Transparent cellophane offers clear visibility, making it ideal for showcasing products while protecting them from moisture and dust. Opaque cellophane provides a solid barrier, ensuring privacy and preventing light exposure, which helps preserve light-sensitive items. Selecting between transparent and opaque cellophane depends on the desired balance between product visibility and protection requirements.

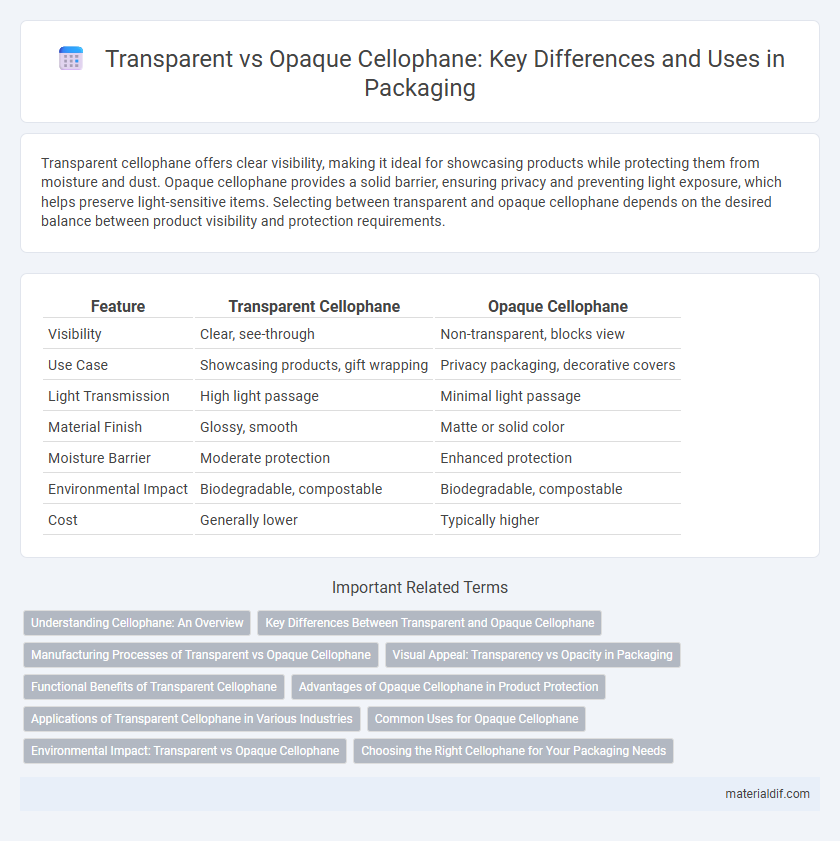

Table of Comparison

| Feature | Transparent Cellophane | Opaque Cellophane |

|---|---|---|

| Visibility | Clear, see-through | Non-transparent, blocks view |

| Use Case | Showcasing products, gift wrapping | Privacy packaging, decorative covers |

| Light Transmission | High light passage | Minimal light passage |

| Material Finish | Glossy, smooth | Matte or solid color |

| Moisture Barrier | Moderate protection | Enhanced protection |

| Environmental Impact | Biodegradable, compostable | Biodegradable, compostable |

| Cost | Generally lower | Typically higher |

Understanding Cellophane: An Overview

Transparent cellophane offers high clarity and allows full visibility of the product inside, making it ideal for packaging that showcases contents. Opaque cellophane provides a solid, light-blocking barrier, enhancing privacy and protecting items from UV light and moisture. Selecting between transparent and opaque cellophane depends on the desired balance between visibility and protection for packaging applications.

Key Differences Between Transparent and Opaque Cellophane

Transparent cellophane allows clear visibility of the contents inside, making it ideal for showcasing products while providing moisture resistance and breathability. Opaque cellophane, on the other hand, conceals the contents, offering greater privacy and UV protection, often used for decorative wraps and gift packaging. The choice between transparent and opaque cellophane depends on the need for visibility, protection, and aesthetic appeal in packaging applications.

Manufacturing Processes of Transparent vs Opaque Cellophane

Transparent cellophane is manufactured through a process of viscose regeneration, where cellulose is dissolved, extruded, and stretched to create a clear, thin film with high light transmission. Opaque cellophane undergoes additional treatments such as coating with pigments or incorporating fillers during the film formation stage to scatter light and reduce transparency. These differing manufacturing steps impact the film's clarity, moisture permeability, and mechanical properties, making each suitable for distinct packaging applications.

Visual Appeal: Transparency vs Opacity in Packaging

Transparent cellophane enhances product visibility by allowing consumers to see the contents clearly, boosting trust and appeal in retail environments. Opaque cellophane, with its solid or patterned finish, offers a unique branding opportunity by concealing the product while emphasizing design elements and color schemes. Choosing between transparent and opaque cellophane depends on marketing goals, whether to highlight the product's quality or to create a distinct brand identity through packaging aesthetics.

Functional Benefits of Transparent Cellophane

Transparent cellophane offers superior visibility, allowing consumers to clearly see the product inside, which enhances product appeal and trust. Its moisture-resistant and breathable properties help maintain freshness while preventing condensation buildup. This clarity and functional barrier make transparent cellophane ideal for packaging fresh food, gifts, and delicate items that require protection without compromising display quality.

Advantages of Opaque Cellophane in Product Protection

Opaque cellophane offers superior protection against light exposure, preserving the quality and extending the shelf life of light-sensitive products. Its ability to block UV rays prevents degradation of food, cosmetics, and pharmaceuticals, ensuring product integrity. Unlike transparent cellophane, opaque varieties also provide enhanced privacy and concealment, improving branding and preventing tampering.

Applications of Transparent Cellophane in Various Industries

Transparent cellophane is widely used in food packaging to showcase product freshness while providing a moisture barrier and tamper evidence. In the retail industry, it enhances product visibility and aesthetic appeal for items such as gift baskets, flowers, and cosmetics. Its biodegradability and clarity also make it a preferred choice in pharmaceutical packaging, where it protects products without obscuring labeling.

Common Uses for Opaque Cellophane

Opaque cellophane is commonly used in packaging where light protection and product concealment are essential, such as wrapping confectionery, bakery items, and cosmetics to maintain freshness and prevent UV damage. It is favored for gift wrapping and promotional packaging because it provides a colorful, decorative appearance while hiding the contents inside. Industries utilize opaque cellophane for privacy in packaging and to enhance shelf appeal through vibrant printing options.

Environmental Impact: Transparent vs Opaque Cellophane

Transparent cellophane, derived from cellulose, is biodegradable and compostable, reducing environmental pollution compared to plastic alternatives. Opaque cellophane often contains added dyes or fillers that may affect its biodegradability and increase environmental residues. Choosing clear, uncolored cellophane supports sustainable packaging by facilitating natural decomposition and minimizing ecological footprint.

Choosing the Right Cellophane for Your Packaging Needs

Transparent cellophane offers clear visibility of products, enhancing shelf appeal and allowing customers to easily assess quality, which is ideal for food items and gift wrapping. Opaque cellophane provides UV protection and privacy, making it suitable for light-sensitive products or confidential packaging. Evaluating product display requirements and protection needs ensures the selection of the most effective cellophane type for optimal packaging performance.

Transparent Cellophane vs Opaque Cellophane Infographic

materialdif.com

materialdif.com