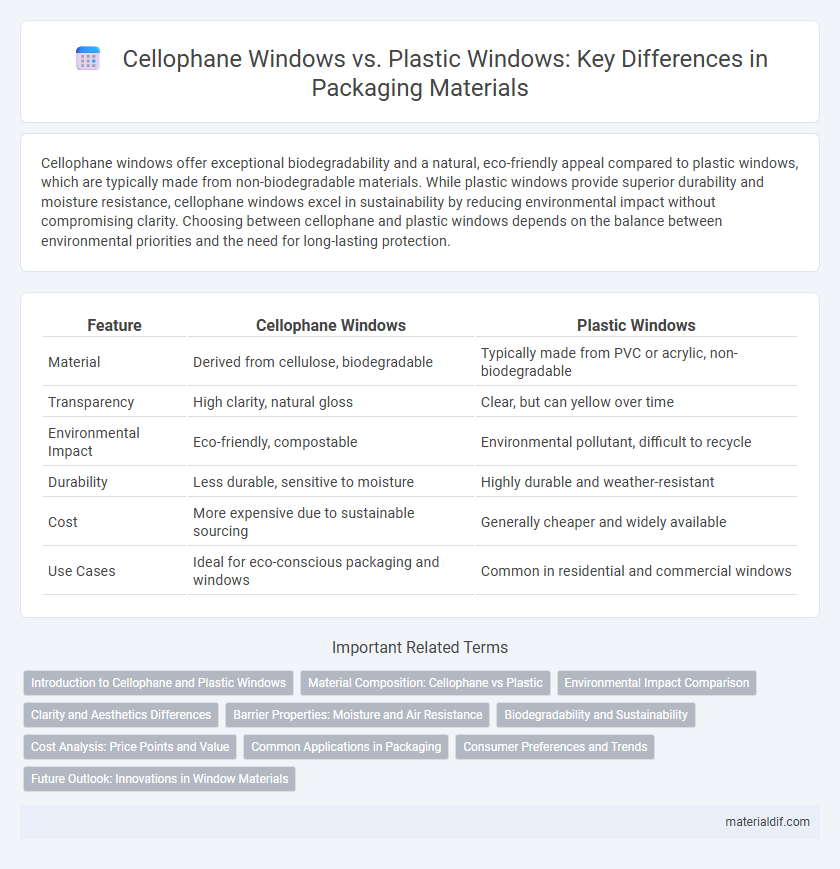

Cellophane windows offer exceptional biodegradability and a natural, eco-friendly appeal compared to plastic windows, which are typically made from non-biodegradable materials. While plastic windows provide superior durability and moisture resistance, cellophane windows excel in sustainability by reducing environmental impact without compromising clarity. Choosing between cellophane and plastic windows depends on the balance between environmental priorities and the need for long-lasting protection.

Table of Comparison

| Feature | Cellophane Windows | Plastic Windows |

|---|---|---|

| Material | Derived from cellulose, biodegradable | Typically made from PVC or acrylic, non-biodegradable |

| Transparency | High clarity, natural gloss | Clear, but can yellow over time |

| Environmental Impact | Eco-friendly, compostable | Environmental pollutant, difficult to recycle |

| Durability | Less durable, sensitive to moisture | Highly durable and weather-resistant |

| Cost | More expensive due to sustainable sourcing | Generally cheaper and widely available |

| Use Cases | Ideal for eco-conscious packaging and windows | Common in residential and commercial windows |

Introduction to Cellophane and Plastic Windows

Cellophane windows are made from regenerated cellulose film, offering biodegradability and excellent clarity, making them an eco-friendly alternative to traditional plastic windows. Plastic windows, typically crafted from polyethylene or polypropylene, provide durability and water resistance but contribute to environmental pollution due to their non-biodegradable nature. Understanding the material composition and environmental impact is essential when choosing between cellophane and plastic windows for packaging applications.

