Regenerated cellulose is derived from natural cellulose fibers treated to create a transparent, biodegradable film ideal for eco-friendly packaging. Nitrocellulose, on the other hand, is chemically modified cellulose nitrate that is highly flammable and used primarily in lacquers, explosives, and films requiring rapid drying. While regenerated cellulose emphasizes sustainability and safety, nitrocellulose offers enhanced durability and specific industrial applications.

Table of Comparison

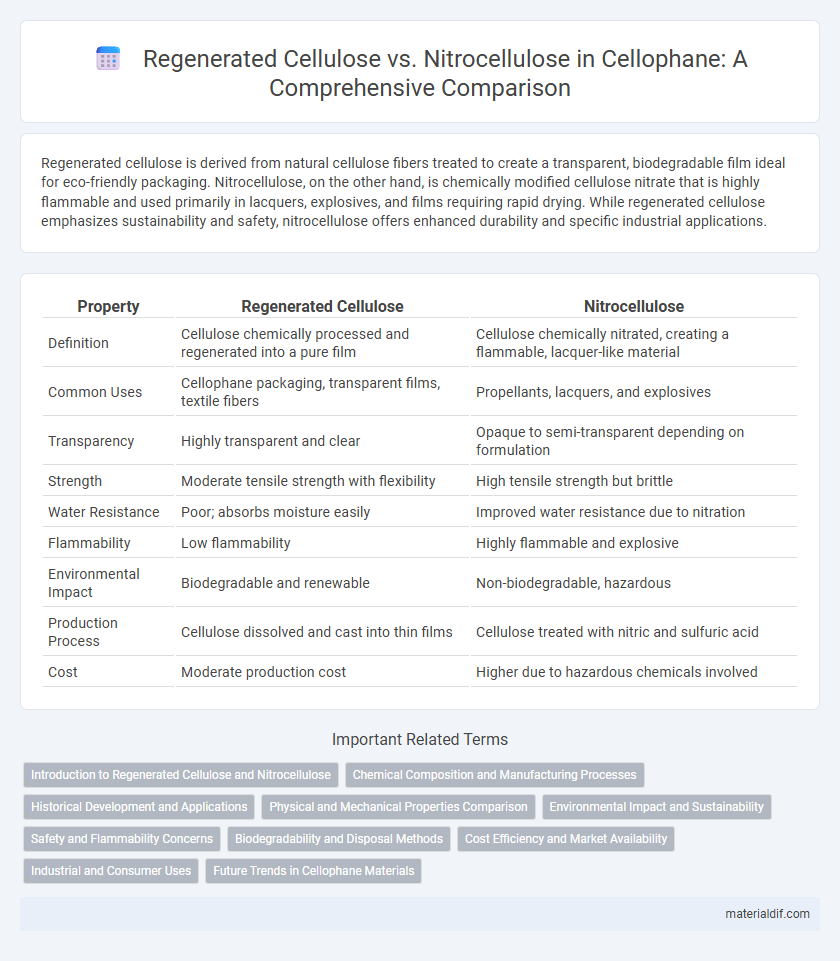

| Property | Regenerated Cellulose | Nitrocellulose |

|---|---|---|

| Definition | Cellulose chemically processed and regenerated into a pure film | Cellulose chemically nitrated, creating a flammable, lacquer-like material |

| Common Uses | Cellophane packaging, transparent films, textile fibers | Propellants, lacquers, and explosives |

| Transparency | Highly transparent and clear | Opaque to semi-transparent depending on formulation |

| Strength | Moderate tensile strength with flexibility | High tensile strength but brittle |

| Water Resistance | Poor; absorbs moisture easily | Improved water resistance due to nitration |

| Flammability | Low flammability | Highly flammable and explosive |

| Environmental Impact | Biodegradable and renewable | Non-biodegradable, hazardous |

| Production Process | Cellulose dissolved and cast into thin films | Cellulose treated with nitric and sulfuric acid |

| Cost | Moderate production cost | Higher due to hazardous chemicals involved |

Introduction to Regenerated Cellulose and Nitrocellulose

Regenerated cellulose is a chemically purified form of cellulose, derived from natural sources like wood pulp or cotton fibers, and is used extensively in producing cellophane films due to its transparency, biodegradability, and flexibility. Nitrocellulose, on the other hand, is cellulose treated with nitric acid and sulfuric acid, resulting in a highly flammable, resinous compound primarily used in lacquers, explosives, and early photographic films. While regenerated cellulose emphasizes eco-friendly packaging applications, nitrocellulose's chemical modifications focus on industrial functions requiring durability and rapid drying properties.

