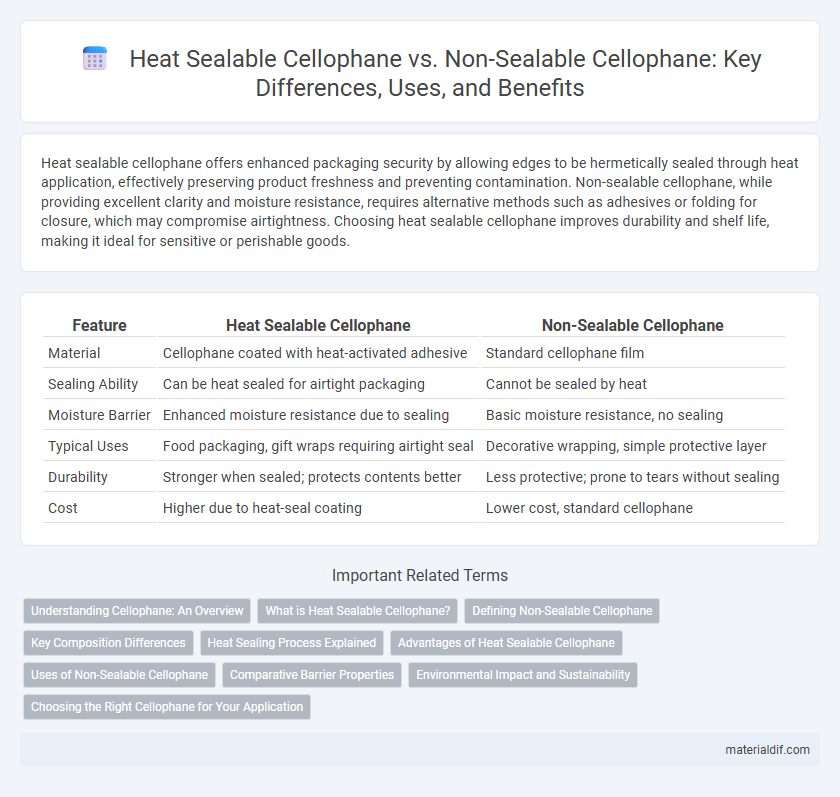

Heat sealable cellophane offers enhanced packaging security by allowing edges to be hermetically sealed through heat application, effectively preserving product freshness and preventing contamination. Non-sealable cellophane, while providing excellent clarity and moisture resistance, requires alternative methods such as adhesives or folding for closure, which may compromise airtightness. Choosing heat sealable cellophane improves durability and shelf life, making it ideal for sensitive or perishable goods.

Table of Comparison

| Feature | Heat Sealable Cellophane | Non-Sealable Cellophane |

|---|---|---|

| Material | Cellophane coated with heat-activated adhesive | Standard cellophane film |

| Sealing Ability | Can be heat sealed for airtight packaging | Cannot be sealed by heat |

| Moisture Barrier | Enhanced moisture resistance due to sealing | Basic moisture resistance, no sealing |

| Typical Uses | Food packaging, gift wraps requiring airtight seal | Decorative wrapping, simple protective layer |

| Durability | Stronger when sealed; protects contents better | Less protective; prone to tears without sealing |

| Cost | Higher due to heat-seal coating | Lower cost, standard cellophane |

Understanding Cellophane: An Overview

Heat sealable cellophane is coated with a polymer layer, enabling airtight, moisture-resistant seals ideal for food packaging and preserving freshness. Non-sealable cellophane lacks this coating, making it more suitable for decorative or protective applications where sealing is not required. Understanding these differences helps select the appropriate cellophane type based on packaging needs and product protection levels.

What is Heat Sealable Cellophane?

Heat sealable cellophane is a type of cellulose film treated to allow the edges to bond securely when exposed to heat, providing airtight and moisture-resistant packaging. This variant enhances product protection by creating a reliable seal, unlike non-sealable cellophane, which lacks this heat-activated bonding property and is typically used for decorative or wrapping purposes. Heat sealable cellophane is widely used in food packaging, pharmaceuticals, and retail to extend shelf life and maintain product freshness.

Defining Non-Sealable Cellophane

Non-sealable cellophane is a cellulose-based film that lacks the ability to bond when heat is applied, making it unsuitable for heat sealing packaging processes. This variant maintains excellent clarity, moisture resistance, and biodegradability but requires alternative sealing methods such as adhesives or mechanical closures. Its non-heat sealable nature limits use in applications demanding airtight or tamper-evident packaging.

Key Composition Differences

Heat sealable cellophane contains a thin polymer coating, typically polyethylene or a similar thermoplastic, which allows the film to be sealed using heat, ensuring airtight packaging. In contrast, non-sealable cellophane lacks this polymer layer, consisting primarily of pure regenerated cellulose, making it breathable but unable to form heat seals. The presence or absence of this polymer coating is the fundamental composition difference that dictates the functional applications and sealing capabilities of cellophane materials.

Heat Sealing Process Explained

Heat sealable cellophane undergoes a coating process that modifies its surface, allowing the film to bond securely when exposed to specific temperatures and pressure during the heat sealing process. This process involves the melting of the coated layer, creating a hermetic seal that enhances product protection and prolongs shelf life. In contrast, non-sealable cellophane lacks this modified surface, making it unsuitable for heat sealing and limiting its use to simple wrapping applications.

Advantages of Heat Sealable Cellophane

Heat sealable cellophane offers superior packaging security by creating airtight seals that prevent contamination and extend product shelf life. Its moisture resistance and ability to maintain freshness make it ideal for food packaging and perishable goods. Compared to non-sealable cellophane, heat sealable variants enhance product presentation while improving ease of use and packaging efficiency.

Uses of Non-Sealable Cellophane

Non-sealable cellophane is primarily used for decorative packaging, gift wrapping, and floral arrangements due to its glossy appearance and breathability. It allows moisture vapor transmission, making it suitable for packaging fresh produce and flowers without causing condensation. This type enhances product presentation while maintaining freshness and visual appeal in retail displays.

Comparative Barrier Properties

Heat sealable cellophane exhibits superior moisture and oxygen barrier properties compared to non-sealable cellophane, enhancing product freshness and shelf life. Non-sealable cellophane lacks the polymer coating that facilitates hermetic sealing, resulting in higher permeability to gases and vapors. The improved barrier properties of heat sealable cellophane make it more suitable for food packaging applications requiring extended preservation and protection from external contaminants.

Environmental Impact and Sustainability

Heat sealable cellophane offers enhanced sustainability compared to non-sealable varieties due to its ability to create airtight packaging, reducing food wastage and extending shelf life. Both types are biodegradable and derived from renewable cellulose sources, yet heat sealable cellophane often incorporates eco-friendly coatings that improve recyclability without compromising compostability. Non-sealable cellophane requires alternative closure methods that may increase plastic use, negatively impacting its overall environmental footprint.

Choosing the Right Cellophane for Your Application

Heat sealable cellophane offers superior moisture resistance and airtight packaging, ideal for food products and perishables requiring extended shelf life. Non-sealable cellophane, while maintaining excellent biodegradability and clarity, suits applications where sealing is unnecessary, such as gift wrapping or decorative purposes. Selecting the right cellophane depends on balancing packaging needs for durability, product protection, and environmental impact.

Heat Sealable Cellophane vs Non-Sealable Cellophane Infographic

materialdif.com

materialdif.com