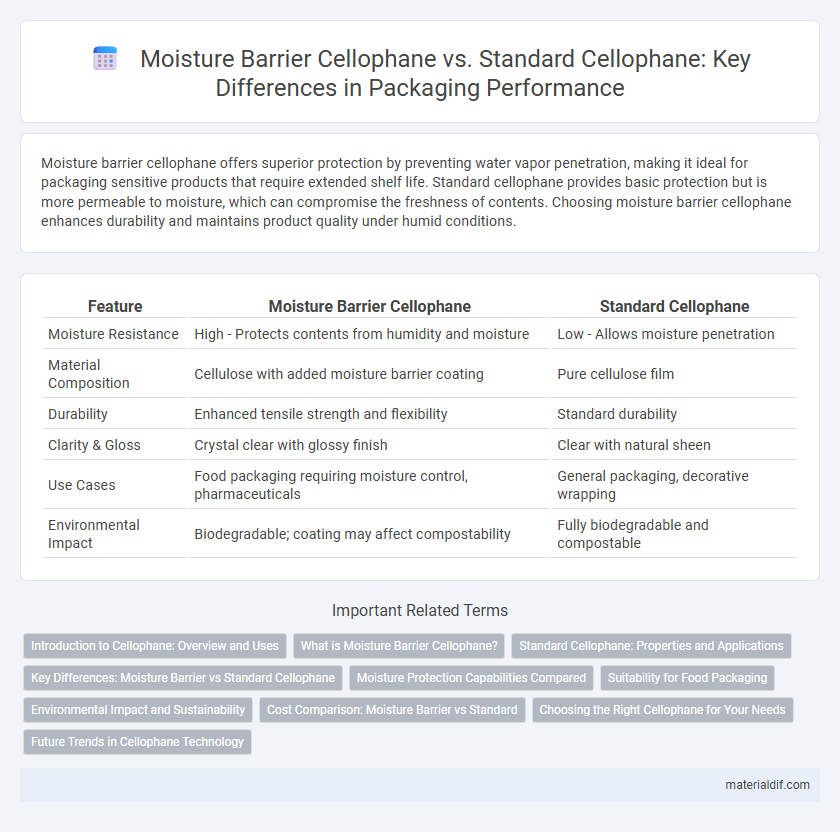

Moisture barrier cellophane offers superior protection by preventing water vapor penetration, making it ideal for packaging sensitive products that require extended shelf life. Standard cellophane provides basic protection but is more permeable to moisture, which can compromise the freshness of contents. Choosing moisture barrier cellophane enhances durability and maintains product quality under humid conditions.

Table of Comparison

| Feature | Moisture Barrier Cellophane | Standard Cellophane |

|---|---|---|

| Moisture Resistance | High - Protects contents from humidity and moisture | Low - Allows moisture penetration |

| Material Composition | Cellulose with added moisture barrier coating | Pure cellulose film |

| Durability | Enhanced tensile strength and flexibility | Standard durability |

| Clarity & Gloss | Crystal clear with glossy finish | Clear with natural sheen |

| Use Cases | Food packaging requiring moisture control, pharmaceuticals | General packaging, decorative wrapping |

| Environmental Impact | Biodegradable; coating may affect compostability | Fully biodegradable and compostable |

Introduction to Cellophane: Overview and Uses

Moisture barrier cellophane provides enhanced protection by preventing water vapor transmission, making it ideal for packaging sensitive food products and pharmaceuticals. Standard cellophane, known for its biodegradability and clarity, is commonly used for wrapping confectionery, flowers, and gift items but offers limited moisture resistance. The choice between moisture barrier and standard cellophane depends on the specific preservation needs and shelf-life requirements of the packaged goods.

What is Moisture Barrier Cellophane?

