Cellulose film and cellophane are both transparent films derived from cellulose but differ in their manufacturing processes and properties. Cellophane is a specific type of cellulose film that undergoes a regeneration process, resulting in a biodegradable, flexible, and moisture-resistant material ideal for food packaging. Unlike synthetic cellulose films, cellophane offers superior breathability and environmental benefits due to its natural origin and biodegradability.

Table of Comparison

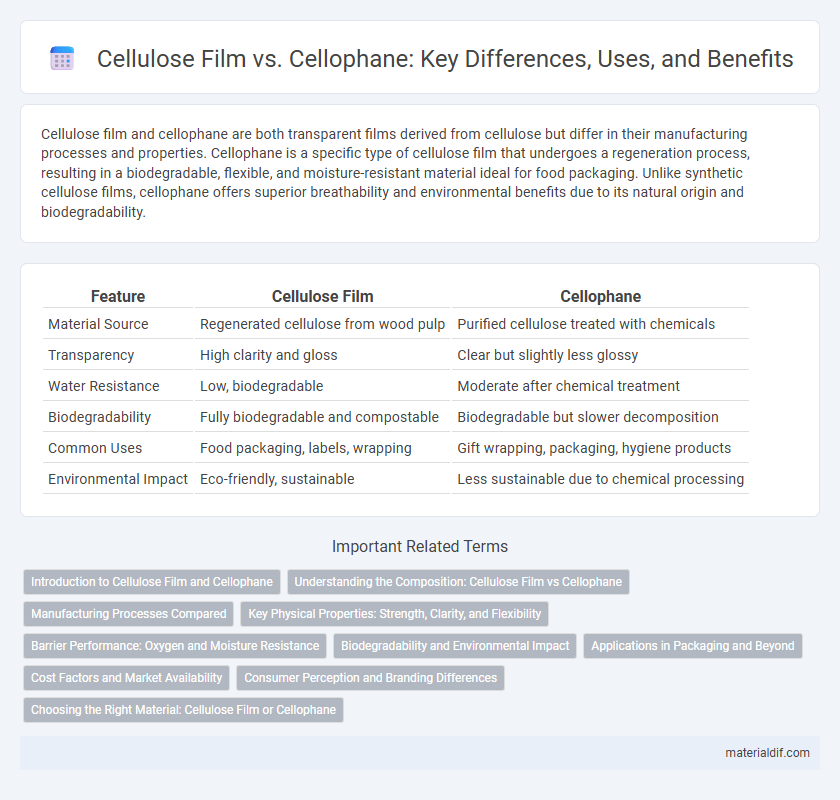

| Feature | Cellulose Film | Cellophane |

|---|---|---|

| Material Source | Regenerated cellulose from wood pulp | Purified cellulose treated with chemicals |

| Transparency | High clarity and gloss | Clear but slightly less glossy |

| Water Resistance | Low, biodegradable | Moderate after chemical treatment |

| Biodegradability | Fully biodegradable and compostable | Biodegradable but slower decomposition |

| Common Uses | Food packaging, labels, wrapping | Gift wrapping, packaging, hygiene products |

| Environmental Impact | Eco-friendly, sustainable | Less sustainable due to chemical processing |

Introduction to Cellulose Film and Cellophane

Cellulose film is a transparent, biodegradable material derived from cellulose, commonly used in packaging for its moisture-resistant properties. Cellophane, a type of cellulose film, is specifically manufactured through a viscose process, resulting in a flexible, heat-sealable film ideal for wrapping food products. Both materials provide eco-friendly alternatives to synthetic plastics, with cellulose film offering broader applications beyond cellophane's traditional use in gift wrapping and food packaging.

Understanding the Composition: Cellulose Film vs Cellophane

Cellulose film and cellophane both derive from cellulose, but cellulose film is typically a regenerated cellulose product made through a more refined extrusion process, resulting in a clearer and more uniform material. Cellophane is produced by chemically treating cellulose with alkalis and carbon disulfide to create viscose, which is then extruded into thin sheets, offering excellent biodegradability and moisture resistance. Understanding these compositional differences highlights why cellulose film boasts superior clarity and mechanical strength, while cellophane remains favored for its natural breathability and eco-friendly properties.

