Cellophane is a cellulose-based film derived from natural plant fibers, making it biodegradable and environmentally friendly compared to synthetic polymer films, which are petroleum-based and contribute to plastic pollution. Cellulose-based films offer excellent breathability and moisture control, ideal for food packaging applications, while synthetic polymers provide superior strength and water resistance but lack eco-friendly attributes. Choosing cellophane film supports sustainable packaging solutions without compromising essential functional properties.

Table of Comparison

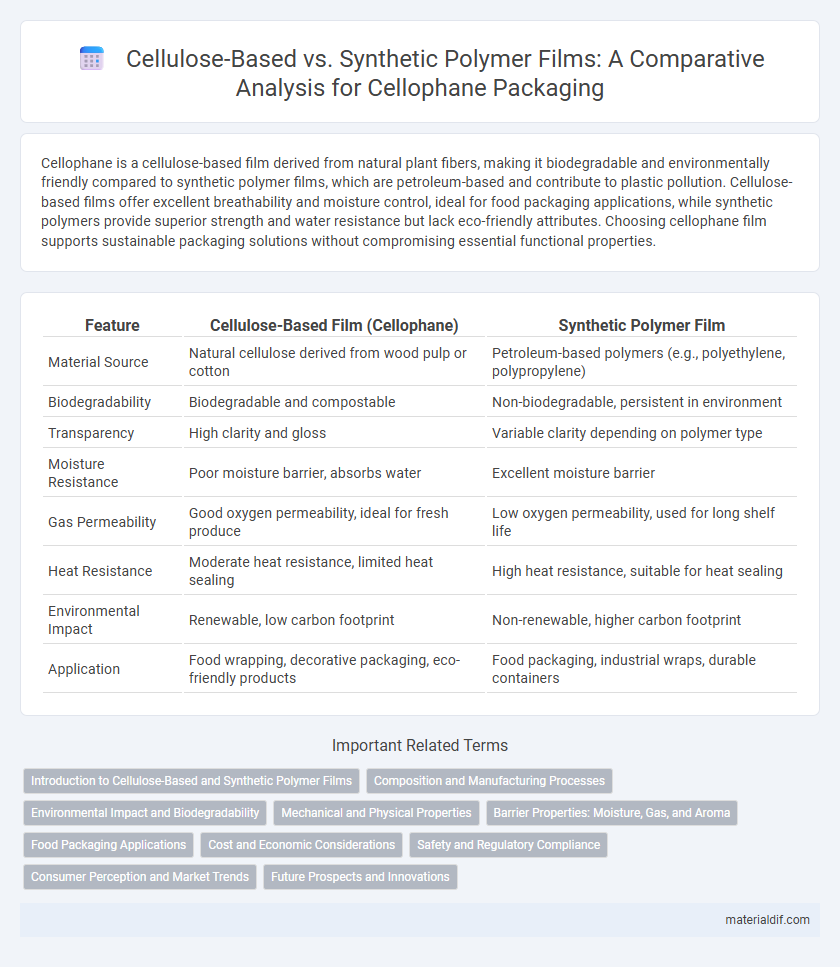

| Feature | Cellulose-Based Film (Cellophane) | Synthetic Polymer Film |

|---|---|---|

| Material Source | Natural cellulose derived from wood pulp or cotton | Petroleum-based polymers (e.g., polyethylene, polypropylene) |

| Biodegradability | Biodegradable and compostable | Non-biodegradable, persistent in environment |

| Transparency | High clarity and gloss | Variable clarity depending on polymer type |

| Moisture Resistance | Poor moisture barrier, absorbs water | Excellent moisture barrier |

| Gas Permeability | Good oxygen permeability, ideal for fresh produce | Low oxygen permeability, used for long shelf life |

| Heat Resistance | Moderate heat resistance, limited heat sealing | High heat resistance, suitable for heat sealing |

| Environmental Impact | Renewable, low carbon footprint | Non-renewable, higher carbon footprint |

| Application | Food wrapping, decorative packaging, eco-friendly products | Food packaging, industrial wraps, durable containers |

Introduction to Cellulose-Based and Synthetic Polymer Films

Cellulose-based films, derived from natural cellulose fibers, offer biodegradable and renewable alternatives to synthetic polymer films made from petroleum-based materials like polyethylene and polypropylene. These films exhibit superior oxygen permeability and compostability, making them ideal for sustainable packaging applications. Synthetic polymer films provide enhanced mechanical strength, moisture resistance, and cost-effectiveness, widely utilized in industrial and consumer product packaging.

