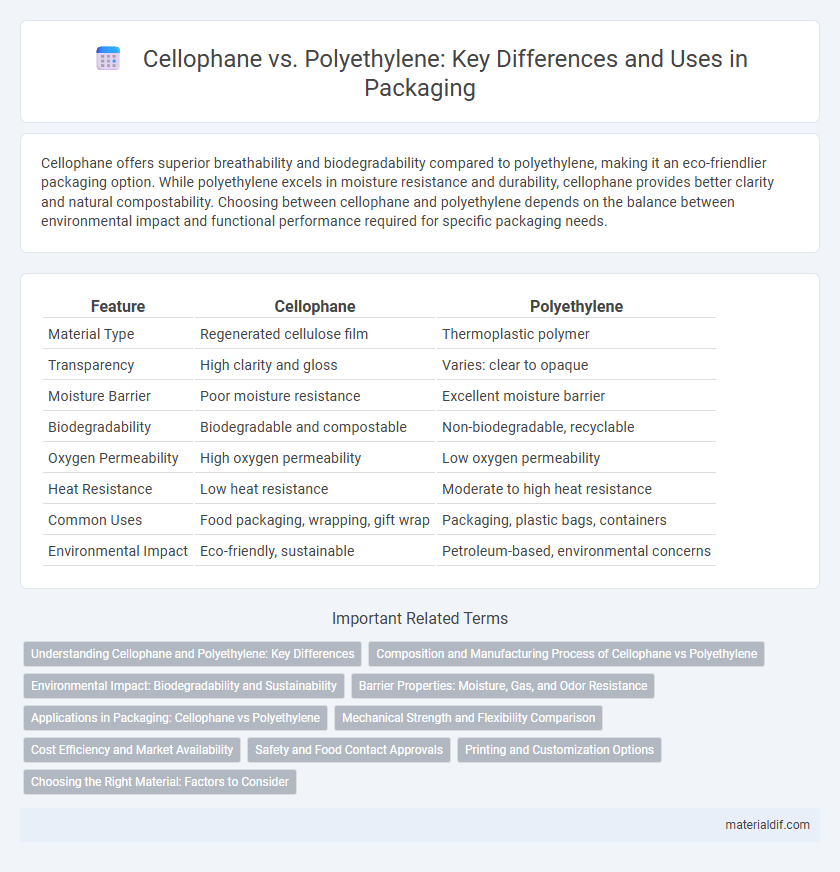

Cellophane offers superior breathability and biodegradability compared to polyethylene, making it an eco-friendlier packaging option. While polyethylene excels in moisture resistance and durability, cellophane provides better clarity and natural compostability. Choosing between cellophane and polyethylene depends on the balance between environmental impact and functional performance required for specific packaging needs.

Table of Comparison

| Feature | Cellophane | Polyethylene |

|---|---|---|

| Material Type | Regenerated cellulose film | Thermoplastic polymer |

| Transparency | High clarity and gloss | Varies: clear to opaque |

| Moisture Barrier | Poor moisture resistance | Excellent moisture barrier |

| Biodegradability | Biodegradable and compostable | Non-biodegradable, recyclable |

| Oxygen Permeability | High oxygen permeability | Low oxygen permeability |

| Heat Resistance | Low heat resistance | Moderate to high heat resistance |

| Common Uses | Food packaging, wrapping, gift wrap | Packaging, plastic bags, containers |

| Environmental Impact | Eco-friendly, sustainable | Petroleum-based, environmental concerns |

Understanding Cellophane and Polyethylene: Key Differences

Cellophane, a biodegradable film made from cellulose, offers superior breathability and clarity compared to polyethylene, a widely used synthetic polymer known for its moisture resistance and flexibility. Unlike polyethylene, cellophane is derived from natural materials, making it an eco-friendly alternative that decomposes more rapidly in the environment. Understanding these differences is crucial for selecting the right packaging material based on sustainability, permeability, and product protection needs.

