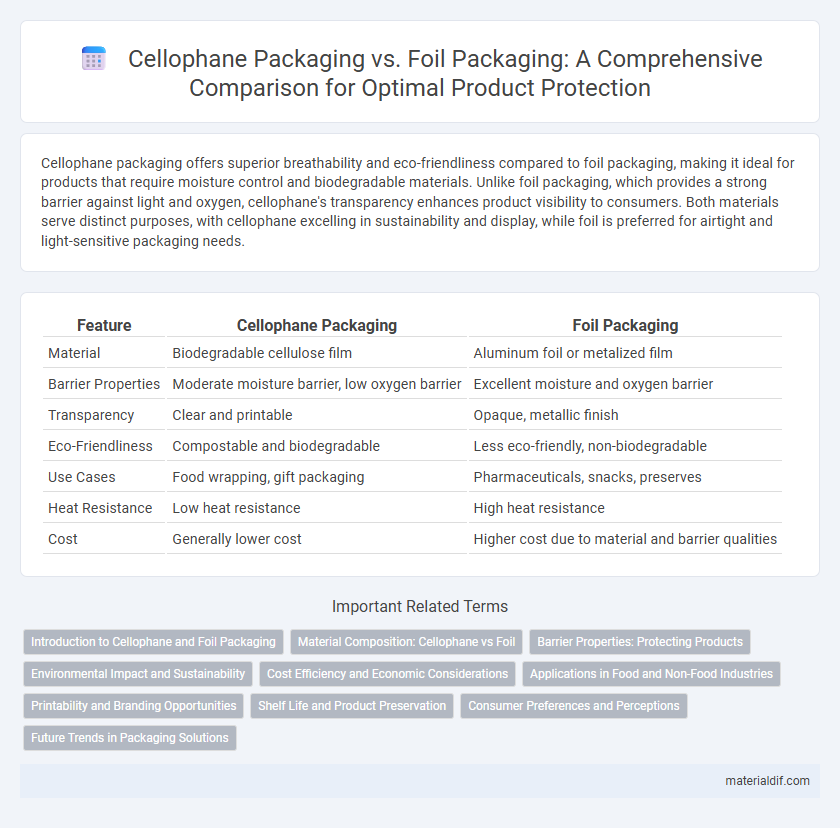

Cellophane packaging offers superior breathability and eco-friendliness compared to foil packaging, making it ideal for products that require moisture control and biodegradable materials. Unlike foil packaging, which provides a strong barrier against light and oxygen, cellophane's transparency enhances product visibility to consumers. Both materials serve distinct purposes, with cellophane excelling in sustainability and display, while foil is preferred for airtight and light-sensitive packaging needs.

Table of Comparison

| Feature | Cellophane Packaging | Foil Packaging |

|---|---|---|

| Material | Biodegradable cellulose film | Aluminum foil or metalized film |

| Barrier Properties | Moderate moisture barrier, low oxygen barrier | Excellent moisture and oxygen barrier |

| Transparency | Clear and printable | Opaque, metallic finish |

| Eco-Friendliness | Compostable and biodegradable | Less eco-friendly, non-biodegradable |

| Use Cases | Food wrapping, gift packaging | Pharmaceuticals, snacks, preserves |

| Heat Resistance | Low heat resistance | High heat resistance |

| Cost | Generally lower cost | Higher cost due to material and barrier qualities |

Introduction to Cellophane and Foil Packaging

Cellophane packaging is a transparent, biodegradable film made from cellulose, offering excellent breathability and moisture resistance, ideal for fresh produce and confectionery. Foil packaging consists of thin sheets of aluminum providing superior barrier properties against light, oxygen, and moisture, commonly used for pharmaceuticals and perishable foods. Both materials enhance product preservation but differ significantly in environmental impact and application suitability.

Material Composition: Cellophane vs Foil

Cellophane packaging is made from regenerated cellulose derived from wood pulp, making it biodegradable and breathable, which helps preserve the freshness of food products. Foil packaging consists primarily of aluminum, offering superior barrier properties against moisture, light, and oxygen, but it is non-biodegradable and less environmentally friendly. The material composition significantly impacts sustainability, flexibility, and product protection, with cellophane favored for eco-conscious applications and foil preferred for high-barrier needs.

