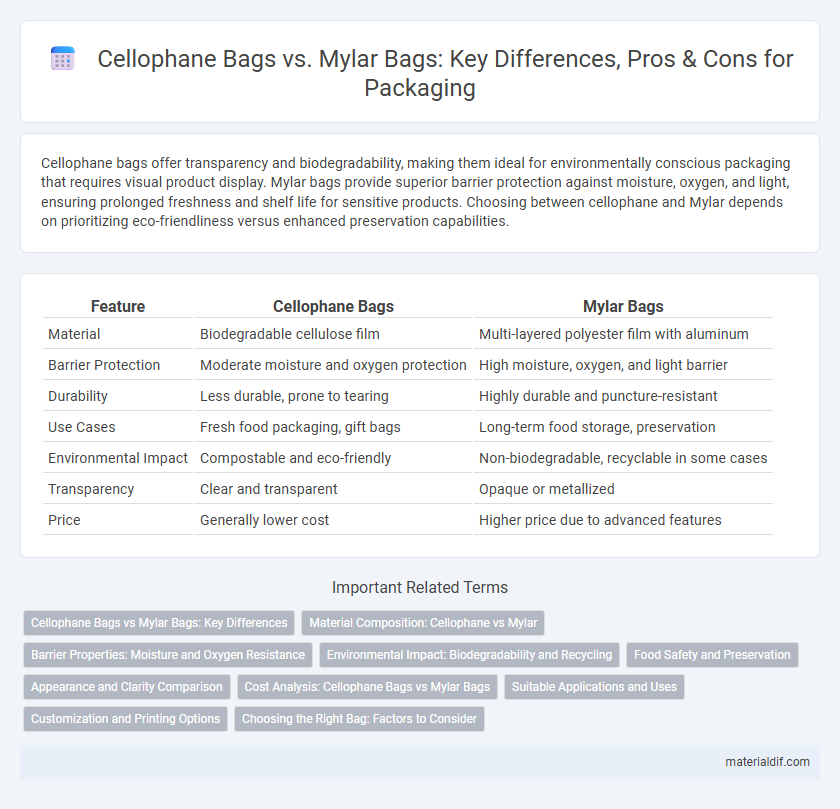

Cellophane bags offer transparency and biodegradability, making them ideal for environmentally conscious packaging that requires visual product display. Mylar bags provide superior barrier protection against moisture, oxygen, and light, ensuring prolonged freshness and shelf life for sensitive products. Choosing between cellophane and Mylar depends on prioritizing eco-friendliness versus enhanced preservation capabilities.

Table of Comparison

| Feature | Cellophane Bags | Mylar Bags |

|---|---|---|

| Material | Biodegradable cellulose film | Multi-layered polyester film with aluminum |

| Barrier Protection | Moderate moisture and oxygen protection | High moisture, oxygen, and light barrier |

| Durability | Less durable, prone to tearing | Highly durable and puncture-resistant |

| Use Cases | Fresh food packaging, gift bags | Long-term food storage, preservation |

| Environmental Impact | Compostable and eco-friendly | Non-biodegradable, recyclable in some cases |

| Transparency | Clear and transparent | Opaque or metallized |

| Price | Generally lower cost | Higher price due to advanced features |

Cellophane Bags vs Mylar Bags: Key Differences

Cellophane bags are biodegradable and allow for natural breathability, making them ideal for packaging fresh produce and bakery items, while Mylar bags offer superior barrier protection against moisture, oxygen, and light, which is essential for long-term food storage. The transparency of cellophane bags provides clear product visibility, whereas Mylar bags are typically opaque or metallic, enhancing protection but limiting visibility. Cellophane bags are less durable and more susceptible to tearing compared to the puncture-resistant and heat-sealable Mylar bags, which contribute to their extended shelf-life and robust preservation qualities.