Chemical Composition and Manufacturing Processes

Regenerated cellulose is produced by dissolving natural cellulose and then reforming it into fibers through processes such as the viscose or lyocell methods, resulting in a pure cellulose product chemically identical to raw cellulose. Nitrocellulose is created by treating cellulose with nitric acid and sulfuric acid, introducing nitro groups that increase its flammability and volatility, making it useful in films and explosives. The chemical modification in nitrocellulose alters its properties significantly, while regenerated cellulose maintains the original cellulose polymer structure but changes its physical form.

Historical Development and Applications

Regenerated cellulose, developed in the late 19th century by Swiss chemist Jacques Brandenberger, revolutionized packaging with the invention of cellophane, prized for its transparency and moisture resistance. Nitrocellulose, synthesized earlier in the 1830s and widely used in the production of early film and explosives, played a critical role in the industrial and military sectors before being supplanted in many applications by safer cellulose derivatives. The historical development of regenerated cellulose emphasized environmentally friendly packaging materials, while nitrocellulose's applications centered on high-energy materials and photographic films.

Physical and Mechanical Properties Comparison

Regenerated cellulose exhibits excellent tensile strength, flexibility, and moisture resistance, making it ideal for packaging and fiber applications. Nitrocellulose, with its higher flammability and rigidity, offers superior mechanical robustness and quick drying but lacks the elasticity of regenerated cellulose. The physical durability of regenerated cellulose supports biodegradable uses, whereas nitrocellulose's mechanical properties favor industrial coatings and explosives.

Environmental Impact and Sustainability

Regenerated cellulose, derived from natural cellulose fibers, is biodegradable and has a lower environmental impact due to its renewable sourcing and reduced chemical processing compared to nitrocellulose. Nitrocellulose, synthesized through nitro-functionalization of cellulose, poses environmental challenges including toxicity and flammability, alongside difficulties in safe disposal and recycling. Sustainable packaging solutions prioritize regenerated cellulose films for their eco-friendly lifecycle and compatibility with circular economy principles.

Safety and Flammability Concerns

Regenerated cellulose is generally safer and less flammable than nitrocellulose, which is highly combustible due to its nitrate groups making it an explosive material used in propellants and films. Nitrocellulose requires strict handling protocols to prevent accidental ignition, whereas regenerated cellulose is more stable and widely used in packaging and textiles without significant fire risks. The lower flammability and enhanced safety profile of regenerated cellulose make it preferable for consumer applications where fire hazard reduction is critical.

Biodegradability and Disposal Methods

Regenerated cellulose is biodegradable and breaks down naturally through microbial activity, making it an environmentally friendly option for packaging and film applications. Nitrocellulose, chemically modified with nitrates, is less biodegradable and poses challenges for disposal due to its flammability and potential environmental hazards. Proper disposal methods for nitrocellulose include controlled incineration and chemical neutralization to mitigate pollution and safety risks.

Cost Efficiency and Market Availability

Regenerated cellulose offers higher cost efficiency compared to nitrocellulose due to its lower production expenses and easier raw material sourcing, making it more accessible in the global market. While nitrocellulose has specialized applications in lacquers and explosives, its complex manufacturing process and volatility increase costs and limit widespread availability. Regenerated cellulose dominates sectors like textiles and packaging thanks to consistent supply chains and scalable manufacturing technologies.

Industrial and Consumer Uses

Regenerated cellulose, derived from cellulose fibers chemically treated and reformed, finds extensive use in industrial applications such as packaging films, textiles, and hygiene products due to its biodegradability and strength. Nitrocellulose, a cellulose nitrate compound, is primarily utilized in industrial settings for producing lacquers, explosives, and inks because of its flammability and film-forming properties, though its applications in consumer goods are limited by safety concerns. The demand for eco-friendly materials has increased the preference for regenerated cellulose in consumer packaging and filtration, while nitrocellulose remains crucial in specialized industrial manufacturing.

Future Trends in Cellophane Materials

Future trends in cellophane materials emphasize advancements in regenerated cellulose films, which offer enhanced biodegradability and mechanical strength compared to nitrocellulose variants. Innovations in bio-based coatings and nanocomposite integration are driving improved barrier properties and sustainability in regenerated cellulose cellophane. Research on reducing environmental impact through green manufacturing processes highlights the shift towards fully compostable and recyclable cellophane products.

Regenerated Cellulose vs Nitrocellulose Infographic

materialdif.com

materialdif.com