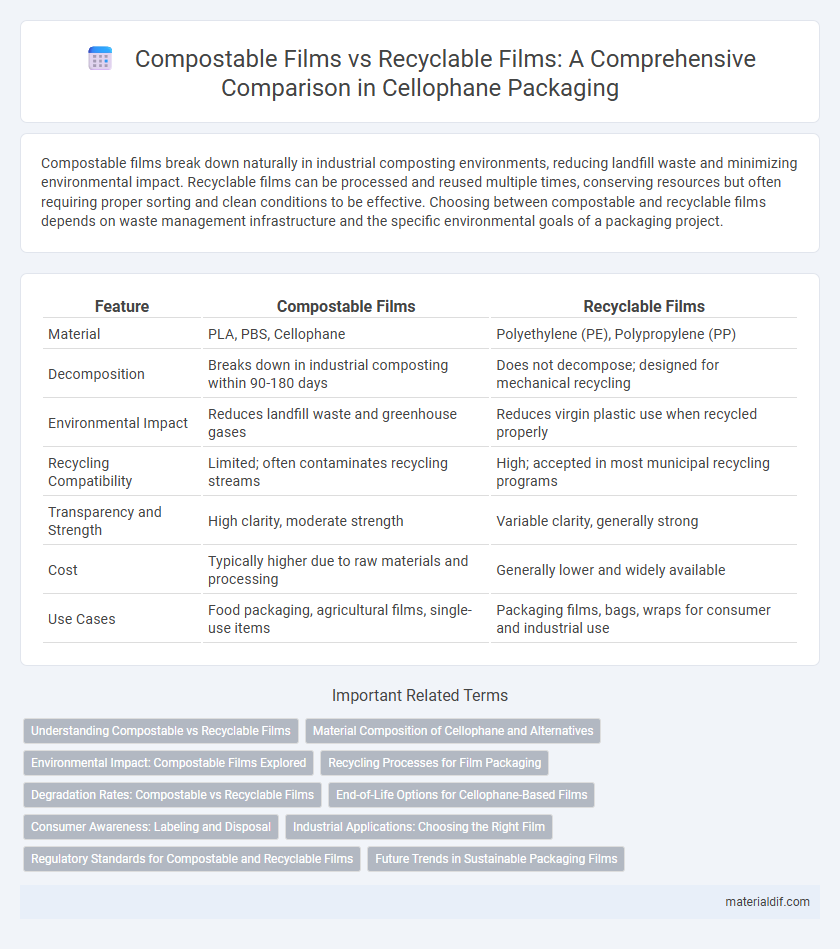

Compostable films break down naturally in industrial composting environments, reducing landfill waste and minimizing environmental impact. Recyclable films can be processed and reused multiple times, conserving resources but often requiring proper sorting and clean conditions to be effective. Choosing between compostable and recyclable films depends on waste management infrastructure and the specific environmental goals of a packaging project.

Table of Comparison

| Feature | Compostable Films | Recyclable Films |

|---|---|---|

| Material | PLA, PBS, Cellophane | Polyethylene (PE), Polypropylene (PP) |

| Decomposition | Breaks down in industrial composting within 90-180 days | Does not decompose; designed for mechanical recycling |

| Environmental Impact | Reduces landfill waste and greenhouse gases | Reduces virgin plastic use when recycled properly |

| Recycling Compatibility | Limited; often contaminates recycling streams | High; accepted in most municipal recycling programs |

| Transparency and Strength | High clarity, moderate strength | Variable clarity, generally strong |

| Cost | Typically higher due to raw materials and processing | Generally lower and widely available |

| Use Cases | Food packaging, agricultural films, single-use items | Packaging films, bags, wraps for consumer and industrial use |

Understanding Compostable vs Recyclable Films

Compostable films, made from bio-based materials like cellulose or PLA, break down naturally in composting environments, reducing landfill waste and supporting soil health. Recyclable films, typically composed of polyethylene or other plastics, can be processed and reused in manufacturing but require proper sorting and recycling infrastructure. Understanding the distinction helps businesses choose sustainable packaging solutions aligned with their environmental impact goals.

