Natural cellophane, derived from cellulose, offers excellent biodegradability and breathability, making it an eco-friendly packaging option. Synthetic films, such as polyethylene terephthalate (PET), provide superior durability, moisture resistance, and clarity but lack the same level of environmental sustainability. Choosing between natural cellophane and synthetic films depends on balancing ecological impact with functional performance requirements.

Table of Comparison

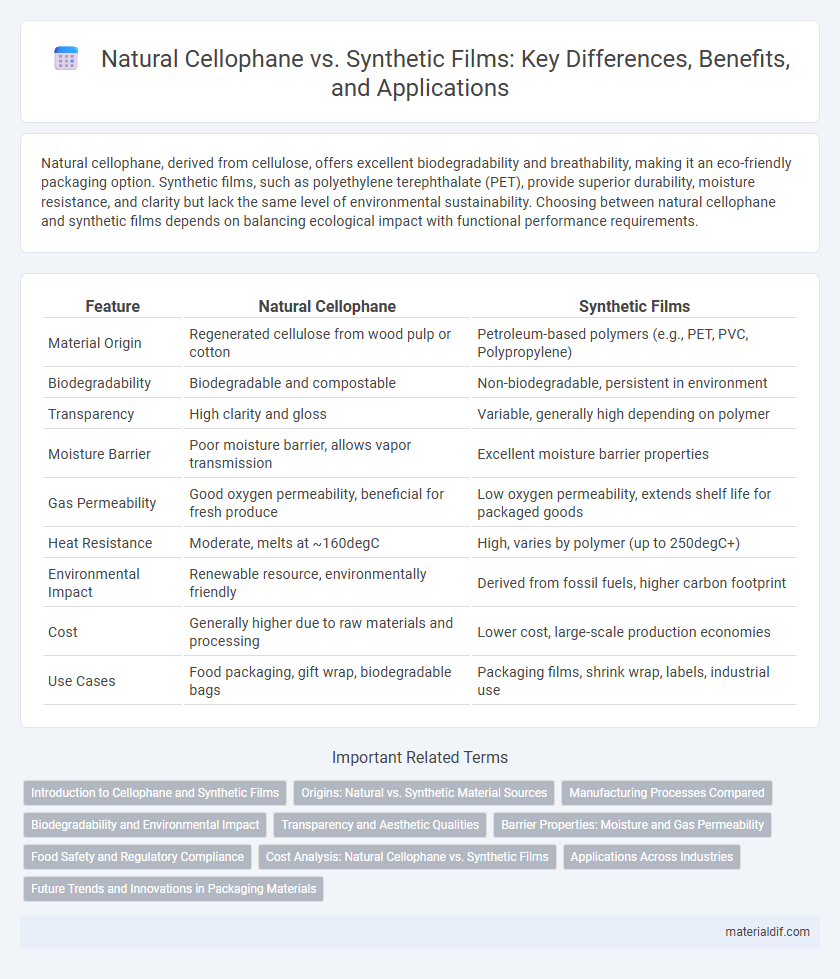

| Feature | Natural Cellophane | Synthetic Films |

|---|---|---|

| Material Origin | Regenerated cellulose from wood pulp or cotton | Petroleum-based polymers (e.g., PET, PVC, Polypropylene) |

| Biodegradability | Biodegradable and compostable | Non-biodegradable, persistent in environment |

| Transparency | High clarity and gloss | Variable, generally high depending on polymer |

| Moisture Barrier | Poor moisture barrier, allows vapor transmission | Excellent moisture barrier properties |

| Gas Permeability | Good oxygen permeability, beneficial for fresh produce | Low oxygen permeability, extends shelf life for packaged goods |

| Heat Resistance | Moderate, melts at ~160degC | High, varies by polymer (up to 250degC+) |

| Environmental Impact | Renewable resource, environmentally friendly | Derived from fossil fuels, higher carbon footprint |

| Cost | Generally higher due to raw materials and processing | Lower cost, large-scale production economies |

| Use Cases | Food packaging, gift wrap, biodegradable bags | Packaging films, shrink wrap, labels, industrial use |

Introduction to Cellophane and Synthetic Films

Cellophane, a transparent film made from regenerated cellulose, serves as a biodegradable and eco-friendly alternative to many synthetic films derived from petroleum-based polymers like polyethylene and polypropylene. Natural cellophane offers excellent breathability and moisture resistance, making it ideal for food packaging, while synthetic films provide superior durability and chemical resistance for industrial applications. Understanding the differences in material composition and environmental impact helps optimize packaging choices for various commercial needs.

