Cellophane is a biodegradable and transparent packaging material made from cellulose, offering an eco-friendly alternative to PVC (Polyvinyl Chloride), which is a synthetic plastic known for its durability but environmental persistence. Unlike PVC, which can release harmful chemicals during production and disposal, cellophane decomposes naturally without leaving toxic residues, making it ideal for sustainable packaging solutions. Cellophane's breathability and compostability contrast with PVC's impermeability and resistance to decay, highlighting cellophane's advantages for environmentally conscious consumers.

Table of Comparison

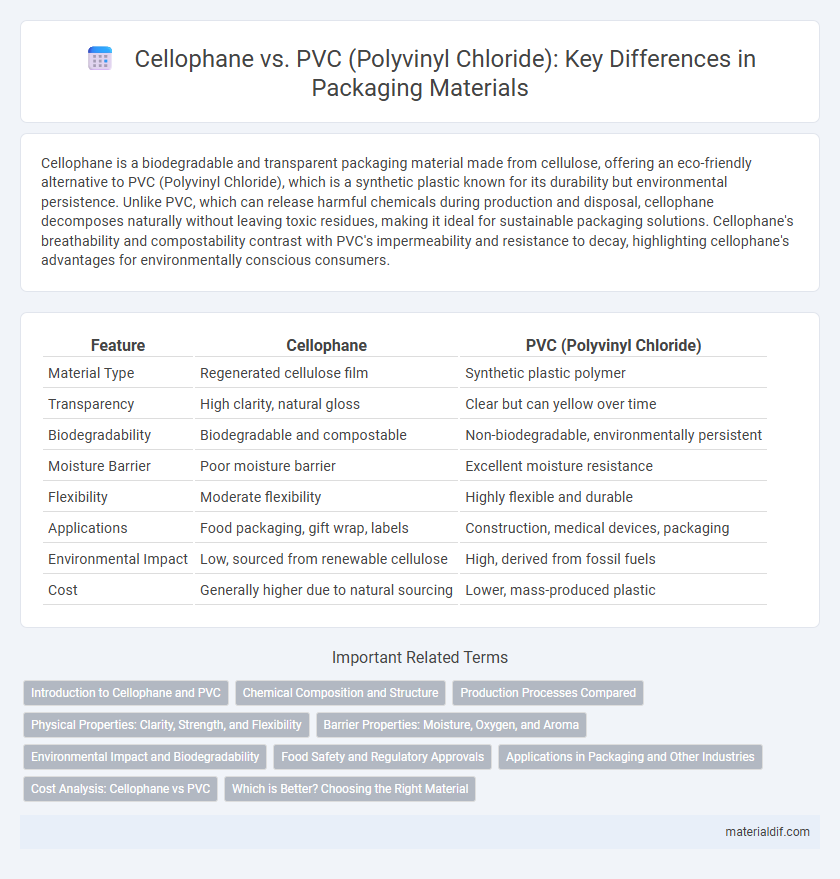

| Feature | Cellophane | PVC (Polyvinyl Chloride) |

|---|---|---|

| Material Type | Regenerated cellulose film | Synthetic plastic polymer |

| Transparency | High clarity, natural gloss | Clear but can yellow over time |

| Biodegradability | Biodegradable and compostable | Non-biodegradable, environmentally persistent |

| Moisture Barrier | Poor moisture barrier | Excellent moisture resistance |

| Flexibility | Moderate flexibility | Highly flexible and durable |

| Applications | Food packaging, gift wrap, labels | Construction, medical devices, packaging |

| Environmental Impact | Low, sourced from renewable cellulose | High, derived from fossil fuels |

| Cost | Generally higher due to natural sourcing | Lower, mass-produced plastic |

Introduction to Cellophane and PVC

Cellophane is a transparent, biodegradable film made from regenerated cellulose derived from wood pulp or cotton fibers, widely used for food packaging due to its breathability and eco-friendly properties. PVC (Polyvinyl Chloride) is a synthetic plastic polymer known for its durability, waterproofing, and chemical resistance, commonly employed in packaging, construction, and medical applications. While Cellophane offers compostability and natural origin benefits, PVC provides superior mechanical strength and moisture barrier capabilities.