Composition and Manufacturing Processes

Cellulose-based film is derived from natural cellulose fibers sourced from wood pulp or cotton, undergoing a process of purification, dissolution, and regeneration to form a biodegradable, transparent film. Synthetic polymer films such as polyethylene or polypropylene are produced through polymerization of petrochemical monomers, involving extrusion or casting techniques that yield durable, moisture-resistant materials. The key distinctions lie in cellulose film's renewable biomass origin and eco-friendly manufacturing methods compared to the fossil fuel dependency and energy-intensive synthesis of synthetic polymers.

Environmental Impact and Biodegradability

Cellulose-based films, derived from natural polymers like wood pulp, exhibit superior biodegradability and lower environmental impact compared to synthetic polymer films, which are primarily petroleum-based and persist in ecosystems for decades. These biodegradable films break down into non-toxic components through microbial activity, reducing landfill waste and marine pollution. In contrast, synthetic polymer films contribute significantly to microplastic pollution due to their resistance to natural degradation processes.

Mechanical and Physical Properties

Cellulose-based films exhibit superior biodegradability and oxygen permeability compared to synthetic polymer films, making them ideal for sustainable packaging applications. Their mechanical properties, including tensile strength and flexibility, often result in a more natural feel but can be less durable under high humidity or stress conditions than synthetic alternatives like polyethylene or polypropylene. Synthetic polymer films provide higher moisture resistance and greater mechanical durability, making them preferred in applications requiring robust barrier properties and longer shelf life.

Barrier Properties: Moisture, Gas, and Aroma

Cellulose-based films exhibit superior moisture barrier properties compared to synthetic polymer films due to their dense hydrogen-bonded network, which limits water vapor transmission effectively. However, synthetic polymer films typically outperform cellulose-based films in gas barrier performance, particularly oxygen and carbon dioxide, owing to their tailored molecular structures and crystallinity levels. Aroma retention is generally enhanced in synthetic polymer films, as their hydrophobic nature minimizes the diffusion of volatile compounds, whereas cellulose-based films may allow higher aroma permeation due to their hydrophilic characteristics.

Food Packaging Applications

Cellulose-based films, derived from natural polymers, offer superior biodegradability and oxygen permeability control compared to synthetic polymer films, making them ideal for sustainable food packaging applications. Their renewable origin reduces environmental impact, while maintaining effective barrier properties that preserve food freshness and extend shelf life. Synthetic polymer films, although highly durable and moisture-resistant, often contribute to plastic pollution due to their non-biodegradable nature and reliance on petrochemical resources.

Cost and Economic Considerations

Cellulose-based film generally incurs higher production costs due to its raw material sourcing and more complex manufacturing processes compared to synthetic polymer films, which leverage cheaper petrochemical feedstocks and large-scale production efficiencies. Despite the initial expense, cellulose films offer economic advantages in biodegradability and reduced environmental impact, potentially lowering long-term costs related to waste management and regulatory compliance. Market trends indicate increasing demand for sustainable packaging materials, which may shift cost dynamics favoring cellulose-based films as consumer and governmental pressures grow.

Safety and Regulatory Compliance

Cellulose-based films, derived from natural polymers, offer superior biodegradability and reduced toxicity compared to synthetic polymer films, making them safer for food packaging applications. Regulatory agencies like the FDA and EFSA increasingly favor cellulose films due to their compliance with strict migration limits and environmental safety standards. Conversely, synthetic polymer films often contain additives and plasticizers that may raise concerns over chemical leaching and regulatory restrictions in various markets.

Consumer Perception and Market Trends

Cellulose-based films, derived from natural materials like wood pulp, are increasingly favored by environmentally conscious consumers due to their biodegradability and compostability, contrasting with synthetic polymer films typically made from petroleum-based plastics. Market trends reveal a growing demand for sustainable packaging solutions, with consumers perceiving cellulose films as a premium, eco-friendly alternative that aligns with green initiatives and regulatory pressures. Despite synthetic polymer films' dominance in durability and cost-effectiveness, the shift towards circular economy principles is driving investment and innovation in cellulose-based film technologies.

Future Prospects and Innovations

Cellulose-based films, derived from renewable resources, are gaining traction for their biodegradability and reduced environmental impact compared to synthetic polymer films made from petrochemicals. Innovations in nanocellulose and bio-based additives are enhancing mechanical strength, barrier properties, and transparency, positioning cellulose films as viable alternatives in packaging industries. Future prospects include advanced recycling methods and integration with smart packaging technologies, driving sustainable development and reducing plastic pollution globally.

Cellulose-Based Film vs Synthetic Polymer Film Infographic

materialdif.com

materialdif.com