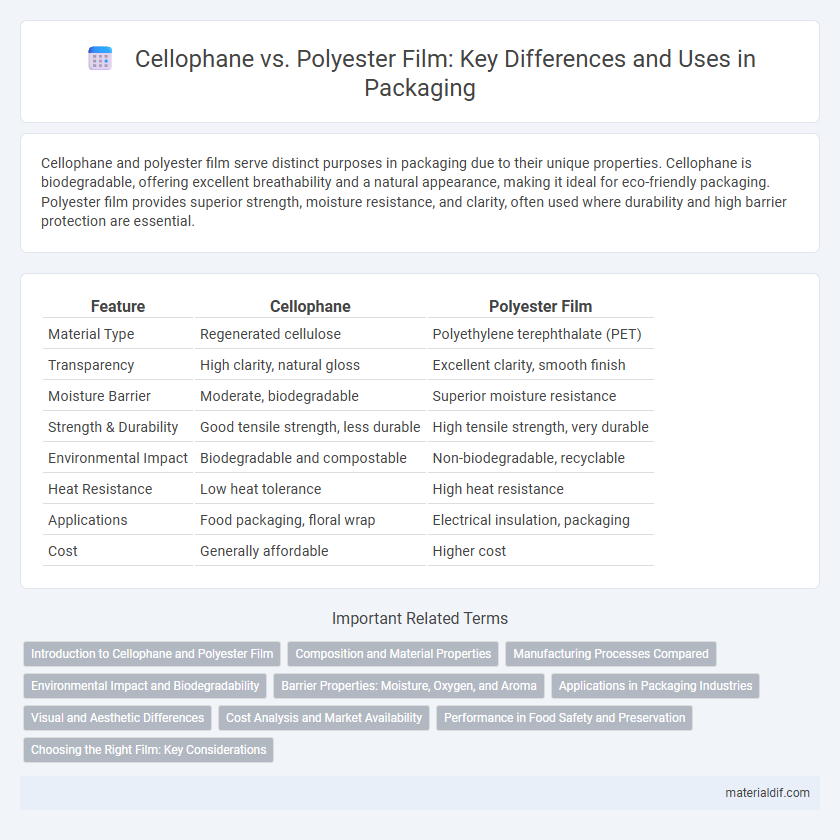

Cellophane and polyester film serve distinct purposes in packaging due to their unique properties. Cellophane is biodegradable, offering excellent breathability and a natural appearance, making it ideal for eco-friendly packaging. Polyester film provides superior strength, moisture resistance, and clarity, often used where durability and high barrier protection are essential.

Table of Comparison

| Feature | Cellophane | Polyester Film |

|---|---|---|

| Material Type | Regenerated cellulose | Polyethylene terephthalate (PET) |

| Transparency | High clarity, natural gloss | Excellent clarity, smooth finish |

| Moisture Barrier | Moderate, biodegradable | Superior moisture resistance |

| Strength & Durability | Good tensile strength, less durable | High tensile strength, very durable |

| Environmental Impact | Biodegradable and compostable | Non-biodegradable, recyclable |

| Heat Resistance | Low heat tolerance | High heat resistance |

| Applications | Food packaging, floral wrap | Electrical insulation, packaging |

| Cost | Generally affordable | Higher cost |

Introduction to Cellophane and Polyester Film

Cellophane is a thin, transparent film made from regenerated cellulose, known for its biodegradability and excellent breathability, commonly used in food packaging to maintain freshness. Polyester film, primarily made from polyethylene terephthalate (PET), offers superior strength, durability, and moisture resistance, making it ideal for long-term packaging and industrial applications. Both materials serve distinct functions in packaging, with cellophane favored for environmentally friendly uses and polyester film preferred for high-performance requirements.

Composition and Material Properties

Cellophane is made from cellulose derived from wood pulp, giving it a biodegradable and breathable quality, whereas polyester film, typically made from polyethylene terephthalate (PET), is synthetic and non-biodegradable. Cellophane exhibits excellent moisture permeability and clarity but lower tensile strength compared to polyester film, which offers superior durability, chemical resistance, and dimensional stability. The hydrophilic nature of cellophane contrasts with the hydrophobic properties of polyester film, influencing their applications in packaging and insulation.

