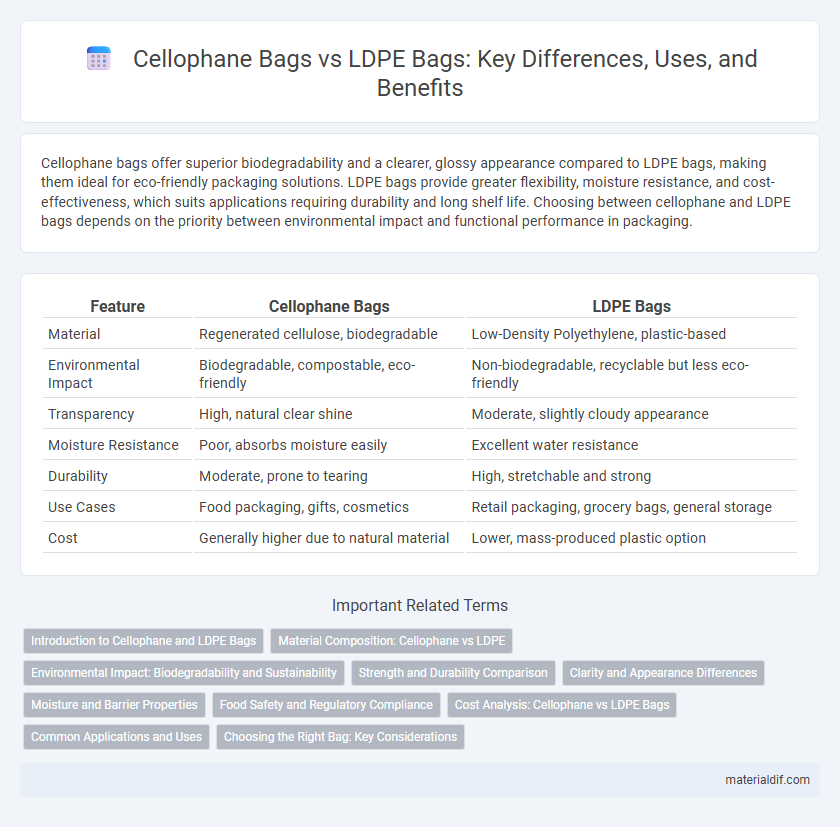

Cellophane bags offer superior biodegradability and a clearer, glossy appearance compared to LDPE bags, making them ideal for eco-friendly packaging solutions. LDPE bags provide greater flexibility, moisture resistance, and cost-effectiveness, which suits applications requiring durability and long shelf life. Choosing between cellophane and LDPE bags depends on the priority between environmental impact and functional performance in packaging.

Table of Comparison

| Feature | Cellophane Bags | LDPE Bags |

|---|---|---|

| Material | Regenerated cellulose, biodegradable | Low-Density Polyethylene, plastic-based |

| Environmental Impact | Biodegradable, compostable, eco-friendly | Non-biodegradable, recyclable but less eco-friendly |

| Transparency | High, natural clear shine | Moderate, slightly cloudy appearance |

| Moisture Resistance | Poor, absorbs moisture easily | Excellent water resistance |

| Durability | Moderate, prone to tearing | High, stretchable and strong |

| Use Cases | Food packaging, gifts, cosmetics | Retail packaging, grocery bags, general storage |

| Cost | Generally higher due to natural material | Lower, mass-produced plastic option |

Introduction to Cellophane and LDPE Bags

Cellophane bags are made from regenerated cellulose derived from wood pulp, offering a biodegradable and breathable packaging option ideal for food preservation. LDPE bags, composed of low-density polyethylene, provide flexibility, moisture resistance, and durability but are less eco-friendly due to their plastic composition. Both materials serve different packaging needs, with cellophane prioritized for sustainable applications and LDPE favored for strength and waterproof properties.