Moisture barrier cellophane is a specially treated form of cellophane designed to provide enhanced resistance against moisture penetration, making it ideal for packaging perishable goods. Unlike standard cellophane, which is naturally breathable and allows some moisture transfer, moisture barrier cellophane incorporates coatings such as nitrocellulose or resin layers that create an effective seal against water vapor. This innovation extends product shelf life by maintaining optimal humidity levels and protecting contents from environmental moisture.

Standard Cellophane: Properties and Applications

Standard cellophane is a thin, transparent film made from regenerated cellulose, known for its excellent biodegradability and breathability but limited moisture resistance. It offers good gas permeability and a smooth surface, making it ideal for packaging fresh produce, bakery goods, and gift wrapping where moisture control is not critical. Common applications leverage its eco-friendly and aesthetic properties, mainly in packaging that benefits from visualization without requiring significant moisture barrier protection.

Key Differences: Moisture Barrier vs Standard Cellophane

Moisture barrier cellophane offers enhanced protection against water vapor, significantly reducing moisture transmission compared to standard cellophane. Standard cellophane allows moderate air permeability and moisture vapor passage, making it less suitable for moisture-sensitive products. The key difference lies in moisture barrier cellophane's specialized coating or lamination, which improves shelf life and preserves product integrity in humid environments.

Moisture Protection Capabilities Compared

Moisture barrier cellophane offers superior protection against humidity and water vapor compared to standard cellophane, which is more permeable to moisture. The enhanced moisture resistance in barrier cellophane is achieved through specialized coatings or laminates, significantly extending the shelf life of perishable products. Standard cellophane is suitable for basic packaging needs, but moisture barrier variants are essential for applications requiring stringent moisture control.

Suitability for Food Packaging

Moisture barrier cellophane offers superior resistance to water vapor, making it ideal for packaging products sensitive to moisture such as dried fruits, baked goods, and confectionery. Standard cellophane provides excellent breathability but lacks effective moisture protection, which limits its use for long-term storage or high-humidity environments. The enhanced barrier properties of moisture barrier cellophane extend shelf life and preserve product freshness, critical factors in food packaging applications.

Environmental Impact and Sustainability

Moisture barrier cellophane offers enhanced protection by resisting water vapor, reducing product spoilage and waste, which supports sustainability efforts by extending shelf life. Standard cellophane, while biodegradable and compostable, is more permeable to moisture, potentially increasing food waste due to shorter preservation times. Both types are plant-based and biodegradable, but moisture barrier cellophane's improved performance can significantly lower environmental impact through reduced resource use and waste generation.

Cost Comparison: Moisture Barrier vs Standard

Moisture barrier cellophane typically costs 20-30% more than standard cellophane due to its enhanced protective properties against moisture and humidity. The higher price reflects advanced coatings or multilayer structures that extend product shelf life, making it suitable for sensitive items like food or pharmaceuticals. Standard cellophane offers a more affordable option for general packaging needs but lacks the moisture resistance required for high-humidity environments.

Choosing the Right Cellophane for Your Needs

Moisture barrier cellophane offers superior protection against humidity, making it ideal for packaging food items that require extended freshness, such as baked goods and confections. Standard cellophane provides breathability and clarity, suitable for dry products and gift wrapping where moisture resistance is less critical. Selecting the right cellophane depends on the specific moisture sensitivity of your product and the desired shelf life to ensure optimal preservation and presentation.

Future Trends in Cellophane Technology

Moisture barrier cellophane, enhanced with bio-based coatings and nanotechnology, significantly outperforms standard cellophane by providing superior resistance to water vapor transmission, extending product shelf life and reducing food spoilage. Future trends in cellophane technology emphasize the development of fully compostable, high-barrier films that combine environmental sustainability with advanced moisture protection, catering to increasing regulatory demands and consumer preferences for eco-friendly packaging. Innovations such as integrating antimicrobial agents and customizable barrier properties promise to revolutionize cellophane applications across food and pharmaceutical industries, driving growth in biodegradable packaging markets.

Moisture Barrier Cellophane vs Standard Cellophane Infographic

materialdif.com

materialdif.com