Chemical Composition and Structure

Cellophane is a thin, transparent film made from regenerated cellulose derived from wood pulp, characterized by a biodegradable, cellulose polymer structure. PVC (Polyvinyl Chloride) is a synthetic plastic polymer consisting of repeating vinyl chloride monomers with a chlorinated polymer backbone, rendering it non-biodegradable. The natural cellulose matrix of cellophane offers breathability and environmental friendliness, while PVC's rigid, chlorine-infused structure provides durability and chemical resistance but presents environmental disposal challenges.

Production Processes Compared

Cellophane is produced from regenerated cellulose, involving the dissolution of purified cellulose fibers followed by extrusion and chemical regeneration into thin transparent films, making it biodegradable and eco-friendly. PVC production relies on polymerizing vinyl chloride monomers through suspension or emulsion polymerization, resulting in a synthetic plastic with high durability but lower environmental compatibility. The contrast in manufacturing highlights cellophane's natural cellulose base versus PVC's petroleum-derived composition, influencing their respective sustainability profiles.

Physical Properties: Clarity, Strength, and Flexibility

Cellophane offers superior clarity compared to PVC, providing a clearer and more transparent appearance ideal for packaging that showcases contents vividly. While PVC boasts higher strength and impact resistance, cellophane exhibits greater flexibility and breathability, making it suitable for wrapping products that require moisture control. The choice between cellophane and PVC depends on specific needs for transparency, durability, and flexibility in packaging applications.

Barrier Properties: Moisture, Oxygen, and Aroma

Cellophane exhibits superior moisture barrier properties compared to PVC, effectively reducing water vapor transmission rates and maintaining product freshness in packaging applications. Oxygen permeability in cellophane is lower than in PVC, which enhances shelf life by limiting oxidation processes critical for sensitive goods. While PVC provides reasonable aroma barrier performance, cellophane's natural cellulose structure offers enhanced aroma retention, protecting volatile compounds and preserving flavor integrity.

Environmental Impact and Biodegradability

Cellophane is a biodegradable, cellulose-based film derived from natural sources like wood pulp, making it environmentally friendly and compostable within weeks under industrial conditions. In contrast, PVC (Polyvinyl Chloride) is a synthetic plastic polymer that is non-biodegradable, persisting in the environment for decades and releasing toxic chemicals such as dioxins during production and disposal. The renewable origin and biodegradability of cellophane significantly reduce its ecological footprint compared to the persistent pollution and hazardous impact associated with PVC.

Food Safety and Regulatory Approvals

Cellophane is a biodegradable, breathable film made from cellulose, widely recognized for its excellent food safety profile and compliance with global regulatory standards such as FDA and EFSA approvals. In contrast, PVC (Polyvinyl Chloride) contains plasticizers and additives that may leach into food, raising concerns over toxicity and stricter regulations in food packaging applications. Cellophane's natural origin and minimal chemical treatment support safer direct food contact, making it a preferred choice in eco-conscious and health-sensitive markets.

Applications in Packaging and Other Industries

Cellophane offers superior biodegradability compared to PVC, making it a preferred choice in eco-friendly packaging applications such as food wraps and gift wraps where sustainability is critical. PVC provides greater moisture resistance and durability, favoring its use in packaging for electronics, medical supplies, and heavy-duty industrial products. In industries beyond packaging, cellophane is utilized in arts and crafts for decorative purposes, while PVC dominates in construction, automotive parts, and signage due to its robustness and versatility.

Cost Analysis: Cellophane vs PVC

Cellophane generally offers a lower cost option compared to PVC (Polyvinyl Chloride) due to its biodegradable nature and simpler manufacturing process. PVC often incurs higher expenses related to its production, chemical additives, and environmental compliance measures. Businesses weighing packaging materials find cellophane more cost-effective for sustainable applications, while PVC remains pricier but valued for its durability and water resistance.

Which is Better? Choosing the Right Material

Cellophane offers superior biodegradability and breathability compared to PVC, making it a more environmentally friendly packaging option for food items. PVC provides excellent durability, water resistance, and clarity, suitable for long-term storage and protection against moisture. Choosing between cellophane and PVC depends on the application's sustainability goals and performance requirements, with cellophane favored for eco-conscious choices and PVC for robust, moisture-resistant packaging.

Cellophane vs PVC (Polyvinyl Chloride) Infographic

materialdif.com

materialdif.com