Biodegradable cellophane is made from cellulose derived from wood pulp or cotton fibers, breaking down naturally without leaving harmful residues, making it an eco-friendly alternative to traditional plastics. Compostable PLA (polylactic acid) is produced from renewable resources like corn starch and decomposes into organic matter in industrial composting conditions within a specific timeframe. While biodegradable cellophane decomposes in diverse environments including soil and water, compostable PLA requires industrial composting facilities to achieve complete degradation efficiently.

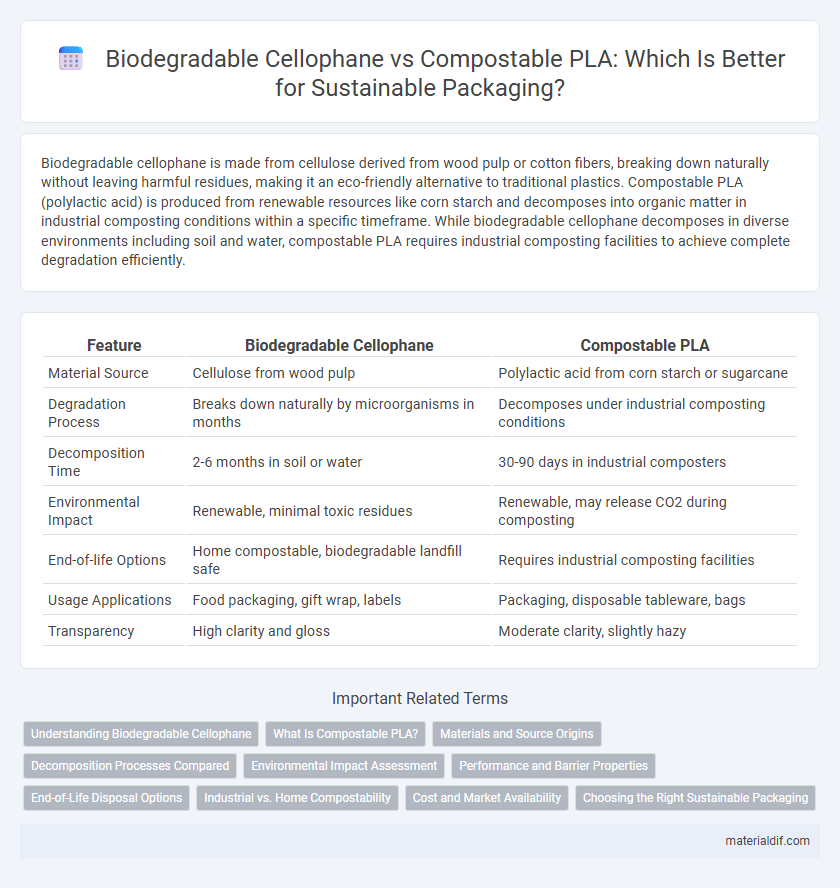

Table of Comparison

| Feature | Biodegradable Cellophane | Compostable PLA |

|---|---|---|

| Material Source | Cellulose from wood pulp | Polylactic acid from corn starch or sugarcane |

| Degradation Process | Breaks down naturally by microorganisms in months | Decomposes under industrial composting conditions |

| Decomposition Time | 2-6 months in soil or water | 30-90 days in industrial composters |

| Environmental Impact | Renewable, minimal toxic residues | Renewable, may release CO2 during composting |

| End-of-life Options | Home compostable, biodegradable landfill safe | Requires industrial composting facilities |

| Usage Applications | Food packaging, gift wrap, labels | Packaging, disposable tableware, bags |

| Transparency | High clarity and gloss | Moderate clarity, slightly hazy |

Understanding Biodegradable Cellophane

Biodegradable cellophane is derived from cellulose, primarily sourced from wood pulp or cotton fibers, and naturally decomposes through microbial activity within weeks to months under environmental conditions. This eco-friendly film breaks down into water, carbon dioxide, and biomass without leaving toxic residues, distinguishing it from petroleum-based plastics. Understanding its composition and degradation process highlights its environmental benefits compared to compostable PLA, which requires industrial composting facilities to fully degrade.

What Is Compostable PLA?