Manufacturing Processes Compared

Cellulose film is typically produced through a chemical process where cellulose is converted into a viscous solution, then regenerated into a transparent film, using methods like the viscose or cuprammonium process. In contrast, cellophane manufacturing involves chemically dissolving cellulose from wood pulp and re-forming it into thin, flexible sheets using the viscose process, followed by washing, bleaching, and plasticizing steps to enhance moisture resistance. The main distinction lies in cellulose film's controlled chemical regeneration yielding diverse film types, while cellophane emphasizes the traditional viscose method optimized for packaging applications.

Key Physical Properties: Strength, Clarity, and Flexibility

Cellulose film and cellophane differ significantly in strength, clarity, and flexibility, with cellulose film generally exhibiting higher tensile strength and enhanced flexibility due to advanced processing techniques. Cellophane offers excellent clarity and glossy appearance but tends to be more brittle and less resistant to tearing compared to cellulose film. The moisture permeability of cellophane also impacts its flexibility, whereas cellulose film benefits from improved moisture barrier properties, making it more versatile for packaging applications.

Barrier Performance: Oxygen and Moisture Resistance

Cellophane and cellulose film both derive from cellulose but differ significantly in barrier performance, particularly against oxygen and moisture. Cellophane typically offers superior oxygen resistance due to its tighter molecular structure achieved through a regeneration process, making it ideal for packaging sensitive products. In contrast, standard cellulose films exhibit higher moisture permeability, which can limit their effectiveness in applications demanding robust moisture barriers.

Biodegradability and Environmental Impact

Cellophane, made from regenerated cellulose, offers superior biodegradability compared to synthetic cellulose films derived from petroleum-based materials. Unlike many cellulose films that contribute to microplastic pollution, cellophane breaks down naturally within weeks, minimizing environmental impact. Its renewable raw material and compostability make cellophane a more sustainable packaging choice in reducing landfill waste and ocean contamination.

Applications in Packaging and Beyond

Cellulose film and cellophane both serve vital roles in packaging, with cellulose film offering superior moisture resistance and flexibility ideal for food packaging, while cellophane excels in breathability, making it suitable for fresh produce and floral wraps. Beyond packaging, cellulose film's clarity and durability support applications in electronics and pharmaceutical blister packs, whereas cellophane's biodegradability and glossy finish are preferred for gift wrapping and decorative purposes. The choice between these materials depends on specific functional requirements like barrier properties, environmental impact, and aesthetic appeal.

Cost Factors and Market Availability

Cellophane, a cellulose-based film, generally costs less than regenerated cellulose film due to simpler manufacturing processes and lower raw material expenses. Cellulose film, often used in specialized packaging, tends to be pricier because of its higher purity and production intricacies. Market availability favors cellophane as it is mass-produced globally, while cellulose film remains niche with limited suppliers and higher price points.

Consumer Perception and Branding Differences

Cellulose film and cellophane differ significantly in consumer perception and branding, with cellophane often viewed as a traditional, eco-friendly packaging material due to its natural, biodegradable cellulose base. In contrast, cellulose film, especially when modified for durability and clarity, is marketed as a high-performance packaging solution, emphasizing its moisture resistance and versatility in food and cosmetic industries. Brands leveraging cellophane typically highlight sustainability and authenticity, while those using cellulose film focus on innovation and enhanced protective qualities.

Choosing the Right Material: Cellulose Film or Cellophane

Cellulose film and cellophane, both derived from cellulose, differ primarily in their manufacturing processes and properties, influencing their suitability for packaging. Cellophane is a traditional, biodegradable film known for its breathability and moisture resistance, ideal for food wrapping and gift packaging, while cellulose film is often engineered for enhanced clarity and strength, making it preferable in industrial applications requiring durability. Selecting the right material depends on factors such as environmental impact, appearance, and mechanical performance tailored to specific packaging needs.

Cellulose Film vs Cellophane Infographic

materialdif.com

materialdif.com