Cellophane and PLA film are both biodegradable packaging materials but differ in source and properties. Cellophane is derived from cellulose, making it naturally compostable and breathable, while PLA film is produced from fermented plant starch, offering a clearer appearance and stronger moisture barrier. Choosing between cellophane and PLA film depends on specific packaging needs such as biodegradability, transparency, and moisture resistance.

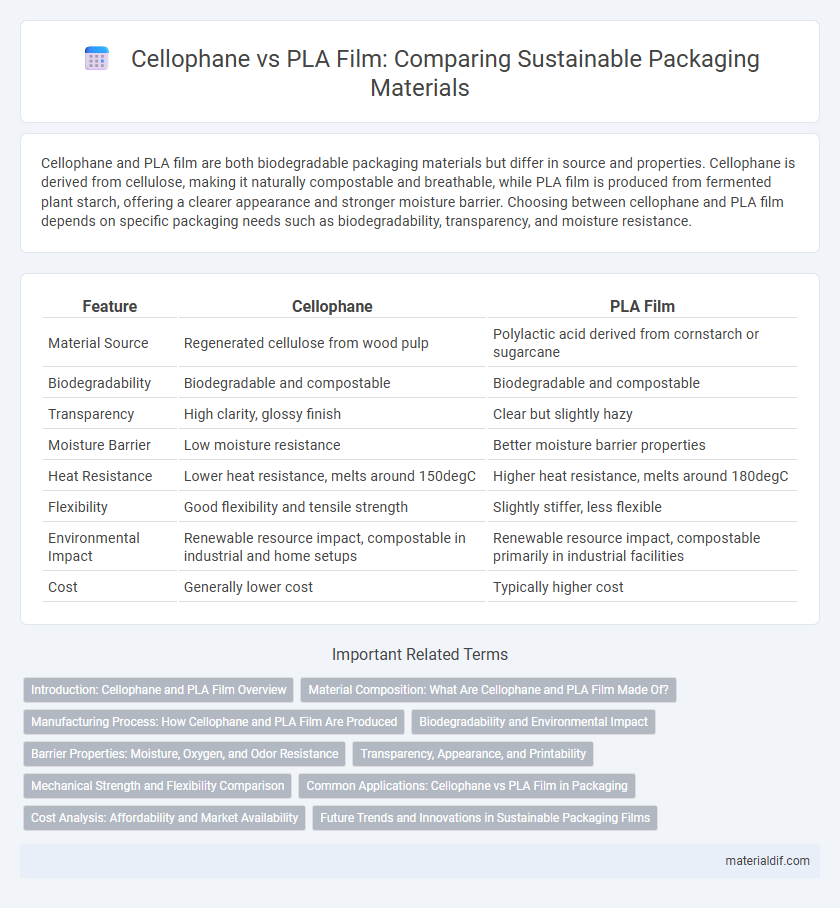

Table of Comparison

| Feature | Cellophane | PLA Film |

|---|---|---|

| Material Source | Regenerated cellulose from wood pulp | Polylactic acid derived from cornstarch or sugarcane |

| Biodegradability | Biodegradable and compostable | Biodegradable and compostable |

| Transparency | High clarity, glossy finish | Clear but slightly hazy |

| Moisture Barrier | Low moisture resistance | Better moisture barrier properties |

| Heat Resistance | Lower heat resistance, melts around 150degC | Higher heat resistance, melts around 180degC |

| Flexibility | Good flexibility and tensile strength | Slightly stiffer, less flexible |

| Environmental Impact | Renewable resource impact, compostable in industrial and home setups | Renewable resource impact, compostable primarily in industrial facilities |

| Cost | Generally lower cost | Typically higher cost |

Introduction: Cellophane and PLA Film Overview

Cellophane is a thin, transparent film made from regenerated cellulose derived from wood pulp, offering excellent breathability and biodegradability. PLA film, produced from polylactic acid sourced from renewable resources like corn starch, provides a compostable alternative with strong barrier properties against moisture and oxygen. Both materials serve as sustainable packaging options, with cellophane excelling in clarity and biodegradability, while PLA film offers enhanced moisture resistance and compostability.

Material Composition: What Are Cellophane and PLA Film Made Of?

