Cellophane sheeting offers superior biodegradability compared to acetate sheeting, making it an eco-friendly choice for packaging and crafts. While acetate sheeting provides greater durability and resistance to moisture, cellophane excels in clarity and flexibility, ideal for decorative wrapping and food packaging. Selecting between them depends on the balance of environmental impact and material performance required for your specific application.

Table of Comparison

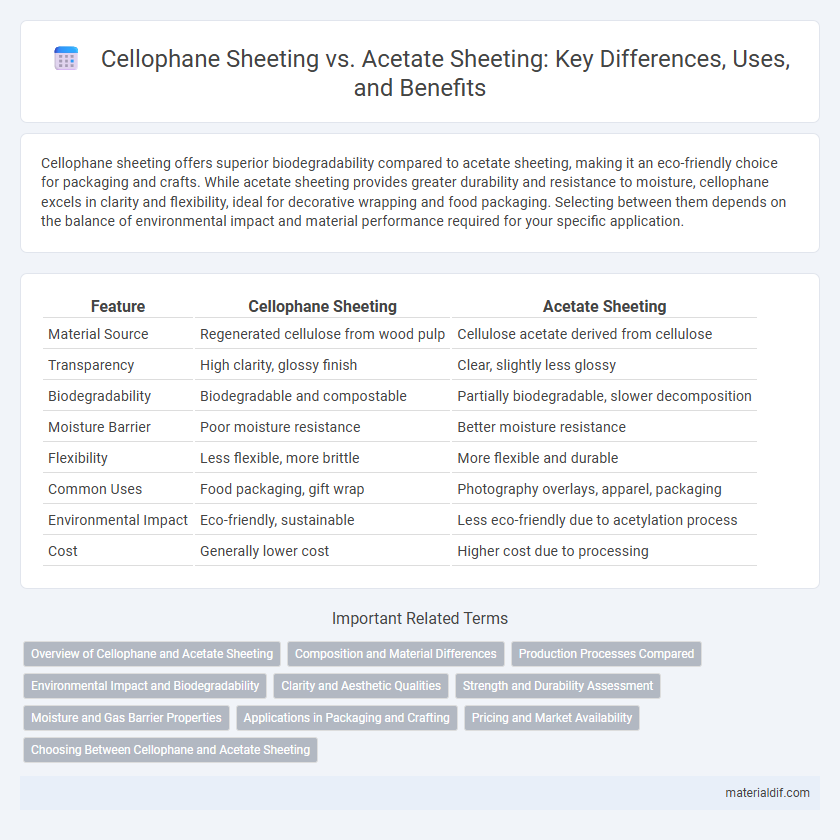

| Feature | Cellophane Sheeting | Acetate Sheeting |

|---|---|---|

| Material Source | Regenerated cellulose from wood pulp | Cellulose acetate derived from cellulose |

| Transparency | High clarity, glossy finish | Clear, slightly less glossy |

| Biodegradability | Biodegradable and compostable | Partially biodegradable, slower decomposition |

| Moisture Barrier | Poor moisture resistance | Better moisture resistance |

| Flexibility | Less flexible, more brittle | More flexible and durable |

| Common Uses | Food packaging, gift wrap | Photography overlays, apparel, packaging |

| Environmental Impact | Eco-friendly, sustainable | Less eco-friendly due to acetylation process |

| Cost | Generally lower cost | Higher cost due to processing |

Overview of Cellophane and Acetate Sheeting

Cellophane sheeting is a transparent, biodegradable film made from cellulose, known for its excellent moisture barrier and breathability, commonly used in food packaging to maintain freshness. Acetate sheeting, derived from cellulose acetate, offers higher durability and resistance to oils and chemicals, making it suitable for photographic films, decorative applications, and fashion accessories. Both materials are cellulose-based but differ in chemical treatment and performance characteristics, influencing their specific industrial uses.

