Cellophane tape is made from cellulose, offering a biodegradable and eco-friendly option compared to synthetic transparent tape. Transparent tape, typically produced from plastic materials like polypropylene, provides stronger adhesion and greater durability for long-term use. Choosing between the two depends on the need for environmental sustainability or enhanced performance in sealing and packaging.

Table of Comparison

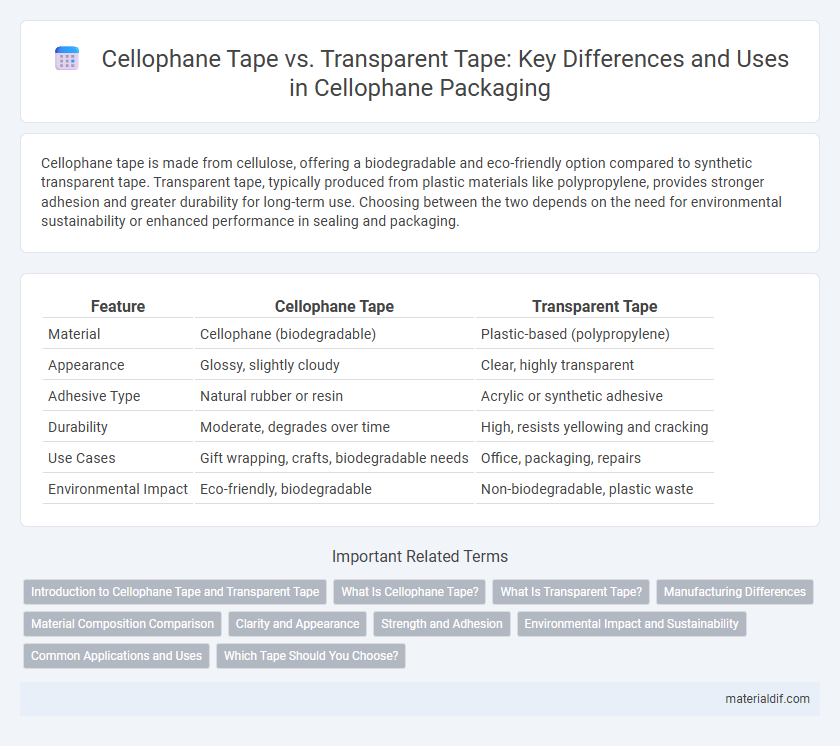

| Feature | Cellophane Tape | Transparent Tape |

|---|---|---|

| Material | Cellophane (biodegradable) | Plastic-based (polypropylene) |

| Appearance | Glossy, slightly cloudy | Clear, highly transparent |

| Adhesive Type | Natural rubber or resin | Acrylic or synthetic adhesive |

| Durability | Moderate, degrades over time | High, resists yellowing and cracking |

| Use Cases | Gift wrapping, crafts, biodegradable needs | Office, packaging, repairs |

| Environmental Impact | Eco-friendly, biodegradable | Non-biodegradable, plastic waste |

Introduction to Cellophane Tape and Transparent Tape

Cellophane tape, made from cellulose film, offers a glossy finish and strong adhesion suitable for various packaging and sealing needs, while transparent tape typically utilizes a plastic base like polypropylene for durability and clear visibility. Cellophane tape is biodegradable and often preferred for eco-friendly applications, contrasting with transparent tape's versatility and resistance to moisture and stretching. Both tapes provide reliable bonding but differ mainly in material composition and environmental impact.

What Is Cellophane Tape?

Cellophane tape, made from cellulose film, is a biodegradable adhesive tape often used for packaging and light sealing tasks. It is distinct from transparent tape, which is typically made of plastic materials like polypropylene or polyester, offering greater durability and water resistance. Cellophane tape's eco-friendly composition makes it preferable for environmentally conscious applications compared to synthetic transparent tapes.

What Is Transparent Tape?

Transparent tape, also known as clear tape or Scotch tape, is a pressure-sensitive adhesive tape made from cellulose or plastic film coated with a transparent adhesive. It offers strength and clarity, making it ideal for sealing, wrapping, and light-duty repairs without obscuring the underlying surface. Unlike cellophane tape, which is derived from regenerated cellulose films, transparent tape is primarily composed of synthetic materials like polypropylene or polyester, enhancing durability and moisture resistance.

Manufacturing Differences

Cellophane tape is made from regenerated cellulose derived from plant fibers, undergoing a process that includes cellulose extraction, purification, and plasticization to create a biodegradable film. Transparent tape typically uses a synthetic polymer base, such as polypropylene, produced through polymerization and extrusion, resulting in a more durable and moisture-resistant product. The manufacturing differences impact environmental sustainability, adhesive properties, and flexibility of each tape type.

Material Composition Comparison

Cellophane tape is made from regenerated cellulose, a natural polymer derived from wood pulp, making it biodegradable and eco-friendly. Transparent tape typically consists of a synthetic plastic base such as polypropylene or cellulose acetate, which provides greater durability and moisture resistance but is less environmentally friendly. The choice between these tapes hinges on the balance of material sustainability versus performance requirements.

Clarity and Appearance

Cellophane tape typically offers a higher level of clarity due to its natural cellulose base, making it less yellow and more transparent compared to many synthetic transparent tapes. Transparent tapes often contain plasticizers that can cause slight haziness or a glossy finish, which may affect the overall appearance on paper or packaging. Choosing cellophane tape ensures a cleaner, more invisible adhesive line, ideal for presentations or gift wrapping where appearance matters.

Strength and Adhesion

Cellophane tape typically offers moderate strength with a focus on flexibility and eco-friendliness, making it ideal for lightweight packaging and general use. Transparent tape often features higher adhesion and tensile strength due to synthetic backing materials like polypropylene, providing superior durability for heavier-duty tasks. Choosing between the two depends on the required balance between environmental impact and the strength of the adhesive bond.

Environmental Impact and Sustainability

Cellophane tape, made from cellulose derived from wood pulp, is biodegradable and breaks down naturally, making it a more environmentally friendly option compared to traditional transparent tape, which commonly uses petroleum-based plastics like polypropylene that persist in landfills. The production of cellophane tape involves fewer fossil fuel resources and generates less pollution, enhancing its sustainability profile. Choosing cellophane tape helps reduce plastic waste and supports renewable resource use in adhesive applications.

Common Applications and Uses

Cellophane tape is often preferred for gift wrapping and light packaging due to its natural cellulose base, which provides gentle adhesion and easy tearability. Transparent tape, made from synthetic materials like polypropylene, is widely used for sealing boxes, office tasks, and heavier-duty applications because of its superior strength and moisture resistance. Both tapes share common uses in labeling and mending paper products, but transparent tape offers enhanced durability for industrial and everyday repairs.

Which Tape Should You Choose?

Cellophane tape and transparent tape differ primarily in material composition and adhesive strength; cellophane tape is made from cellulose and offers moderate durability, while transparent tape is usually made from polypropylene with stronger adhesive properties and higher resistance to moisture. Choose cellophane tape for light-duty applications like gift wrapping and temporary fixes, whereas transparent tape is ideal for heavy-duty tasks, such as sealing packages or repairing torn documents. Consider factors like adhesive strength, flexibility, and transparency to select the tape best suited for your specific needs.

Cellophane Tape vs Transparent Tape Infographic

materialdif.com

materialdif.com