Composition and Manufacturing Process of Cellophane vs Polyethylene

Cellophane is composed of regenerated cellulose derived from natural sources such as wood pulp or cotton fibers, whereas polyethylene is a synthetic polymer made from ethylene monomers obtained through petroleum refining. The manufacturing process of cellophane involves dissolving cellulose in chemicals to create viscose, which is then extruded through a slit into an acid bath to regenerate the cellulose film; polyethylene is produced via polymerization techniques such as high-pressure or low-pressure polymerization, followed by extrusion or blow molding to form plastic sheets or films. These fundamental differences in composition and manufacturing result in cellophane being biodegradable and breathable, contrasting with the non-biodegradable, moisture-resistant properties of polyethylene films.

Environmental Impact: Biodegradability and Sustainability

Cellophane is biodegradable and derived from renewable cellulose sources, making it a more sustainable packaging option compared to polyethylene, which is petroleum-based and non-biodegradable. The production of cellophane results in fewer greenhouse gas emissions and less environmental pollution, while polyethylene contributes significantly to plastic waste accumulation and microplastic contamination. Cellophane's biodegradability allows it to break down naturally within weeks to months, whereas polyethylene can persist in the environment for hundreds of years, causing long-term ecological harm.

Barrier Properties: Moisture, Gas, and Odor Resistance

Cellophane exhibits superior moisture barrier properties compared to polyethylene, effectively preventing water vapor transmission due to its dense cellulose structure. In terms of gas barrier performance, cellophane also outperforms polyethylene by providing enhanced resistance to oxygen and carbon dioxide permeability, making it ideal for packaging perishable goods. However, polyethylene generally offers better odor resistance, as its hydrophobic nature limits odor molecule penetration more effectively than the hydrophilic cellophane.

Applications in Packaging: Cellophane vs Polyethylene

Cellophane offers superior breathability and biodegradability, making it ideal for packaging fresh produce, bakery goods, and perishables requiring moisture control. Polyethylene excels in moisture resistance and durability, widely used for packaging liquids, frozen foods, and products needing airtight seals. Both materials serve distinct roles in packaging, with cellophane favored for eco-friendly, breathable wraps and polyethylene preferred for robust, moisture-proof barriers.

Mechanical Strength and Flexibility Comparison

Cellophane exhibits lower mechanical strength compared to polyethylene, making it more prone to tearing under stress. Polyethylene offers superior flexibility and tensile strength, allowing it to withstand stretching and bending without damage. These characteristics make polyethylene preferable for applications requiring durable and flexible packaging, while cellophane is favored for its biodegradability despite its limited mechanical resilience.

Cost Efficiency and Market Availability

Cellophane offers moderate cost efficiency compared to polyethylene, which is generally cheaper due to mass production and lower raw material expenses. Market availability favors polyethylene with widespread use in packaging industries, while cellophane remains niche, often preferred for its biodegradability despite higher costs. Cost efficiency and availability metrics position polyethylene as the dominant choice for high-volume applications, whereas cellophane appeals to eco-conscious markets seeking sustainable alternatives.

Safety and Food Contact Approvals

Cellophane is biodegradable and complies with stringent food contact regulations such as FDA and EU standards, ensuring safe use with perishable goods. Polyethylene, widely used in food packaging, is recognized for its excellent barrier properties but may involve additives that require careful regulation compliance to maintain safety. Both materials adhere to food safety certifications, but Cellophane's natural cellulose base offers a lower risk of chemical migration, making it favorable for eco-conscious brands prioritizing health compliance.

Printing and Customization Options

Cellophane offers superior printing clarity and vibrant color reproduction due to its smooth, non-porous surface, making it ideal for high-quality graphics and detailed designs. Polyethylene, while more flexible and cost-effective, often results in less sharp images and limited print resolution, restricting customization options. Businesses prioritizing aesthetic appeal and intricate branding typically prefer cellophane for packaging to enhance visual impact and customer engagement.

Choosing the Right Material: Factors to Consider

Cellophane offers superior biodegradability and oxygen permeability, making it ideal for eco-friendly packaging and preserving freshness in food products. Polyethylene excels in moisture resistance and durability, providing a cost-effective solution for moisture-sensitive goods and long-term storage. Key factors in choosing between cellophane and polyethylene include environmental impact, product preservation needs, and the specific barrier properties required for end-use applications.

Cellophane vs Polyethylene Infographic

materialdif.com

materialdif.com