Cellophane is made from regenerated cellulose derived from wood pulp or cotton fibers, offering biodegradability due to its natural origin. PLA film, or polylactic acid film, is synthesized from fermented plant starch, typically corn or sugarcane, making it a compostable bioplastic. Both materials emphasize sustainability but differ fundamentally in their organic source and production process.

Manufacturing Process: How Cellophane and PLA Film Are Produced

Cellophane is produced by dissolving cellulose from wood pulp, cotton, or hemp in alkali and carbon disulfide to create viscose, which is then extruded, regenerated, and stretched into thin transparent sheets. PLA film is manufactured through fermenting plant starch, typically corn, to produce polylactic acid, followed by polymerization, melting, and film extrusion or casting to form biodegradable plastic sheets. The distinct raw materials and chemical processes define the sustainability profiles and physical properties of cellophane and PLA film.

Biodegradability and Environmental Impact

Cellophane, made from cellulose derived from wood pulp, offers superior biodegradability as it fully decomposes in soil and water within weeks, unlike PLA film which requires industrial composting conditions for effective breakdown. The environmental impact of cellophane is generally lower due to its renewable raw materials and minimal toxic residue after degradation, while PLA film production involves fermenting corn starch that can strain agricultural resources. Both materials are biodegradable alternatives to conventional plastics, but cellophane's natural cellulose base ensures a more eco-friendly lifecycle in typical environmental settings.

Barrier Properties: Moisture, Oxygen, and Odor Resistance

Cellophane offers excellent moisture barrier properties, effectively preventing water vapor transmission, which is crucial for preserving food freshness. PLA film generally provides superior oxygen barrier performance, reducing oxidation and extending shelf life in packaging applications. Both materials exhibit moderate odor resistance, but cellophane's natural cellulose composition typically results in better containment of volatile compounds compared to PLA films.

Transparency, Appearance, and Printability

Cellophane offers superior transparency with a natural glossy finish, making it ideal for products requiring clear visibility and an appealing appearance, while PLA film typically presents a matte look with slightly less clarity. The printability of cellophane is enhanced due to its smooth surface, allowing vibrant and sharp graphics, whereas PLA film may require additional coatings to achieve comparable print quality. Both materials are biodegradable, but cellophane's aesthetic and printing properties make it preferable for high-end packaging where visual presentation is critical.

Mechanical Strength and Flexibility Comparison

Cellophane exhibits moderate tensile strength but tends to be brittle, limiting its flexibility under stress, which can result in cracking or tearing. PLA film demonstrates higher mechanical strength and superior flexibility due to its polymer structure, allowing it to withstand stretching and bending without damage. When comparing both, PLA film offers enhanced durability and elasticity, making it more suitable for applications requiring a balance of strength and flexibility.

Common Applications: Cellophane vs PLA Film in Packaging

Cellophane is widely used for packaging fresh produce, confectionery, and bakery items due to its excellent breathability and moisture barrier properties, preserving product freshness. PLA film is favored in sustainable packaging for snack wrappers, compostable bags, and food containers because it is biodegradable and derived from renewable resources. Both materials serve key roles in eco-friendly packaging but differ in application based on their environmental impact and barrier performance.

Cost Analysis: Affordability and Market Availability

Cellophane is generally more affordable than PLA film due to lower production costs and established manufacturing processes, making it a cost-effective choice for packaging. PLA film, derived from renewable resources like cornstarch, tends to be more expensive because of its bio-based production and relatively limited large-scale availability. Market availability favors cellophane with widespread distribution and numerous suppliers, whereas PLA film remains niche with higher costs linked to emerging bio-plastics markets.

Future Trends and Innovations in Sustainable Packaging Films

Cellophane and PLA film represent two key materials driving the sustainable packaging revolution, with cellophane offering exceptional biodegradability and moisture resistance derived from cellulose fibers. Future innovations are focusing on enhancing the mechanical strength and barrier properties of PLA films through bio-based additives and nanocomposite technologies, aiming to compete more effectively with traditional plastics. As sustainability regulations tighten globally, the market demand for hybrid films combining cellophane's natural compostability and PLA's renewable sourcing is expected to accelerate growth in eco-friendly packaging solutions.

Cellophane vs PLA Film Infographic

materialdif.com

materialdif.com