Material Composition: Cellophane vs LDPE

Cellophane bags are made from regenerated cellulose derived from wood pulp, offering biodegradability and a natural, transparent finish, while LDPE bags are composed of low-density polyethylene, a petroleum-based plastic known for flexibility and durability. Cellophane's cellulose structure allows for moisture resistance and breathability, making it ideal for packaging fresh produce and bakery items, whereas LDPE's synthetic polymer matrix provides superior water resistance and chemical inertness. The environmental impact of cellophane is generally lower due to its compostable nature compared to LDPE, which can take hundreds of years to decompose in landfill conditions.

Environmental Impact: Biodegradability and Sustainability

Cellophane bags, made from cellulose derived from wood pulp, are biodegradable and compostable, breaking down naturally within weeks to months without releasing harmful microplastics. LDPE bags, composed of low-density polyethylene, persist in the environment for hundreds of years, contributing to plastic pollution and marine ecosystem damage due to their resistance to biodegradation. The sustainable sourcing and biodegradability of cellophane bags make them a more eco-friendly alternative to LDPE bags, which rely on fossil fuels and pose long-term environmental risks.

Strength and Durability Comparison

Cellophane bags offer moderate strength and are biodegradable, making them suitable for lightweight packaging but less resistant to tearing compared to LDPE bags. LDPE bags provide superior durability and flexibility, with higher resistance to punctures, making them ideal for heavier or sharp-edged items. The tensile strength of LDPE bags typically exceeds that of cellophane, ensuring longer-lasting protection in various storage and transportation conditions.

Clarity and Appearance Differences

Cellophane bags offer superior clarity and a glossy, natural appearance that enhances product visibility, making them ideal for showcasing fresh foods and decorative items. LDPE bags provide a more opaque, matte finish, which can obscure the contents and are better suited for products needing a moisture barrier or less visual emphasis. The transparent quality of cellophane creates a premium, aesthetically pleasing presentation compared to the practical, functional look of LDPE bags.

Moisture and Barrier Properties

Cellophane bags offer superior moisture resistance and oxygen barrier properties compared to LDPE bags, making them ideal for packaging products that require extended freshness and protection from humidity. LDPE bags exhibit higher moisture vapor permeability, which can lead to faster product spoilage in high-humidity environments. The natural cellulose structure of cellophane provides better gas and moisture barrier performance, enhancing shelf life for food and pharmaceutical packaging.

Food Safety and Regulatory Compliance

Cellophane bags, made from regenerated cellulose, offer superior breathability and biodegradability, making them an excellent choice for food packaging with a natural barrier against moisture and gases. LDPE bags, derived from low-density polyethylene, provide strong chemical resistance and moisture protection but may rely on additives that require strict regulatory compliance under FDA and EU food contact material standards. Both materials must meet food safety regulations; however, cellophane's compostable nature aligns well with increasing regulatory emphasis on sustainable packaging in the food industry.

Cost Analysis: Cellophane vs LDPE Bags

Cellophane bags generally incur higher production costs due to the natural cellulose material and energy-intensive manufacturing process, unlike LDPE bags made from inexpensive polyethylene resin. LDPE bags benefit from lower raw material prices and efficient mass production techniques, resulting in a significantly lower cost per unit. When evaluating packaging expenses, LDPE bags offer a more budget-friendly option, especially for large-scale operations requiring durable and moisture-resistant packaging.

Common Applications and Uses

Cellophane bags, made from regenerated cellulose, are commonly used for food packaging, floral wraps, and gift bags due to their transparency, moisture resistance, and biodegradable nature, making them ideal for eco-friendly packaging solutions. LDPE bags, crafted from low-density polyethylene, are widely utilized for grocery bags, produce packaging, and industrial liners because of their durability, flexibility, and resistance to chemicals and moisture. While cellophane bags excel in applications requiring biodegradability and aesthetic appeal, LDPE bags are preferred for heavy-duty and everyday utility purposes.

Choosing the Right Bag: Key Considerations

Cellophane bags offer superior biodegradability and a clear, glossy appearance, making them ideal for eco-conscious packaging and product visibility. LDPE bags provide greater flexibility, durability, and moisture resistance, suitable for heavy-duty storage and prolonged shelf life. Key considerations include environmental impact, product protection needs, and customer presentation preferences.

Cellophane Bags vs LDPE Bags Infographic

materialdif.com

materialdif.com