Bio-based Cellophane is derived from renewable plant materials, offering a sustainable alternative to conventional petroleum-based films that rely on fossil fuels. It provides excellent biodegradability and reduces environmental impact by minimizing plastic waste accumulation. Compared to petroleum-based films, bio-based Cellophane supports circular economy principles while maintaining comparable barrier properties and versatility for packaging applications.

Table of Comparison

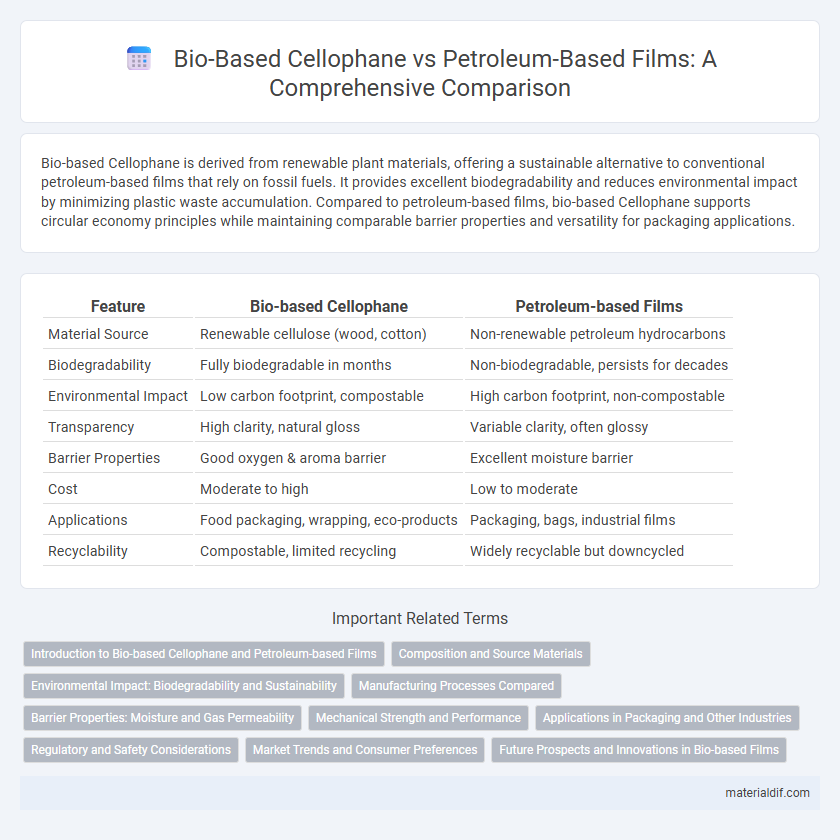

| Feature | Bio-based Cellophane | Petroleum-based Films |

|---|---|---|

| Material Source | Renewable cellulose (wood, cotton) | Non-renewable petroleum hydrocarbons |

| Biodegradability | Fully biodegradable in months | Non-biodegradable, persists for decades |

| Environmental Impact | Low carbon footprint, compostable | High carbon footprint, non-compostable |

| Transparency | High clarity, natural gloss | Variable clarity, often glossy |

| Barrier Properties | Good oxygen & aroma barrier | Excellent moisture barrier |

| Cost | Moderate to high | Low to moderate |

| Applications | Food packaging, wrapping, eco-products | Packaging, bags, industrial films |

| Recyclability | Compostable, limited recycling | Widely recyclable but downcycled |

Introduction to Bio-based Cellophane and Petroleum-based Films

Bio-based cellophane is derived from renewable cellulose sources, offering a biodegradable and sustainable alternative to traditional petroleum-based films. Petroleum-based films, commonly made from polyethylene or polypropylene, rely on fossil fuels, contributing to environmental concerns due to their non-biodegradable nature and carbon footprint. The shift towards bio-based cellophane addresses the demand for eco-friendly packaging materials while maintaining clarity, flexibility, and barrier properties essential for food preservation and other applications.

Composition and Source Materials

Bio-based cellophane is derived from cellulose extracted from renewable plant sources such as wood pulp and cotton fibers, making it biodegradable and environmentally friendly. In contrast, petroleum-based films like polyethylene and polypropylene are synthesized from non-renewable fossil fuels, resulting in long-lasting plastic materials that contribute to environmental pollution. The primary compositional difference lies in bio-based cellophane's natural polymer matrix versus the synthetic polymers used in petroleum-based films.

