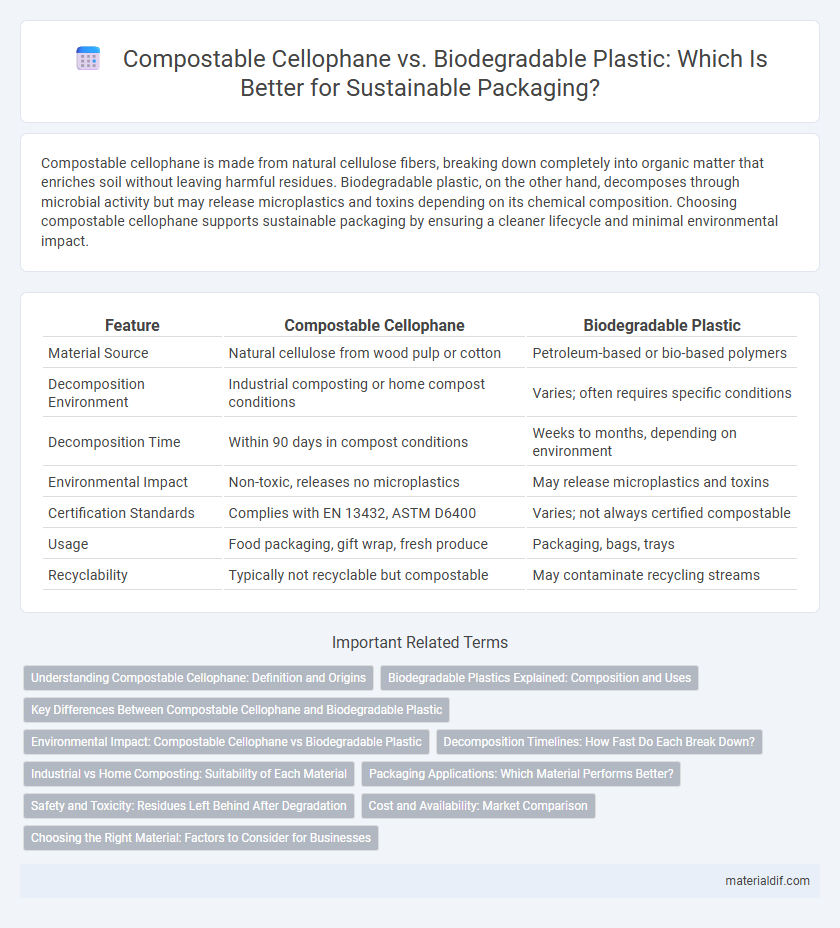

Compostable cellophane is made from natural cellulose fibers, breaking down completely into organic matter that enriches soil without leaving harmful residues. Biodegradable plastic, on the other hand, decomposes through microbial activity but may release microplastics and toxins depending on its chemical composition. Choosing compostable cellophane supports sustainable packaging by ensuring a cleaner lifecycle and minimal environmental impact.

Table of Comparison

| Feature | Compostable Cellophane | Biodegradable Plastic |

|---|---|---|

| Material Source | Natural cellulose from wood pulp or cotton | Petroleum-based or bio-based polymers |

| Decomposition Environment | Industrial composting or home compost conditions | Varies; often requires specific conditions |

| Decomposition Time | Within 90 days in compost conditions | Weeks to months, depending on environment |

| Environmental Impact | Non-toxic, releases no microplastics | May release microplastics and toxins |

| Certification Standards | Complies with EN 13432, ASTM D6400 | Varies; not always certified compostable |

| Usage | Food packaging, gift wrap, fresh produce | Packaging, bags, trays |

| Recyclability | Typically not recyclable but compostable | May contaminate recycling streams |

Understanding Compostable Cellophane: Definition and Origins

Compostable cellophane is a transparent film made from natural cellulose derived primarily from wood pulp, designed to break down completely into non-toxic components within a composting environment. Unlike biodegradable plastics that may fragment into microplastics and persist in ecosystems, compostable cellophane undergoes microbial decomposition, returning nutrients to the soil without harmful residues. Originating from renewable resources, compostable cellophane offers an eco-friendly alternative to petroleum-based plastics, aligning with sustainable packaging goals.

