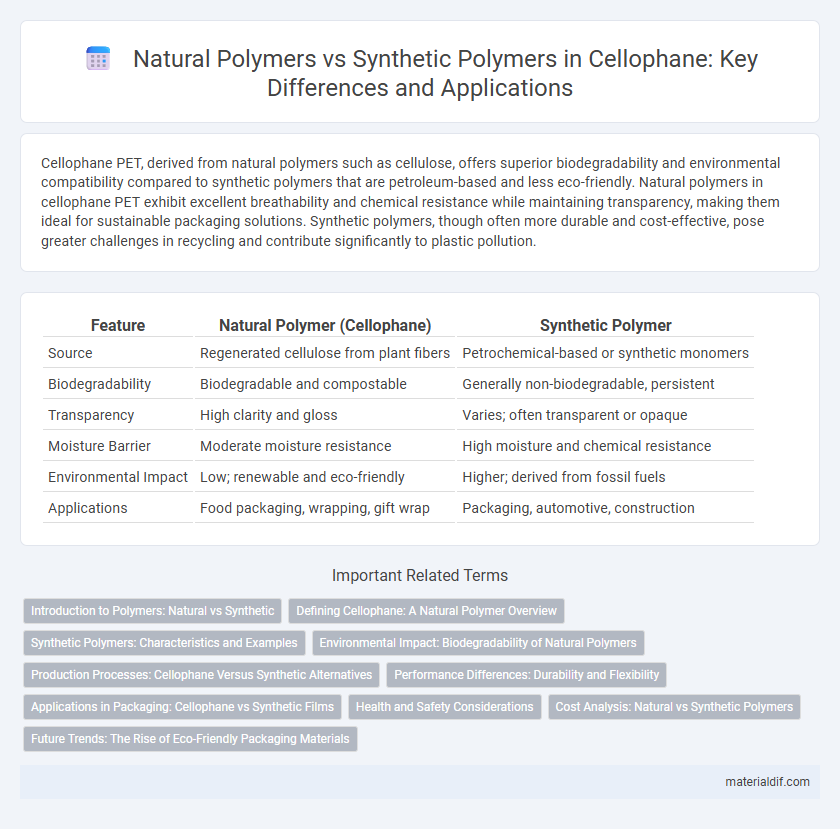

Cellophane PET, derived from natural polymers such as cellulose, offers superior biodegradability and environmental compatibility compared to synthetic polymers that are petroleum-based and less eco-friendly. Natural polymers in cellophane PET exhibit excellent breathability and chemical resistance while maintaining transparency, making them ideal for sustainable packaging solutions. Synthetic polymers, though often more durable and cost-effective, pose greater challenges in recycling and contribute significantly to plastic pollution.

Table of Comparison

| Feature | Natural Polymer (Cellophane) | Synthetic Polymer |

|---|---|---|

| Source | Regenerated cellulose from plant fibers | Petrochemical-based or synthetic monomers |

| Biodegradability | Biodegradable and compostable | Generally non-biodegradable, persistent |

| Transparency | High clarity and gloss | Varies; often transparent or opaque |

| Moisture Barrier | Moderate moisture resistance | High moisture and chemical resistance |

| Environmental Impact | Low; renewable and eco-friendly | Higher; derived from fossil fuels |

| Applications | Food packaging, wrapping, gift wrap | Packaging, automotive, construction |

Introduction to Polymers: Natural vs Synthetic

Natural polymers, such as cellulose in cellophane, are derived from renewable biological sources and exhibit biodegradability and biocompatibility. Synthetic polymers like polyethylene and polystyrene are artificially created through chemical processes, offering customizable properties but often lacking environmental sustainability. Understanding the structural differences and origins of these polymers is crucial for applications in packaging, textiles, and biomedical fields.

Defining Cellophane: A Natural Polymer Overview

Cellophane is a transparent film derived from regenerated cellulose, making it a natural polymer with biodegradable properties. Unlike synthetic polymers such as polyethylene or polypropylene, cellophane is produced from renewable plant-based sources like wood pulp or cotton fibers. Its natural polymer structure offers distinct environmental advantages, including compostability and reduced reliance on petrochemicals.

