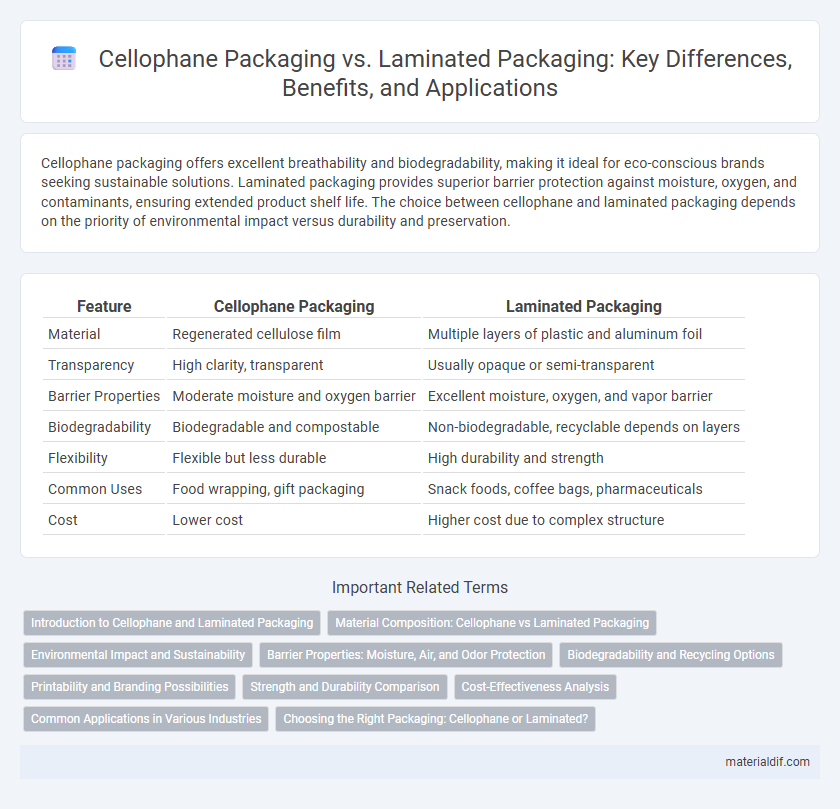

Cellophane packaging offers excellent breathability and biodegradability, making it ideal for eco-conscious brands seeking sustainable solutions. Laminated packaging provides superior barrier protection against moisture, oxygen, and contaminants, ensuring extended product shelf life. The choice between cellophane and laminated packaging depends on the priority of environmental impact versus durability and preservation.

Table of Comparison

| Feature | Cellophane Packaging | Laminated Packaging |

|---|---|---|

| Material | Regenerated cellulose film | Multiple layers of plastic and aluminum foil |

| Transparency | High clarity, transparent | Usually opaque or semi-transparent |

| Barrier Properties | Moderate moisture and oxygen barrier | Excellent moisture, oxygen, and vapor barrier |

| Biodegradability | Biodegradable and compostable | Non-biodegradable, recyclable depends on layers |

| Flexibility | Flexible but less durable | High durability and strength |

| Common Uses | Food wrapping, gift packaging | Snack foods, coffee bags, pharmaceuticals |

| Cost | Lower cost | Higher cost due to complex structure |

Introduction to Cellophane and Laminated Packaging

Cellophane is a transparent, biodegradable film derived from cellulose, widely used for its clarity and moisture resistance in packaging applications. Laminated packaging combines multiple layers of materials, including plastics, aluminum, and paper, to enhance barrier properties, durability, and strength. Both packaging types serve distinct purposes: cellophane offers eco-friendly, breathable packaging ideal for food items, while laminated packaging provides superior protection for extended shelf life and heavy-duty uses.

Material Composition: Cellophane vs Laminated Packaging

Cellophane packaging is made from regenerated cellulose derived from natural plant fibers, offering biodegradability and excellent moisture and aroma barrier properties. Laminated packaging consists of multiple layers of different materials such as plastic films, aluminum foil, and paper, providing enhanced barrier protection, durability, and flexibility for varied applications. The natural origin of cellophane contrasts with the synthetic nature of laminated packaging, influencing environmental impact and recyclability.

