Cellophane is a transparent film made from cellulose that offers excellent moisture resistance and breathability, making it ideal for packaging fresh food products. Biodegradable PLA film, derived from renewable plant sources like corn starch, provides a compostable alternative with lower environmental impact but may lack the moisture barrier performance of cellophane. Choosing between cellophane and PLA film depends on balancing packaging durability with ecological benefits.

Table of Comparison

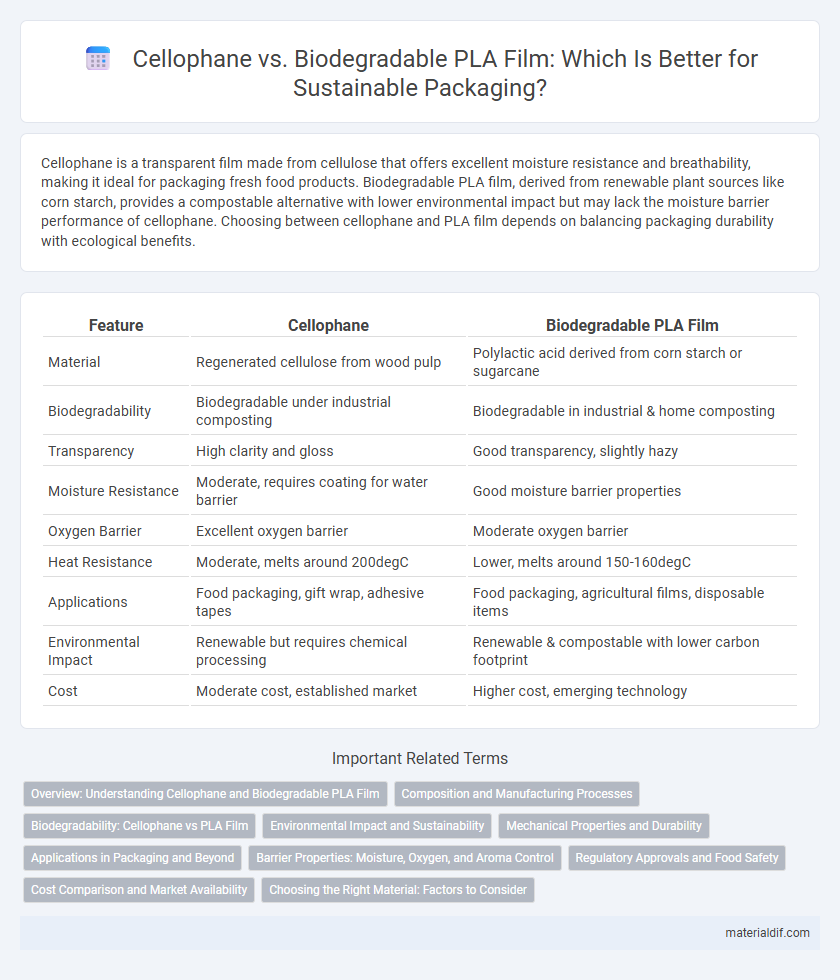

| Feature | Cellophane | Biodegradable PLA Film |

|---|---|---|

| Material | Regenerated cellulose from wood pulp | Polylactic acid derived from corn starch or sugarcane |

| Biodegradability | Biodegradable under industrial composting | Biodegradable in industrial & home composting |

| Transparency | High clarity and gloss | Good transparency, slightly hazy |

| Moisture Resistance | Moderate, requires coating for water barrier | Good moisture barrier properties |

| Oxygen Barrier | Excellent oxygen barrier | Moderate oxygen barrier |

| Heat Resistance | Moderate, melts around 200degC | Lower, melts around 150-160degC |

| Applications | Food packaging, gift wrap, adhesive tapes | Food packaging, agricultural films, disposable items |

| Environmental Impact | Renewable but requires chemical processing | Renewable & compostable with lower carbon footprint |

| Cost | Moderate cost, established market | Higher cost, emerging technology |

Overview: Understanding Cellophane and Biodegradable PLA Film

Cellophane and biodegradable PLA film are both popular packaging materials valued for their eco-friendly properties and transparency. Cellophane is a cellulose-based film derived from wood pulp, prized for its biodegradability and moisture resistance, while PLA (polylactic acid) film is a bioplastic made from fermented plant starch such as corn, offering compostability under industrial conditions. Understanding the differences in their raw materials, decomposition processes, and environmental impacts helps in selecting the appropriate film for sustainable packaging solutions.

