Biodegradable and compostable | Non-biodegradable, recyclable |

| Moisture Barrier | Poor moisture barrier, absorbs water | Excellent moisture barrier |

| Gas Permeability | High oxygen permeability | Low oxygen permeability |

| Heat Resistance | Low heat resistance, melts at ~150degC | High heat resistance, melts ~160-170degC |

| Environmental Impact | Renewable, sustainable, eco-friendly | Petroleum-based, higher carbon footprint |

| Common Uses | Food packaging, gift wrap, compost bags | Food packaging, medical devices, labels |

Introduction: Cellulose and Polypropylene Compared

Cellulose, derived from plant fibers, is a natural polymer known for its biodegradability and excellent film-forming properties, making it ideal for sustainable packaging. Polypropylene, a synthetic polymer made from propylene monomers, offers high durability, moisture resistance, and cost-effectiveness but lacks biodegradability. Comparing these materials highlights cellulose's environmental benefits versus polypropylene's functional advantages in packaging applications.

Material Origins: Natural vs Synthetic Sources

Cellulose-based cellophane originates from natural sources like wood pulp or cotton fibers, making it biodegradable and renewable. Polypropylene, derived from petrochemicals, is a synthetic polymer produced through polymerization of propylene gas, leading to a non-biodegradable and petroleum-dependent material. The choice between cellulose and polypropylene significantly impacts sustainability and environmental footprint in packaging applications.

Chemical Structure and Composition

Cellulose is a natural polymer composed of linear chains of b-D-glucose units linked by b-1,4-glycosidic bonds, forming a crystalline and biodegradable structure. Polypropylene is a synthetic polymer made from propylene monomers with a hydrocarbon backbone consisting of repeating -CH2-CH(CH3)- units, resulting in a hydrophobic, nonpolar material. The key difference lies in cellulose's oxygen-rich polysaccharide framework, which enables biodegradability, compared to polypropylene's carbon-only hydrocarbon chain contributing to its chemical resistance and durability.

Environmental Impact: Biodegradability and Sustainability

Cellulose-based cellophane is biodegradable and derived from renewable wood pulp, making it a sustainable packaging option that decomposes naturally without leaving harmful residues. In contrast, polypropylene is a petroleum-based plastic that resists biodegradation, contributing significantly to long-term environmental pollution and microplastic accumulation. Using cellulose cellulose reduces carbon footprint and supports circular economy initiatives, whereas polypropylene's production and disposal pose challenges for sustainable waste management.

Barrier Properties: Moisture and Gas Permeability

Cellulose-based cellophane exhibits superior barrier properties against oxygen and carbon dioxide, making it highly effective for preserving the freshness of food products. In contrast, polypropylene offers enhanced moisture resistance due to its hydrophobic nature but allows higher gas permeability compared to cellulose. These differences influence the selection of packaging materials based on specific moisture and gas barrier requirements.

Mechanical Strength and Flexibility

Cellulose-based cellophane exhibits moderate mechanical strength with high flexibility, making it ideal for applications requiring pliability and biodegradability. Polypropylene offers superior mechanical strength and rigidity but lacks the flexibility of cellulose films, resulting in less conformability. This difference influences the selection of packaging materials where durability or flexibility are prioritized.

Heat Resistance and Suitability for Packaging

Cellulose-based cellophane offers moderate heat resistance, making it suitable for packaging products that require breathability and biodegradability but not high-temperature exposure. Polypropylene, a synthetic polymer, provides superior heat resistance and durability, ideal for packaging applications involving hot-fill processes or microwavable foods. Choosing between cellulose and polypropylene depends on balancing environmental sustainability with the need for thermal stability in packaging.

Typical Applications in Food and Non-Food Sectors

Cellulose-based films like cellophane are widely used in food packaging for their biodegradability, moisture barrier properties, and breathability, making them ideal for wrapping fresh produce, confectionery, and bakery items. Polypropylene films dominate in applications requiring higher strength, clarity, and moisture resistance, frequently used for snacks, frozen foods, and non-food packaging such as medical supplies and stationery. Both materials play crucial roles, with cellulose favored for sustainable packaging solutions and polypropylene preferred for durability and cost-effectiveness across food and non-food sectors.

Cost Comparison and Market Availability

Cellulose film, derived from natural polymers, generally incurs higher production costs due to raw material expenses and complex manufacturing processes compared to polypropylene, which benefits from cheaper petrochemical feedstocks and large-scale production. Polypropylene dominates market availability due to its cost-effectiveness and versatile applications in packaging, whereas cellulose film occupies a niche market emphasizing sustainability and biodegradability. Price fluctuations in fossil fuel markets directly affect polypropylene prices, while cellulose film costs remain more stable but higher, influencing buyer preference based on budget and ecological priorities.

Choosing the Right Material: Key Considerations

Selecting between cellulose and polypropylene for packaging hinges on environmental impact, biodegradability, and application requirements. Cellulose, derived from plant fibers, offers biodegradable and compostable properties, making it ideal for eco-friendly packaging, whereas polypropylene provides superior moisture resistance and durability suited for long-term product preservation. Cost-effectiveness, regulatory compliance, and consumer preferences also play crucial roles in determining the optimal material choice for specific packaging needs.

Cellulose vs Polypropylene Infographic

materialdif.com

materialdif.com