Environmental Impact and Sustainability

Cellophane packaging, made from cellulose derived from wood pulp, is biodegradable and compostable, offering a significantly lower environmental impact compared to laminated packaging, which often involves multi-layer plastics that are non-biodegradable and challenging to recycle. Cellophane's renewability and ability to break down naturally reduce landfill waste and pollution, aligning with sustainable packaging goals. In contrast, laminated packaging's reliance on fossil-fuel-based materials and complex recycling processes contributes to higher carbon footprints and persistent environmental waste.

Barrier Properties: Moisture, Air, and Odor Protection

Cellophane packaging offers excellent moisture barrier properties but generally provides moderate protection against air and odors, making it suitable for products requiring breathability. Laminated packaging combines multiple layers of materials, enhancing barrier properties against moisture, air, and odor, thereby extending shelf life and maintaining product freshness. Industries prioritize laminated packaging for goods highly sensitive to contamination or environmental exposure due to its superior sealing and protective attributes.

Biodegradability and Recycling Options

Cellophane packaging is highly biodegradable and compostable, breaking down naturally within a few weeks due to its cellulose base derived from wood pulp. Laminated packaging, often composed of mixed plastics and aluminum layers, poses significant recycling challenges and typically ends up in landfills due to limited recycling facilities capable of separating its components. Choosing cellophane supports eco-friendly waste management by enabling straightforward recycling and reducing environmental impact compared to non-biodegradable laminated alternatives.

Printability and Branding Possibilities

Cellophane packaging offers excellent printability with vibrant, high-resolution graphics that enhance brand visibility through its smooth, transparent surface. Laminated packaging provides more diverse branding possibilities by combining multiple layers and materials, enabling matte or glossy finishes and complex designs for premium appeal. Both options support advanced printing techniques, but cellophane excels in clarity and color vibrancy, ideal for showcasing product freshness and detail.

Strength and Durability Comparison

Cellophane packaging offers natural biodegradability and decent tensile strength but tends to be less durable under moisture exposure compared to laminated packaging. Laminated packaging combines multiple layers of materials, enhancing resistance to punctures, tears, and moisture, providing superior durability for extended shelf life. The multi-material structure of laminated packaging significantly outperforms cellophane in maintaining product integrity during transportation and storage.

Cost-Effectiveness Analysis

Cellophane packaging generally offers a more cost-effective solution for products requiring biodegradability and moderate protection, as it is made from renewable cellulose and has lower raw material costs compared to laminated packaging. Laminated packaging, while more expensive due to multiple protective layers and complex manufacturing, provides superior barrier properties against moisture, oxygen, and contaminants, extending shelf life and reducing product spoilage. Cost-effectiveness depends on product sensitivity and shelf-life requirements, with cellophane favored for eco-friendly, short-term packaging and laminated films preferred for durable, long-term preservation.

Common Applications in Various Industries

Cellophane packaging is widely used in the food industry for wrapping bakery products, confectionery, and fresh produce due to its excellent breathability and biodegradability. Laminated packaging, favored in pharmaceuticals and cosmetics, offers enhanced barrier properties against moisture, oxygen, and UV light, ensuring product safety and extended shelf life. Both packaging types find applications in retail but are chosen based on the specific protection requirements and environmental impact priorities within industries.

Choosing the Right Packaging: Cellophane or Laminated?

Cellophane packaging offers excellent clarity, breathability, and biodegradability, making it ideal for fresh produce and confectionery products. Laminated packaging provides superior barrier properties against moisture, oxygen, and contaminants, extending shelf life for processed and frozen goods. Selecting the right packaging depends on product sensitivity, desired shelf life, and environmental considerations, balancing cellophane's eco-friendliness with laminated film's protective performance.

Cellophane Packaging vs Laminated Packaging Infographic

materialdif.com

materialdif.com