Material Composition: Cellophane vs Plastic

Cellophane windows are made from regenerated cellulose derived from wood pulp, making them biodegradable and environmentally friendly. Plastic windows, typically composed of polyethylene or polyvinyl chloride (PVC), are synthetic polymers that offer higher durability but contribute to plastic pollution. The natural origin of cellophane provides better breathability and compostability compared to the long-lasting synthetic nature of plastic window films.

Environmental Impact Comparison

Cellophane windows are biodegradable and derived from cellulose, making them an eco-friendly alternative to plastic windows, which are typically made from non-biodegradable petroleum-based materials. Unlike plastic windows that contribute to long-term pollution and microplastic accumulation, cellophane decomposes naturally without releasing harmful toxins into the environment. The production of cellophane also often consumes less energy and emits fewer greenhouse gases compared to the manufacturing processes for plastic windows.

Clarity and Aesthetics Differences

Cellophane windows offer superior clarity with their natural, transparent film that resists yellowing and maintains a crisp, clear appearance over time compared to plastic windows. The aesthetic appeal of cellophane windows is enhanced by their smooth, glossy surface that mimics glass, creating a premium, high-quality look. Plastic windows often cloud or scratch easily, resulting in a duller, less visually appealing finish that can detract from the overall packaging design.

Barrier Properties: Moisture and Air Resistance

Cellophane windows offer superior moisture vapor resistance compared to traditional plastic windows, effectively reducing condensation and preserving product freshness. Their natural cellulose composition provides excellent air permeability control, enhancing breathability without sacrificing barrier integrity. In contrast, plastic windows typically exhibit lower moisture resistance and can create airtight seals that may trap humidity, impacting overall package quality.

Biodegradability and Sustainability

Cellophane windows offer superior biodegradability compared to plastic windows, as they are made from cellulose derived from wood pulp, enabling natural decomposition within weeks under composting conditions. This renewable cellulose base supports sustainability by reducing reliance on petroleum-based plastics that persist in landfills for hundreds of years and contribute to microplastic pollution. Brands prioritizing eco-friendly packaging often choose cellophane to minimize environmental impact and promote circular economy practices in product design.

Cost Analysis: Price Points and Value

Cellophane windows tend to be more affordable due to their lightweight and biodegradable material, offering cost-effective solutions for short-term or eco-friendly applications. Plastic windows, such as those made from PVC or polycarbonate, generally have higher upfront costs but provide greater durability, insulation, and long-term value. When assessing price points, cellophane windows minimize initial expenses, while plastic windows deliver superior performance and potential energy savings, influencing overall cost-effectiveness based on project duration and environmental priorities.

Common Applications in Packaging

Cellophane windows are widely used in food packaging, offering biodegradability and excellent breathability that preserves freshness, making them ideal for bakery goods, confectionery, and dried fruits. Plastic windows, often made from materials like PVC or PET, provide superior durability and moisture resistance, commonly applied in flexible packaging for snacks, frozen foods, and ready-to-eat meals. Both materials enhance product visibility but differ in environmental impact and barrier properties, influencing their selection based on packaging requirements.

Consumer Preferences and Trends

Consumers show a growing preference for plastic windows over cellophane windows due to enhanced durability, improved insulation, and better weather resistance. Plastic windows, often made from PVC or vinyl, offer greater energy efficiency, contributing to reduced heating and cooling costs. Trends indicate increasing demand for eco-friendly plastic window options that provide longer lifespan and superior performance compared to traditional cellophane alternatives.

Future Outlook: Innovations in Window Materials

Cellophane windows are gaining attention due to their biodegradable properties and sustainable sourcing, offering a greener alternative to traditional plastic windows made from PVC or polyethylene. Emerging innovations in window materials prioritize enhanced transparency, durability, and environmental impact reduction, positioning cellophane as a promising candidate for eco-friendly packaging and construction. Future research focuses on improving moisture resistance and mechanical strength of cellophane to compete effectively with versatile plastic windows in various applications.

Cellophane Windows vs Plastic Windows Infographic

materialdif.com

materialdif.com