Synthetic Polymers: Characteristics and Examples

Synthetic polymers are man-made macromolecules characterized by their diverse structures, durability, and resistance to environmental factors, making them highly versatile in industrial applications. Common examples include polyethylene, polystyrene, and polyvinyl chloride, which are widely used in packaging, construction, and consumer goods due to their customizable physical and chemical properties. Unlike natural polymers, synthetic polymers offer consistent quality and can be engineered to achieve specific performance criteria such as tensile strength, flexibility, and thermal stability.

Environmental Impact: Biodegradability of Natural Polymers

Natural polymers like cellophane are highly valued for their biodegradability, breaking down efficiently in composting environments and reducing long-term pollution. Synthetic polymers, derived from petrochemicals, often persist in ecosystems for decades, contributing to plastic waste accumulation and microplastic contamination. The environmental impact of natural polymers is significantly lower due to their renewable sources and ability to decompose without releasing harmful substances.

Production Processes: Cellophane Versus Synthetic Alternatives

Cellophane is produced from natural cellulose derived primarily from wood pulp or cotton fibers, undergoing processes like purification, xanthation, and regeneration to form a transparent film. Synthetic polymers, such as polyethylene or polypropylene, are typically created through chemical polymerization of petrochemical monomers, involving energy-intensive reactions and catalysts. The natural polymer production of cellophane emphasizes renewable biomass sources and biodegradability, contrasting with synthetic alternatives reliant on non-renewable fossil fuels and longer environmental persistence.

Performance Differences: Durability and Flexibility

Natural polymers like cellophane exhibit superior biodegradability and environmental compatibility, yet often lack the durability and flexibility found in synthetic polymers such as polyethylene or polypropylene. Synthetic polymers typically offer enhanced mechanical strength, greater resistance to moisture, and increased flexibility under varying temperature conditions, making them more suitable for applications requiring prolonged use and exposure to stress. Cellophane's limited durability and brittleness can restrict its performance in packaging and industrial applications compared to the adaptable nature of synthetic alternatives.

Applications in Packaging: Cellophane vs Synthetic Films

Cellophane, a natural polymer derived from cellulose, offers excellent biodegradability and breathability, making it ideal for sustainable packaging applications such as food wraps and decorative coverings. Synthetic films like polyethylene or polypropylene provide superior moisture barriers and mechanical strength, widely used in packaging for perishable goods requiring extended shelf life. The choice between cellophane and synthetic films in packaging depends on the balance between environmental impact, biodegradability, and functional performance requirements.

Health and Safety Considerations

Natural polymers like cellophane, derived from cellulose, are biodegradable and generally considered environmentally friendly and non-toxic, reducing health risks associated with chemical exposure. Synthetic polymers, often made from petrochemicals, may release harmful substances such as plasticizers and additives, posing potential health hazards through respiratory or skin contact. Careful selection of packaging materials is essential to minimize exposure to toxic compounds and ensure consumer safety.

Cost Analysis: Natural vs Synthetic Polymers

Natural polymers such as cellophane, derived from cellulose, typically incur higher production costs due to raw material extraction and environmentally friendly processing methods compared to synthetic polymers like polyethylene and polypropylene, which benefit from cheaper petrochemical feedstocks and large-scale manufacturing efficiencies. The biodegradability of natural polymers often justifies their premium price in applications prioritizing sustainability, while synthetic polymers dominate markets driven by cost-effectiveness and durability. Advances in green technology and economies of scale are gradually narrowing the cost gap between natural and synthetic polymers, impacting material selection decisions across industries.

Future Trends: The Rise of Eco-Friendly Packaging Materials

Natural polymers like cellophane, derived from cellulose, offer biodegradability and compostability that synthetic polymers cannot match, positioning them as key materials in sustainable packaging solutions. The future trend in eco-friendly packaging strongly favors natural polymers due to increasing regulatory pressures and consumer demand for reduced plastic waste. Innovations in enhancing the barrier properties and durability of cellophane and other natural polymers aim to expand their use as viable alternatives to traditional synthetic polymers in various industries.

Natural Polymer vs Synthetic Polymer Infographic

materialdif.com

materialdif.com