Composition and Material Differences

Cellophane sheeting is made from regenerated cellulose derived from wood pulp, making it biodegradable and eco-friendly, while acetate sheeting is composed of cellulose acetate, a synthetic derivative that offers increased durability and resistance to moisture. Cellophane typically has a natural, transparent appearance with high breathability, whereas acetate provides a glossier finish and better chemical resistance. The fundamental difference lies in their polymer structures, influencing their respective behavior in packaging and industrial applications.

Production Processes Compared

Cellophane sheeting is produced through the viscose process, where cellulose is treated with sodium hydroxide and carbon disulfide to form cellulose xanthate before being regenerated into transparent film. Acetate sheeting is made by chemically acetylating cellulose fibers with acetic anhydride, creating cellulose acetate that is then plasticized and cast into sheets. The key distinction lies in cellophane's regeneration of cellulose for clarity and biodegradability, while acetate undergoes esterification, resulting in a more flexible, durable, and less water-sensitive material.

Environmental Impact and Biodegradability

Cellophane sheeting, derived from cellulose, is biodegradable and compostable, breaking down naturally within weeks and reducing landfill waste significantly compared to synthetic plastics. Acetate sheeting, while also cellulose-based, often contains plasticizers and synthetic additives that hinder its biodegradability and contribute to longer environmental persistence. The environmental impact of cellophane is lower due to its renewable raw materials and minimal chemical processing, making it a more sustainable choice over acetate sheeting in eco-conscious packaging solutions.

Clarity and Aesthetic Qualities

Cellophane sheeting offers superior clarity with its high transparency and natural gloss, making it ideal for packaging that requires a clear view of the product. Acetate sheeting, while also transparent, tends to have a slightly hazier appearance and less brilliance, impacting its aesthetic appeal. The natural sheen and crispness of cellophane enhance visual presentation more effectively than acetate, especially in applications emphasizing clarity and attractiveness.

Strength and Durability Assessment

Cellophane sheeting offers moderate strength with good flexibility but tends to degrade under prolonged moisture exposure, reducing its durability. Acetate sheeting demonstrates higher tensile strength and improved resistance to humidity and chemicals, making it more durable in varied environmental conditions. When assessing long-term applications requiring resilience, acetate sheeting generally outperforms cellophane in strength and durability metrics.

Moisture and Gas Barrier Properties

Cellophane sheeting offers superior moisture vapor barrier properties compared to acetate sheeting, making it ideal for packaging applications requiring high moisture resistance. However, acetate sheeting typically provides better oxygen and gas barrier performance, which is crucial for preserving freshness and preventing oxidation. The distinct barrier characteristics of cellophane and acetate influence their selection based on specific packaging requirements involving moisture control and gas permeability.

Applications in Packaging and Crafting

Cellophane sheeting, renowned for its biodegradable and moisture-resistant properties, is widely used in food packaging to maintain freshness and provide a clear, eco-friendly wrap. Acetate sheeting, favored for its superior clarity and flexibility, is commonly utilized in crafting projects, gift wrapping, and stationery due to its easy-to-cut and fold nature. Both materials serve distinct roles in packaging and crafting, with cellophane excelling in sustainable food protection and acetate offering versatile design applications.

Pricing and Market Availability

Cellophane sheeting generally commands higher prices due to its biodegradable nature and limited production scale compared to acetate sheeting, which benefits from widespread manufacturing and cost-effective raw materials. Market availability for acetate sheeting is broader, given its extensive use in packaging and photographic films, whereas cellophane's niche demand restricts its distribution primarily to eco-friendly packaging sectors. Price fluctuations in cellophane are driven by cellulose source costs and environmental regulations, contrasting with acetate's price stability anchored by synthetic acetate production.

Choosing Between Cellophane and Acetate Sheeting

Cellophane sheeting offers superior moisture barrier properties and biodegradability, making it ideal for food packaging and eco-friendly applications. Acetate sheeting provides greater clarity, flexibility, and heat resistance, preferred for photographic films, book covers, and decorative laminates. Selecting between cellophane and acetate sheeting depends on factors such as desired durability, environmental impact, and specific application requirements.

Cellophane Sheeting vs Acetate Sheeting Infographic

materialdif.com

materialdif.com