Material Composition: Cellophane vs Mylar

Cellophane bags are made from regenerated cellulose derived from wood pulp, making them biodegradable and moisture-resistant but less durable against punctures compared to Mylar bags. Mylar bags consist of multiple layers of metalized polyester film, providing superior barrier properties against oxygen, moisture, and light, resulting in enhanced preservation of contents. The distinct material compositions influence the bags' environmental impact, shelf-life performance, and suitability for various packaging applications.

Barrier Properties: Moisture and Oxygen Resistance

Cellophane bags offer moderate moisture resistance but have limited oxygen barrier properties, making them less effective for long-term preservation of sensitive products. Mylar bags provide superior barrier properties against both moisture and oxygen due to their multi-layered metallic film construction, ensuring extended freshness and protection. These enhanced barrier characteristics make Mylar bags the preferred choice for packaging items that require high resistance to environmental factors.

Environmental Impact: Biodegradability and Recycling

Cellophane bags are made from cellulose, a natural polymer derived from wood pulp, making them biodegradable and compostable within weeks under the right conditions. Mylar bags consist of polyester film derived from petroleum, which is not biodegradable but can be recycled if processed through specialized facilities. The environmental impact favors cellophane for its eco-friendly degradation, whereas Mylar's recycling depends heavily on local infrastructure and consumer participation.

Food Safety and Preservation

Cellophane bags offer excellent breathability, making them ideal for packaging fresh produce and baked goods by reducing moisture buildup and extending shelf life without trapping humidity. Mylar bags provide superior food safety through their multi-layered, metalized polyester construction, creating an airtight, light-resistant barrier that preserves food freshness and prevents spoilage from oxygen and contaminants. For long-term food preservation, Mylar bags outperform cellophane by protecting contents from environmental factors, while cellophane remains a sustainable and biodegradable option for short-term storage.

Appearance and Clarity Comparison

Cellophane bags offer a natural, translucent appearance with high clarity, allowing products to be easily visible while maintaining an eco-friendly image. Mylar bags, on the other hand, have a metallic, reflective surface that provides an opaque look and enhanced barrier protection but limits product visibility. The choice between cellophane and mylar bags depends on the need for clear product display versus superior protection and shelf appeal.

Cost Analysis: Cellophane Bags vs Mylar Bags

Cellophane bags typically cost less upfront compared to Mylar bags, making them a budget-friendly option for short-term packaging needs. Mylar bags, while more expensive, offer superior barrier properties and durability, which can reduce long-term costs by preserving product freshness and reducing waste. For businesses prioritizing cost-efficiency, cellophane bags are ideal for disposable packaging, whereas Mylar bags justify their higher price through enhanced protection and extended shelf life.

Suitable Applications and Uses

Cellophane bags are ideal for packaging fresh produce, baked goods, and floral arrangements due to their biodegradability and breathability, which help maintain product freshness while allowing moisture to escape. Mylar bags provide superior moisture and oxygen barriers, making them suitable for long-term food storage, freeze-drying, and packaging sensitive materials such as electronics or pharmaceuticals. Each bag type serves distinct purposes based on product protection needs and environmental considerations.

Customization and Printing Options

Cellophane bags offer versatile customization with high-quality, clear printing suitable for vibrant logos and intricate designs, enhancing product visibility and branding. Mylar bags provide advanced printing options, including metallic finishes and multi-layered color prints, ideal for premium product presentation and durability. Both materials support custom shapes and sizes, but Mylar excels in protective features, while cellophane prioritizes clarity and eco-friendly appeal.

Choosing the Right Bag: Factors to Consider

Cellophane bags offer biodegradability and excellent breathability, making them ideal for packaging fresh produce and delicate items, while Mylar bags provide superior barrier properties against moisture, oxygen, and light, extending shelf life for sensitive products like dried foods and electronics. When choosing the right bag, consider factors such as product sensitivity, required shelf life, environmental impact, and storage conditions to ensure optimal protection and sustainability. Cost-effectiveness and sealing method compatibility are also crucial, as Mylar bags often require heat sealing, whereas cellophane bags can use simpler closures.

Cellophane Bags vs Mylar Bags Infographic

materialdif.com

materialdif.com