Barrier Properties: Protecting Products

Cellophane packaging offers moderate moisture and oxygen barrier properties, making it suitable for products requiring breathability while maintaining freshness. Foil packaging provides superior barrier protection against light, moisture, oxygen, and contaminants, ensuring prolonged product shelf life and optimal preservation. Choosing between cellophane and foil packaging depends on the specific barrier requirements of the product to effectively protect against environmental factors.

Environmental Impact and Sustainability

Cellophane packaging is biodegradable and derived from renewable cellulose sources, making it a more sustainable option compared to foil packaging, which is typically made from non-renewable aluminum and takes longer to decompose. Cellophane's compostability significantly reduces landfill waste and environmental pollution, whereas foil packaging often requires specialized recycling processes that are less accessible. Choosing cellophane promotes eco-friendly packaging solutions by minimizing carbon footprints and supporting circular economy principles.

Cost Efficiency and Economic Considerations

Cellophane packaging generally offers superior cost efficiency compared to foil packaging due to lower raw material and production expenses, making it a budget-friendly choice for large-scale applications. Its biodegradability and renewable cellulose content also contribute to long-term economic benefits by reducing waste disposal costs and enhancing brand appeal in eco-conscious markets. However, foil packaging may incur higher expenses but provides superior barrier properties that can reduce product spoilage, potentially offsetting initial costs with improved shelf life and reduced product loss.

Applications in Food and Non-Food Industries

Cellophane packaging offers superior breathability and biodegradability, making it ideal for fresh produce, bakery items, and confectionery products where moisture control is crucial. Foil packaging provides excellent barrier properties against light, oxygen, and moisture, making it suitable for preserving the shelf life of processed foods, pharmaceuticals, and sensitive electronics. In non-food industries, cellophane is commonly used for wrapping floral bouquets and gift items, while foil packaging is preferred for insulation and protective covers in electronics and automotive sectors.

Printability and Branding Opportunities

Cellophane packaging offers superior printability due to its smooth, transparent surface that allows for vibrant, high-resolution graphics, enhancing branding opportunities with clear visibility of product labels. In contrast, foil packaging often presents challenges for printing, as its metallic surface can cause ink adherence issues, limiting design complexity and color accuracy. Brands seeking impactful visual appeal and detailed artwork typically prefer cellophane for packaging to maximize consumer engagement and brand differentiation.

Shelf Life and Product Preservation

Cellophane packaging offers superior breathability and moisture permeability, which helps maintain freshness in perishable goods by reducing condensation and mold growth. Foil packaging provides an excellent barrier against oxygen, light, and moisture, significantly extending shelf life for sensitive products like chocolates and pharmaceuticals. Choosing between cellophane and foil depends on the specific preservation needs, with foil excelling in long-term protection and cellophane preferred for short-term freshness and eco-friendly solutions.

Consumer Preferences and Perceptions

Consumers often prefer cellophane packaging for its clear, natural appearance that allows product visibility and conveys freshness, which enhances trust and purchase intent. Foil packaging is perceived as more protective due to its superior barrier properties against moisture and light but may be seen as less environmentally friendly and less transparent. Preference shifts toward cellophane in markets valuing sustainability and visual appeal, while foil remains favored for products requiring longer shelf life and enhanced protection.

Future Trends in Packaging Solutions

Cellophane packaging offers biodegradable and renewable advantages, aligning with the growing demand for sustainable materials in future packaging solutions. Foil packaging continues to excel in barrier protection and shelf life extension, but innovations are trending towards hybrid materials combining cellophane's eco-friendliness with foil's durability. Advances in smart packaging and nanotechnology are expected to enhance both cellophane and foil applications, driving the evolution of multifunctional, sustainable packaging systems.

Cellophane Packaging vs Foil Packaging Infographic

materialdif.com

materialdif.com