Material Composition of Cellophane and Alternatives

Cellophane is made from regenerated cellulose derived from wood pulp, making it inherently biodegradable and compostable compared to traditional plastic recyclable films composed of polyethylene or polypropylene. Compostable films like cellophane break down into natural elements under industrial or home composting conditions, reducing environmental impact significantly. Alternative films such as PLA-based bioplastics offer compostability but rely on fermentation of corn starch, whereas cellophane's wood pulp origin provides a renewable source with lower carbon footprint.

Environmental Impact: Compostable Films Explored

Compostable films break down naturally in commercial composting environments, reducing landfill waste and minimizing soil contamination compared to traditional recyclable films. Their biodegradability lowers greenhouse gas emissions by avoiding prolonged decomposition processes associated with conventional plastics. These films support circular economy principles by returning organic materials to the ecosystem, promoting sustainable packaging solutions.

Recycling Processes for Film Packaging

Compostable films, made from natural polymers like cellulose, break down through biological processes in industrial composting facilities, producing no toxic residues. Recyclable films, typically polyethylene-based, undergo mechanical recycling where they are collected, cleaned, shredded, and reprocessed into pellets for new packaging products. Recycling processes for film packaging prioritize contamination control and material sorting to maintain high-quality output and reduce landfill waste.

Degradation Rates: Compostable vs Recyclable Films

Compostable films, typically made from plant-based materials like cellulose, degrade rapidly within a few weeks to months under industrial composting conditions, breaking down into water, carbon dioxide, and biomass. Recyclable films, often polyethylene-based, do not degrade but undergo mechanical or chemical recycling processes that preserve material value but require specific facilities and conditions. The faster degradation rate of compostable films significantly reduces environmental persistence compared to recyclable films, which depend on recycling infrastructure efficacy to minimize landfill impact.

End-of-Life Options for Cellophane-Based Films

Cellophane-based films offer versatile end-of-life options, being both compostable and recyclable under specific conditions. Compostable cellophane breaks down naturally within industrial composting facilities, reducing environmental impact and supporting circular waste management. Recyclable cellophane films, while less common, require proper sorting to ensure they enter appropriate recycling streams, minimizing contamination and enabling material recovery.

Consumer Awareness: Labeling and Disposal

Clear labeling on compostable films, such as certified compostability marks, significantly enhances consumer awareness and proper disposal. Recyclable films require precise recycling codes and instructions to prevent contamination in recycling streams. Effective communication through standardized labels reduces consumer confusion, promoting environmentally responsible behavior in film disposal.

Industrial Applications: Choosing the Right Film

Compostable films, made from natural polymers like cellulose, offer industrial applications focused on sustainability and biodegradability, making them ideal for packaging in food and agricultural sectors where waste reduction is crucial. Recyclable films, typically derived from polyethylene or polypropylene, provide durability and ease of processing in large-scale manufacturing, suitable for packaging that requires extended shelf life and mechanical strength. Selecting the right film depends on the specific industrial requirement for environmental impact versus performance, with compostable films excelling in circular economy initiatives and recyclable films favored for their established infrastructure and cost-effectiveness.

Regulatory Standards for Compostable and Recyclable Films

Compostable films must comply with standards such as ASTM D6400 or EN 13432, ensuring they biodegrade under industrial composting conditions without leaving toxic residues. Recyclable films adhere to regulations like the FDA's guidelines for food contact materials and certification schemes such as the How2Recycle label to verify recyclability through established municipal programs. Regulatory frameworks prioritize environmental safety, biodegradability verification for compostable films, and contamination prevention for recyclable films to enhance sustainable packaging practices.

Future Trends in Sustainable Packaging Films

Compostable films, derived from renewable resources like cellulose and starch, offer biodegradability within months, making them ideal for reducing landfill waste and supporting circular economy models. Recyclable films, often made from polyethylene or polypropylene, emphasize material recovery and reuse, fostering resource efficiency and minimizing environmental footprint through advanced sorting technologies. Future trends in sustainable packaging films highlight the integration of hybrid materials and bio-based additives to enhance performance while meeting regulatory demands and consumer preferences for eco-friendly packaging solutions.

Compostable films vs Recyclable films Infographic

materialdif.com

materialdif.com