Environmental Impact: Biodegradability and Sustainability

Bio-based cellophane offers significant environmental advantages over petroleum-based films due to its biodegradability and renewable origin, which reduces landfill waste and microplastic pollution. Made from cellulose derived from wood pulp or cotton fibers, bio-based cellophane decomposes naturally within weeks to months, unlike petroleum-based films that may persist for decades. Its sustainable production cycles lower carbon footprints and reliance on fossil fuels, positioning bio-based cellophane as a key material in eco-friendly packaging solutions.

Manufacturing Processes Compared

Bio-based cellophane is derived from cellulose, typically sourced from wood pulp or cotton fibers, undergoing a regeneration process involving cellulose dissolution and reprecipitation, which results in a biodegradable and compostable film. Petroleum-based films, such as polyethylene and polypropylene, are produced through polymerization of hydrocarbons extracted from crude oil via energy-intensive processes with significant environmental impact. Manufacturing bio-based cellophane consumes renewable raw materials and involves fewer greenhouse gas emissions compared to the fossil fuel extraction and refining steps required for petroleum-based film production.

Barrier Properties: Moisture and Gas Permeability

Bio-based cellophane exhibits superior moisture barrier properties compared to petroleum-based films due to its dense cellulose structure that limits water vapor transmission. In contrast, petroleum-based films like polyethylene and polypropylene typically offer better gas barrier performance, particularly against oxygen and carbon dioxide, enhancing food preservation. Optimizing barrier properties in bio-based cellophane involves surface coatings or multilayer constructions to match the gas impermeability levels of synthetic films while maintaining biodegradability.

Mechanical Strength and Performance

Bio-based cellophane exhibits mechanical strength comparable to or exceeding that of traditional petroleum-based films, offering enhanced tensile strength and flexibility essential for packaging applications. Its biodegradability and renewable origins provide environmental advantages without compromising performance characteristics such as moisture barrier and heat resistance. The film's superior oxygen permeability control further supports product preservation, making bio-based cellophane a sustainable yet effective alternative to conventional petroleum-derived films.

Applications in Packaging and Other Industries

Bio-based cellophane offers a sustainable alternative to petroleum-based films, commonly used in food packaging, pharmaceuticals, and cosmetics due to its biodegradability and excellent barrier properties against moisture and oxygen. In packaging industries, bio-based cellophane enhances product shelf life while reducing environmental impact, meeting growing consumer demand for eco-friendly materials. Beyond packaging, bio-based cellophane finds applications in textiles and gift wraps, leveraging its transparency and compostability to replace conventional plastic films.

Regulatory and Safety Considerations

Bio-based cellophane offers significant regulatory advantages over petroleum-based films due to its compliance with stringent environmental and safety standards, including FDA and EU food-contact approvals. Its biodegradability reduces concerns related to microplastic pollution, aligning with increasing global regulatory emphasis on sustainable packaging materials. Safety considerations highlight bio-based cellophane's lower toxicity and reduced risk of harmful chemical migration compared to petroleum-derived alternatives, enhancing consumer health protection.

Market Trends and Consumer Preferences

Bio-based cellophane is gaining significant traction in the packaging market due to rising consumer demand for sustainable, eco-friendly alternatives to petroleum-based films. Market trends indicate a steady shift towards bio-based films, driven by increasing environmental regulations and growing awareness of plastic pollution. Consumer preferences favor biodegradable and compostable materials, positioning bio-based cellophane as a preferred choice in sectors such as food packaging and personal care.

Future Prospects and Innovations in Bio-based Films

Bio-based cellophane offers a sustainable alternative to petroleum-based films by utilizing renewable raw materials such as cellulose from wood pulp, significantly reducing carbon footprint and environmental impact. Innovations in bio-based films focus on enhancing barrier properties, biodegradability, and mechanical strength through nanocellulose reinforcement and enzymatic modifications. Future prospects include scalable production technologies and integration with smart packaging features, driving a shift towards eco-friendly, high-performance packaging solutions.

Bio-based Cellophane vs Petroleum-based Films Infographic

materialdif.com

materialdif.com