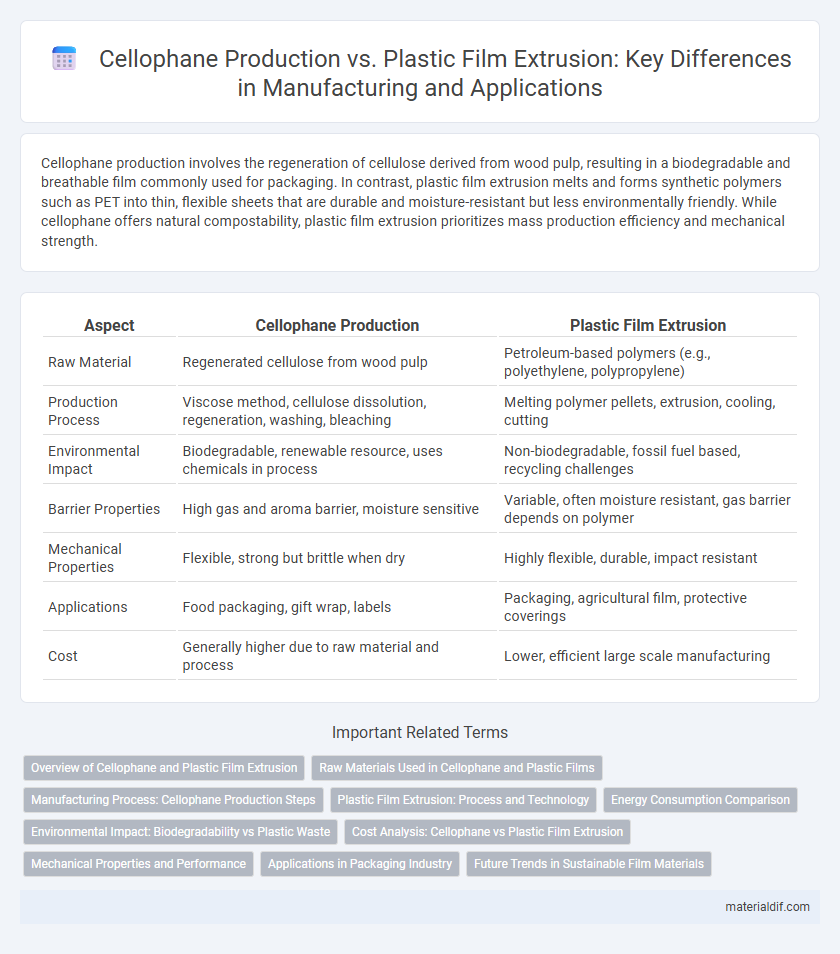

Cellophane production involves the regeneration of cellulose derived from wood pulp, resulting in a biodegradable and breathable film commonly used for packaging. In contrast, plastic film extrusion melts and forms synthetic polymers such as PET into thin, flexible sheets that are durable and moisture-resistant but less environmentally friendly. While cellophane offers natural compostability, plastic film extrusion prioritizes mass production efficiency and mechanical strength.

Table of Comparison

| Aspect | Cellophane Production | Plastic Film Extrusion |

|---|---|---|

| Raw Material | Regenerated cellulose from wood pulp | Petroleum-based polymers (e.g., polyethylene, polypropylene) |

| Production Process | Viscose method, cellulose dissolution, regeneration, washing, bleaching | Melting polymer pellets, extrusion, cooling, cutting |

| Environmental Impact | Biodegradable, renewable resource, uses chemicals in process | Non-biodegradable, fossil fuel based, recycling challenges |

| Barrier Properties | High gas and aroma barrier, moisture sensitive | Variable, often moisture resistant, gas barrier depends on polymer |

| Mechanical Properties | Flexible, strong but brittle when dry | Highly flexible, durable, impact resistant |

| Applications | Food packaging, gift wrap, labels | Packaging, agricultural film, protective coverings |

| Cost | Generally higher due to raw material and process | Lower, efficient large scale manufacturing |

Overview of Cellophane and Plastic Film Extrusion

Cellophane is a thin, transparent film made from regenerated cellulose derived from wood pulp, known for its biodegradability and breathability. Plastic film extrusion involves melting polymer resins like polyethylene or polypropylene and forming continuous films through a die, offering high production speed and versatility. Compared to plastic film extrusion, cellophane production is more environmentally friendly but generally slower and less adaptable to high-speed manufacturing processes.