Manufacturing Processes Compared

Cellophane is produced through the viscose process, where cellulose from wood pulp is treated with alkali and carbon disulfide, then regenerated into thin transparent sheets, emphasizing biodegradability and natural origin. Polyester film, typically polyethylene terephthalate (PET), is created by melt extrusion and biaxial orientation, resulting in a durable, moisture-resistant synthetically engineered material. The manufacturing difference highlights cellophane's renewable raw materials and biodegradability, contrasting with polyester film's synthetic production and enhanced mechanical strength.

Environmental Impact and Biodegradability

Cellophane, derived from cellulose, is biodegradable and compostable, making it an eco-friendly alternative to polyester film, which is petroleum-based and non-biodegradable. Unlike polyester, which contributes to microplastic pollution and requires significant fossil fuel resources, cellophane breaks down naturally in soil and marine environments within weeks to months. This biodegradability positions cellophane as a sustainable packaging choice aligned with circular economy principles, reducing long-term environmental impact.

Barrier Properties: Moisture, Oxygen, and Aroma

Cellophane offers superior moisture barrier properties due to its natural cellulose composition, making it highly effective at preventing water vapor transmission. In contrast, polyester film excels in oxygen barrier resistance, providing excellent protection against oxidation and extending product shelf life. Both materials vary in aroma retention, with polyester film generally demonstrating better aroma barrier capabilities, reducing flavor and odor loss in packaged goods.

Applications in Packaging Industries

Cellophane offers superior biodegradability and breathability, making it ideal for packaging fresh produce and bakery items where moisture control and environmental impact are critical. Polyester film excels in durability, clarity, and heat resistance, suited for packaging that requires strong barrier protection for items like electronics and pharmaceuticals. Both materials serve distinct roles in packaging industries, with cellophane favored for eco-friendly and breathable applications, while polyester film supports high-strength, long-lasting packaging solutions.

Visual and Aesthetic Differences

Cellophane offers a natural, glossy appearance with high transparency and a slight crisp texture, making it ideal for packaging that emphasizes organic or retro aesthetics. Polyester film provides superior clarity with a smooth, polished finish and enhanced durability, often used in applications requiring a sleek, modern look. The choice between cellophane and polyester film impacts the visual appeal, where cellophane's warmth contrasts with the clean, vibrant sheen of polyester.

Cost Analysis and Market Availability

Cellophane typically incurs higher production costs due to its natural cellulose base and more complex manufacturing process compared to polyester film, which benefits from lower raw material costs and scalable synthetic production. Market availability favors polyester film, widely accessible and cost-efficient for mass production in packaging and industrial applications, while cellophane is often limited to niche markets seeking biodegradable or eco-friendly materials despite its higher price point. Pricing trends show polyester film dominates price-sensitive sectors, whereas cellophane caters to premium segments valuing sustainability and natural origin.

Performance in Food Safety and Preservation

Cellophane outperforms polyester film in food safety by being naturally biodegradable and free from harmful chemicals, ensuring safer packaging for perishable goods. Its superior gas permeability allows better moisture and oxygen exchange, enhancing food preservation and extending shelf life. Polyester film offers greater durability but lacks the breathability essential for maintaining freshness in sensitive food products.

Choosing the Right Film: Key Considerations

Cellophane offers superior biodegradability and natural moisture permeability, making it ideal for eco-friendly packaging and breathable applications, whereas polyester film excels in durability, chemical resistance, and moisture barrier properties. Selecting the right film depends on factors such as environmental impact, required barrier performance, flexibility, and end-use conditions. For packaging that necessitates sustainability and compostability, cellophane is preferable, while polyester film suits long-term protection and high-strength demands.

Cellophane vs Polyester Film Infographic

materialdif.com

materialdif.com