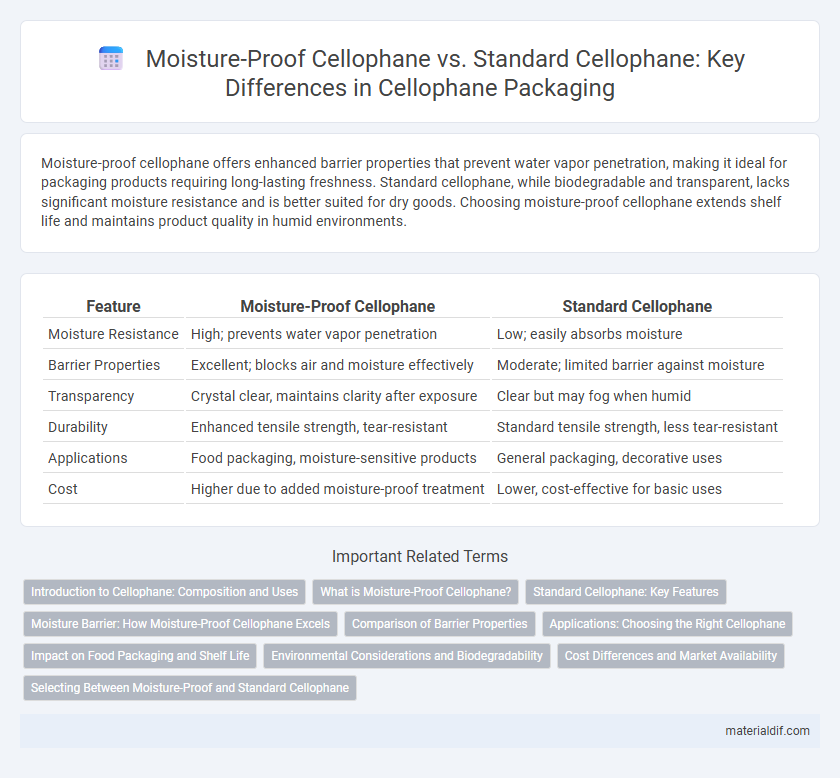

Moisture-proof cellophane offers enhanced barrier properties that prevent water vapor penetration, making it ideal for packaging products requiring long-lasting freshness. Standard cellophane, while biodegradable and transparent, lacks significant moisture resistance and is better suited for dry goods. Choosing moisture-proof cellophane extends shelf life and maintains product quality in humid environments.

Table of Comparison

| Feature | Moisture-Proof Cellophane | Standard Cellophane |

|---|---|---|

| Moisture Resistance | High; prevents water vapor penetration | Low; easily absorbs moisture |

| Barrier Properties | Excellent; blocks air and moisture effectively | Moderate; limited barrier against moisture |

| Transparency | Crystal clear, maintains clarity after exposure | Clear but may fog when humid |

| Durability | Enhanced tensile strength, tear-resistant | Standard tensile strength, less tear-resistant |

| Applications | Food packaging, moisture-sensitive products | General packaging, decorative uses |

| Cost | Higher due to added moisture-proof treatment | Lower, cost-effective for basic uses |

Introduction to Cellophane: Composition and Uses

Moisture-proof cellophane is made by coating traditional cellulose-based film with a waterproof layer, enhancing its resistance to water vapor compared to standard cellophane. Standard cellophane, derived from regenerated cellulose, is biodegradable and widely used for packaging due to its clarity and flexibility but offers limited moisture barrier properties. Both types serve in food packaging, gift wrapping, and protective coverings, with moisture-proof variants preferred for products requiring extended freshness and protection against humidity.

What is Moisture-Proof Cellophane?

Moisture-proof cellophane is a specially treated cellulose film designed to resist water vapor and maintain product freshness by preventing moisture penetration. Unlike standard cellophane, which is naturally permeable to moisture, this variant undergoes chemical modification or coating to enhance its barrier properties. Its application extends to food packaging where controlling humidity is critical for shelf life and quality preservation.

Standard Cellophane: Key Features

Standard cellophane is a biodegradable, transparent film made from regenerated cellulose, offering excellent gas permeability and breathability for packaging applications. It provides a natural, eco-friendly barrier that allows moisture vapor to pass through, which helps in maintaining freshness for dry products but is less effective in moisture protection. Its key features include clarity, flexibility, and grease resistance, making it ideal for wrapping candies, bakery items, and other dry goods where moisture control is less critical.

Moisture Barrier: How Moisture-Proof Cellophane Excels

Moisture-proof cellophane features an advanced moisture barrier layer that significantly reduces water vapor transmission rate (WVTR), preserving product freshness and preventing spoilage. Unlike standard cellophane, which is naturally hydrophilic and allows moisture permeation, the moisture-proof variant employs coatings such as nitrocellulose or polymer blends to enhance water resistance. This improved moisture barrier benefits applications in food packaging, pharmaceuticals, and sensitive electronics by extending shelf life and maintaining product integrity.

Comparison of Barrier Properties

Moisture-proof cellophane exhibits significantly enhanced barrier properties compared to standard cellophane, effectively reducing water vapor transmission rates by up to 50%. This improvement extends shelf life and preserves product integrity in food packaging by preventing moisture ingress. Standard cellophane, while biodegradable and breathable, offers limited protection against humidity, making moisture-proof variants better suited for high-sensitivity applications.

Applications: Choosing the Right Cellophane

Moisture-proof cellophane offers superior water resistance, making it ideal for packaging food products like bakery items, fresh produce, and candies that require extended freshness. Standard cellophane, with its breathability, suits applications such as gift wrapping and floral packaging where moisture retention is less critical. Selecting the right cellophane depends on the product's sensitivity to moisture and the desired shelf life to ensure optimal protection and presentation.

Impact on Food Packaging and Shelf Life

Moisture-proof cellophane provides enhanced barrier properties against water vapor compared to standard cellophane, significantly improving the preservation of food products by preventing moisture ingress and maintaining crispness. This improvement in moisture resistance extends the shelf life of perishable items such as baked goods, fruits, and snacks by reducing spoilage and microbial growth. The use of moisture-proof cellophane in food packaging also supports freshness retention and reduces the need for artificial preservatives, benefiting both manufacturers and consumers.

Environmental Considerations and Biodegradability

Moisture-proof cellophane is typically coated with polymers that enhance water resistance but may reduce biodegradability compared to standard cellophane made from pure cellulose. Standard cellophane, derived from renewable wood pulp, biodegrades more readily in natural environments, making it a more environmentally friendly option. Choosing moisture-proof cellophane requires balancing enhanced functional performance with potential environmental impact due to slower decomposition rates.

Cost Differences and Market Availability

Moisture-proof cellophane generally incurs higher production costs due to specialized coatings that enhance its water resistance, leading to a price premium compared to standard cellophane. Standard cellophane remains widely available and cost-effective for general packaging needs, with lower manufacturing expenses and broader market distribution. The niche demand for moisture-proof variants limits their availability to specific sectors such as food packaging, influencing both pricing and supply dynamics in the packaging industry.

Selecting Between Moisture-Proof and Standard Cellophane

Moisture-proof cellophane offers superior protection against water vapor, making it ideal for packaging items sensitive to humidity, such as fresh produce and pharmaceuticals. Standard cellophane provides basic barrier properties but allows moisture to permeate, which suits dry goods with lower moisture sensitivity. Selecting between moisture-proof and standard cellophane depends on the product's moisture sensitivity, desired shelf life, and packaging environment.

Moisture-Proof Cellophane vs Standard Cellophane Infographic

materialdif.com

materialdif.com