Origins: Natural vs. Synthetic Material Sources

Cellophane is derived from natural cellulose, typically sourced from wood pulp, cotton, or hemp, making it a biodegradable and renewable material. Synthetic films like polyethylene or polypropylene originate from petrochemicals obtained through the refining of crude oil, resulting in non-biodegradable plastics. The natural origin of cellophane offers sustainable advantages over synthetic films, which rely on finite fossil fuel resources.

Manufacturing Processes Compared

Natural cellophane is produced through the regeneration of cellulose derived mainly from wood pulp or cotton fibers, involving chemical treatments such as alkali and carbon disulfide to form viscose that solidifies into transparent films. Synthetic films like polyethylene and polypropylene are created via polymerization of petrochemical monomers using extrusion or casting methods, enabling faster production and more consistent properties. The manufacturing of natural cellophane is more resource-intensive and environmentally complex, requiring biodegradability considerations, whereas synthetic films emphasize scalability and functional customization.

Biodegradability and Environmental Impact

Natural cellophane, derived from cellulose fibers, offers superior biodegradability compared to synthetic films like polyethylene and polypropylene, which can persist in the environment for hundreds of years. Its biodegradable properties enable natural cellophane to break down within weeks under composting conditions, significantly reducing landfill waste and microplastic pollution. In contrast, synthetic films contribute to long-term environmental damage due to their resistance to microbial degradation and accumulation in marine and terrestrial ecosystems.

Transparency and Aesthetic Qualities

Natural cellophane offers superior transparency and a glossy finish that enhances the visual appeal of packaged products, making it ideal for showcasing items clearly. Synthetic films often lack the same level of clarity and can exhibit a duller surface, reducing overall aesthetic quality. The biodegradability and natural origin of cellophane also contribute positively to consumer perception, blending sustainability with visual excellence.

Barrier Properties: Moisture and Gas Permeability

Natural cellophane exhibits excellent barrier properties against oxygen and oils, making it ideal for packaging applications requiring moisture resistance. Synthetic films such as polyethylene and polypropylene generally offer superior moisture barrier performance but may lack the oxygen permeability control found in natural cellophane. The balance between moisture and gas permeability in these materials is critical for food preservation and shelf life extension.

Food Safety and Regulatory Compliance

Natural cellophane, derived from cellulose, offers superior biodegradability and is generally recognized as safe (GRAS) by food safety authorities such as the FDA and EFSA, making it a compliant choice for food packaging. Synthetic films, like polyethylene and polypropylene, provide enhanced barrier properties but may raise concerns regarding chemical additives and migration, requiring rigorous regulatory scrutiny under frameworks like the EU's food contact materials legislation. Emphasizing natural cellophane enhances regulatory compliance and reduces food contamination risks, aligning with global trends toward sustainable and safe packaging solutions.

Cost Analysis: Natural Cellophane vs. Synthetic Films

Natural cellophane, derived from cellulose, generally incurs higher production costs due to its biodegradable sourcing and complex manufacturing process, whereas synthetic films like polyethylene and polypropylene benefit from cheaper petroleum-based raw materials and streamlined production methods. Cost analysis reveals that synthetic films dominate the market by offering lower prices and higher scalability, despite environmental concerns associated with their non-biodegradability. However, increasing demand for sustainable packaging solutions is gradually narrowing the cost gap as innovations in natural cellophane production improve efficiency and reduce expenses.

Applications Across Industries

Natural cellophane, derived from cellulose, is widely used in food packaging due to its biodegradability and excellent moisture barrier properties, making it ideal for wrapping fresh produce, baked goods, and confectionery. Synthetic films such as polyethylene and polypropylene dominate industries requiring higher durability, chemical resistance, and flexibility, including pharmaceuticals, electronics, and automotive sectors. The preference for natural cellophane in sustainable packaging contrasts with synthetic films' application in heavy-duty and protective packaging solutions.

Future Trends and Innovations in Packaging Materials

Natural cellophane, derived from cellulose, is gaining momentum as a sustainable alternative to synthetic films due to its biodegradability and compostability. Innovations in bio-based coatings and improved moisture barriers are enhancing natural cellophane's performance, making it suitable for diverse packaging applications. Future trends emphasize integrating nanotechnology and smart sensors within natural films to boost functionality and environmental impact reduction.

Natural Cellophane vs Synthetic Films Infographic

materialdif.com

materialdif.com