Compostable PLA (polylactic acid) is a bio-based plastic derived from renewable resources like corn starch or sugarcane, designed to break down in industrial composting conditions within 90 to 180 days. Unlike traditional cellophane, which is made from cellulose and is naturally biodegradable, PLA requires specific composting facilities to decompose efficiently. This makes compostable PLA an eco-friendly alternative in packaging that supports sustainable waste management by reducing plastic pollution.

Materials and Source Origins

Biodegradable cellophane is primarily made from regenerated cellulose derived from renewable wood pulp, making it a natural and biodegradable material. Compostable PLA (polylactic acid) is a bioplastic produced from fermented plant starch, commonly corn or sugarcane, which enables industrial composting. While cellophane's cellulose base originates from sustainably managed forests, PLA relies on agricultural crops, influencing production sustainability and end-of-life disposal options.

Decomposition Processes Compared

Biodegradable cellophane decomposes through natural microbial activity, breaking down cellulose into water, carbon dioxide, and biomass without releasing harmful residues. Compostable PLA requires industrial composting conditions, where specific temperatures and humidity levels facilitate its conversion into lactic acid and eventually carbon dioxide and water. The decomposition rate of biodegradable cellophane is generally faster in ambient environments, whereas PLA's breakdown is limited outside controlled composting facilities.

Environmental Impact Assessment

Biodegradable cellophane, derived primarily from cellulose, decomposes naturally without releasing harmful toxins, contributing to reduced plastic pollution and lower carbon emissions during production compared to conventional plastics. Compostable PLA (polylactic acid), sourced from renewable plant starches, breaks down effectively in industrial composting facilities but may persist longer in natural environments, sometimes requiring specific conditions to decompose fully. Environmental impact assessments reveal that while both materials offer advantages over petrochemical plastics, biodegradable cellophane generally has a smaller ecological footprint due to its natural origins and broader degradation capabilities in diverse environments.

Performance and Barrier Properties

Biodegradable cellophane exhibits superior oxygen and aroma barrier properties compared to compostable PLA, making it highly effective for packaging applications that require extended product freshness. While PLA offers excellent compostability and structural versatility, its moisture barrier performance is generally lower, which can limit its use with high-moisture products. The mechanical strength and thermal stability of biodegradable cellophane further enhance its performance in diverse packaging environments where both sustainability and functionality are critical.

End-of-Life Disposal Options

Biodegradable cellophane breaks down naturally through microbial activity, offering a sustainable end-of-life disposal option that reduces environmental impact without requiring industrial processing. Compostable PLA (polylactic acid) demands specific industrial composting conditions, such as controlled temperature and humidity, to fully decompose within a set timeframe. Choosing between biodegradable cellophane and compostable PLA depends on local waste management infrastructure and the availability of appropriate disposal facilities.

Industrial vs. Home Compostability

Biodegradable cellophane, derived from cellulose, breaks down efficiently in industrial composting facilities due to the controlled temperature and humidity conditions required for its decomposition. Compostable PLA (polylactic acid), while also biodegradable, often requires industrial composting to break down fully and may not degrade effectively in home compost environments due to lower and less consistent temperatures. Industrial compostability ensures both materials decompose rapidly, but home compostability varies significantly, with biodegradable cellophane generally exhibiting better breakdown rates in typical home compost setups compared to PLA.

Cost and Market Availability

Biodegradable cellophane, derived from cellulose, generally offers competitive pricing due to its established production processes and widespread market availability across packaging industries. Compostable PLA, made from renewable resources like corn starch, often comes with higher costs linked to complex manufacturing and limited supply chains, restricting its accessibility in broader markets. Cost efficiency and ease of procurement make biodegradable cellophane a more prevalent choice for eco-friendly packaging solutions compared to compostable PLA.

Choosing the Right Sustainable Packaging

Biodegradable cellophane, made from cellulose, decomposes naturally without leaving harmful residues, making it an eco-friendly choice for packaging that requires clear visibility and moisture resistance. Compostable PLA (polylactic acid), derived from renewable resources like corn starch, breaks down in industrial composting facilities, offering a sustainable alternative that supports circular waste management. Selecting the right sustainable packaging depends on factors such as decomposition environment, product protection needs, and end-of-life processing infrastructure.

Biodegradable Cellophane vs Compostable PLA Infographic

materialdif.com

materialdif.com