Composition and Manufacturing Processes

Cellophane is derived from cellulose, primarily sourced from wood pulp, and undergoes a regeneration process involving steeping, shredding, and dissolution before being cast into thin transparent sheets. Biodegradable PLA film is produced from polylactic acid, a biodegradable thermoplastic made from renewable resources like corn starch or sugarcane, using extrusion and casting methods. The cellulose-based composition of cellophane provides natural biodegradability, whereas PLA films rely on polymerization of lactic acid monomers to achieve compostability under industrial conditions.

Biodegradability: Cellophane vs PLA Film

Cellophane is a biodegradable film derived from cellulose, breaking down naturally within weeks under composting conditions, making it environmentally friendly. PLA (Polylactic Acid) film, produced from fermented plant starch, also biodegrades but often requires industrial composting facilities with controlled temperature and humidity to fully decompose. Compared to PLA film, cellophane typically offers faster and more consistent biodegradability in natural settings due to its natural cellulose structure.

Environmental Impact and Sustainability

Cellophane, derived from regenerated cellulose, is fully biodegradable and compostable, breaking down naturally without releasing harmful microplastics, making it an environmentally friendly film. In contrast, biodegradable PLA (polylactic acid) film, made from corn starch or sugarcane, also decomposes but may require industrial composting facilities to degrade effectively and can produce methane if improperly disposed. The sustainability of cellophane is enhanced by its renewable wood pulp source and low carbon footprint during production, whereas PLA's dependence on agricultural inputs raises concerns about land use and fossil fuel consumption in farming and processing.

Mechanical Properties and Durability

Cellophane exhibits excellent tensile strength and flexibility, making it resistant to tearing and suitable for packaging applications requiring durability. Biodegradable PLA film offers moderate mechanical strength but tends to be more brittle and less flexible compared to cellophane. While cellophane maintains durability under varying humidity conditions, PLA film's mechanical properties can degrade faster in moist environments, limiting its long-term performance.

Applications in Packaging and Beyond

Cellophane offers excellent moisture and aroma barriers, making it ideal for food packaging, while biodegradable PLA film provides compostability and lower environmental impact, appealing to sustainable packaging markets. Both materials are utilized in applications beyond packaging, such as agricultural mulch films and protective wrappings, where their respective properties benefit durability and eco-friendliness. Choosing between cellophane and PLA film depends on specific product requirements, regulatory standards, and consumer demand for sustainability.

Barrier Properties: Moisture, Oxygen, and Aroma Control

Cellophane offers superior moisture barrier properties compared to biodegradable PLA film, making it ideal for packaging products sensitive to humidity. In terms of oxygen permeability, cellophane provides moderate oxygen barrier capabilities, while PLA film exhibits higher oxygen transmission rates which may compromise shelf life. Cellophane also excels in aroma control by limiting flavor and odor migration better than PLA, ensuring preserved product freshness and quality.

Regulatory Approvals and Food Safety

Cellophane, derived from cellulose, has extensive regulatory approvals worldwide for food packaging due to its natural origin and excellent breathability that preserves food quality. Biodegradable PLA film, made from polylactic acid sourced from renewable resources like corn starch, also meets stringent food safety standards set by agencies such as the FDA and EFSA but may face limitations with heat resistance and moisture barrier properties compared to cellophane. Regulatory frameworks increasingly emphasize the environmental benefits of PLA films, promoting their use in sustainable packaging while ensuring compliance with migration limits and food contact safety requirements.

Cost Comparison and Market Availability

Cellophane generally offers a lower production cost due to its established manufacturing process and widespread availability, making it a cost-effective choice for packaging. Biodegradable PLA film, while eco-friendly and compostable, tends to be more expensive because of its raw material costs and less mature supply chain. Market availability favors cellophane with global distribution and multiple suppliers, whereas PLA film availability is more limited and concentrated in regions prioritizing sustainable packaging.

Choosing the Right Material: Factors to Consider

When choosing between cellophane and biodegradable PLA film, consider factors such as environmental impact, durability, and moisture resistance. Cellophane is compostable and offers excellent breathability, making it ideal for food packaging that requires moisture control. PLA film, made from renewable resources, provides superior strength and clarity but may have limited heat resistance and composting infrastructure compatibility.

Cellophane vs Biodegradable PLA Film Infographic

materialdif.com

materialdif.com