Biodegradable Plastics Explained: Composition and Uses

Biodegradable plastics are composed of materials such as polylactic acid (PLA) derived from renewable biomass like corn starch or sugarcane, enabling them to break down naturally under specific environmental conditions. These plastics are commonly used in packaging, agricultural films, and disposable items due to their reduced environmental impact compared to conventional plastics. Unlike compostable cellophane, biodegradable plastics may not always fully decompose into non-toxic components without industrial composting facilities.

Key Differences Between Compostable Cellophane and Biodegradable Plastic

Compostable cellophane is made from natural cellulose fibers, allowing it to break down fully in composting environments within 60 to 90 days, leaving no toxic residue. Biodegradable plastics, derived from petroleum or plant-based sources, degrade through microbial activity but often require specific conditions and longer timespans, sometimes producing microplastics. The key difference lies in compostable cellophane's ability to convert into nutrient-rich compost, whereas biodegradable plastics may only partially decompose, impacting environmental sustainability.

Environmental Impact: Compostable Cellophane vs Biodegradable Plastic

Compostable cellophane, derived from cellulose, breaks down naturally into non-toxic components within a short time frame, minimizing soil and water contamination. Biodegradable plastics, often petroleum-based, may fragment into microplastics and release harmful substances, posing risks to ecosystems. The environmental impact of compostable cellophane is significantly lower due to its renewable origin and complete biodegradability compared to many biodegradable plastics.

Decomposition Timelines: How Fast Do Each Break Down?

Compostable cellophane typically decomposes within 4 to 6 weeks under industrial composting conditions, breaking down into non-toxic organic matter that enriches soil. In contrast, biodegradable plastics can take several months to years to decompose fully, depending on environmental factors and the specific polymer composition. The faster decomposition timeline of compostable cellophane makes it a more sustainable option for reducing landfill waste and promoting eco-friendly packaging solutions.

Industrial vs Home Composting: Suitability of Each Material

Compostable cellophane, derived from cellulose, is suitable for both industrial and home composting due to its natural origin and ability to break down without toxic residues. Biodegradable plastics often require industrial composting conditions, such as higher temperatures and controlled humidity, to fully decompose, making them less suitable for home composting environments. Industrial composting facilities provide the optimal environment for biodegradable plastics, whereas compostable cellophane offers greater versatility and environmental benefits across both composting systems.

Packaging Applications: Which Material Performs Better?

Compostable cellophane, made from cellulose derived from wood pulp, offers superior breathability and moisture resistance for packaging fresh produce compared to biodegradable plastics, which often rely on petroleum-based polymers that degrade more slowly. In packaging applications demanding transparency, flexibility, and eco-friendly disposal, compostable cellophane outperforms biodegradable plastic by breaking down fully in industrial composting environments without leaving microplastic residues. This makes compostable cellophane a more sustainable choice for food packaging, aligning with growing industry standards and consumer preferences for renewable materials.

Safety and Toxicity: Residues Left Behind After Degradation

Compostable cellophane, derived from cellulose, breaks down into non-toxic organic matter without leaving harmful residues, ensuring safe soil and water environments. In contrast, biodegradable plastics often degrade into microplastics or toxic substances that can persist in ecosystems, posing risks to wildlife and human health. The safety profile of compostable cellophane makes it a superior choice for sustainable packaging and waste management.

Cost and Availability: Market Comparison

Compostable cellophane generally has higher production costs due to its natural cellulose base, making it more expensive than biodegradable plastics derived from synthetic polymers. Availability of compostable cellophane is often limited to niche markets and specialty suppliers, whereas biodegradable plastics benefit from larger-scale manufacturing and broader distribution networks. Market trends indicate growing demand for compostable cellophane in sustainable packaging, but cost and supply constraints currently favor the more accessible biodegradable plastic alternatives.

Choosing the Right Material: Factors to Consider for Businesses

Compostable cellophane, derived from cellulose, offers a renewable and non-toxic alternative to biodegradable plastics, which often contain synthetic additives that can hinder complete environmental breakdown. Businesses should evaluate factors such as end-of-life disposal methods, packaging requirements, and compatibility with existing recycling systems to ensure sustainable material selection. Considering regulatory compliance, consumer perception, and product shelf life will guide companies in choosing the most eco-friendly and efficient packaging solution.

Compostable Cellophane vs Biodegradable Plastic Infographic

materialdif.com

materialdif.com