Raw Materials Used in Cellophane and Plastic Films

Cellophane production primarily uses cellulose derived from wood pulp or cotton fibers, making it a biodegradable and renewable raw material source. In contrast, plastic film extrusion relies on petrochemical-based polymers such as polyethylene, polypropylene, and polyvinyl chloride, which are derived from non-renewable fossil fuels. The natural origin of cellulose in cellophane contributes to its eco-friendly profile, whereas plastic films often present environmental challenges due to their synthetic composition.

Manufacturing Process: Cellophane Production Steps

Cellophane production involves dissolving cellulose from wood pulp or cotton into alkali and carbon disulfide to form viscose, which is then extruded through a slit into an acid bath to regenerate the cellulose film. This process requires precise washing, bleaching, and coating stages to enhance the film's clarity, strength, and moisture resistance. Unlike plastic film extrusion that melts polymers such as polyethylene, cellophane's manufacturing relies on chemical regeneration, making it biodegradable and derived from renewable resources.

Plastic Film Extrusion: Process and Technology

Plastic film extrusion involves melting polymer resins such as polyethylene or polypropylene and forcing the molten material through a die to form thin films, which are then rapidly cooled and solidified. This continuous process allows precise control over film thickness, width, and properties, enabling diverse applications from packaging to agricultural covers. Advanced extrusion technologies incorporate blown or cast film methods, optimizing mechanical strength, clarity, and barrier properties for enhanced performance compared to traditional cellophane production.

Energy Consumption Comparison

Cellophane production consumes significantly less energy compared to traditional plastic film extrusion, primarily due to its renewable cellulose base and less intensive chemical processing. The energy required for cellophane manufacturing ranges between 15-25 MJ/kg, whereas plastic film extrusion often exceeds 40 MJ/kg, highlighting its higher fossil fuel dependency. Lower energy consumption in cellophane production contributes to reduced carbon emissions and a smaller environmental footprint.

Environmental Impact: Biodegradability vs Plastic Waste

Cellophane production relies on cellulose derived from wood pulp, making it biodegradable and compostable within weeks, which significantly reduces its environmental footprint compared to plastic film extrusion that generates persistent plastic waste. Unlike plastic films, which often contribute to long-term landfill accumulation and microplastic pollution due to their resistance to degradation, cellophane naturally decomposes, minimizing soil and marine contamination. The shift toward cellophane supports circular economy goals by lowering reliance on fossil fuels and enhancing waste management through sustainable end-of-life options.

Cost Analysis: Cellophane vs Plastic Film Extrusion

Cellophane production involves a more labor-intensive process with higher raw material costs due to the use of cellulose derived from wood pulp, resulting in increased overall expenses compared to plastic film extrusion. Plastic film extrusion benefits from economies of scale and lower-cost petrochemical feedstocks like polyethylene or polypropylene, leading to reduced production costs and faster manufacturing cycles. Cost analysis reveals that plastic film extrusion is generally more economical for high-volume packaging applications, while cellophane remains preferred for biodegradable and moisture-resistant properties despite its higher price point.

Mechanical Properties and Performance

Cellophane exhibits superior tensile strength and biodegradability compared to conventional plastic film extrusion materials such as polyethylene and polypropylene, making it more environmentally sustainable. Its high gas and moisture permeability allows for enhanced breathability in packaging applications, whereas plastic films often provide stronger barrier properties but contribute significantly to plastic pollution. The inherent rigidity of cellophane limits its flexibility and tear resistance relative to extruded plastic films, which are engineered for higher durability and impact resistance in various industrial uses.

Applications in Packaging Industry

Cellophane, derived from cellulose, offers superior breathability and biodegradability compared to plastic film extrusion, making it ideal for packaging fresh produce, baked goods, and confectionery where moisture control is critical. Plastic films, produced through extrusion of synthetic polymers like polyethylene or polypropylene, provide higher durability and moisture barriers optimal for long-term food storage and industrial packaging. The packaging industry increasingly prefers cellophane for eco-friendly solutions, while plastic films dominate high-strength packaging applications due to cost-effectiveness and versatility.

Future Trends in Sustainable Film Materials

Cellophane production utilizes regenerated cellulose derived from renewable wood pulp, offering superior biodegradability compared to conventional plastic film extrusion, which relies heavily on petroleum-based polymers. Future trends emphasize developing bio-based and compostable films with enhanced barrier properties, driven by increasing environmental regulations and consumer demand for sustainable packaging. Innovations in cellophane technology focus on reducing chemical usage during processing and improving recyclability, positioning it as a viable alternative to traditional plastic films in eco-friendly applications.

Cellophane production vs Plastic film extrusion Infographic

materialdif.com

materialdif.com