Cellophane tape offers superior transparency and is biodegradable, making it an eco-friendly choice compared to plastic tape, which is typically made from non-biodegradable polyethylene or polypropylene. Cellophane tape adheres well to paper and light packaging but has limited resistance to moisture and temperature changes, whereas plastic tape provides stronger durability and water resistance suitable for heavy-duty applications. Choosing between cellophane and plastic tape depends on the balance between environmental impact, adhesive strength, and intended use.

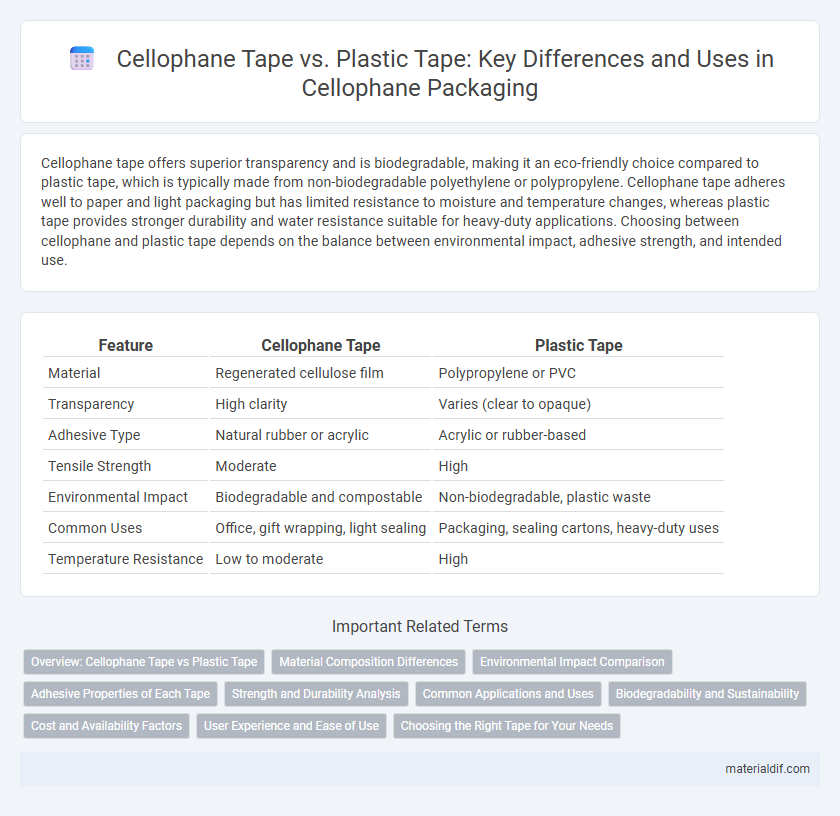

Table of Comparison

| Feature | Cellophane Tape | Plastic Tape |

|---|---|---|

| Material | Regenerated cellulose film | Polypropylene or PVC |

| Transparency | High clarity | Varies (clear to opaque) |

| Adhesive Type | Natural rubber or acrylic | Acrylic or rubber-based |

| Tensile Strength | Moderate | High |

| Environmental Impact | Biodegradable and compostable | Non-biodegradable, plastic waste |

| Common Uses | Office, gift wrapping, light sealing | Packaging, sealing cartons, heavy-duty uses |

| Temperature Resistance | Low to moderate | High |

Overview: Cellophane Tape vs Plastic Tape

Cellophane tape, made from cellulose film, offers excellent transparency and biodegradability, making it an eco-friendly choice for light-duty sealing and packaging. Plastic tape, often crafted from polypropylene or vinyl, provides superior strength, moisture resistance, and durability, ideal for heavy-duty applications and prolonged use. The key differences lie in their material composition, environmental impact, and performance characteristics.

Material Composition Differences

Cellophane tape is made from cellulose, a natural polymer derived from wood pulp or cotton fibers, which makes it biodegradable and more environmentally friendly compared to plastic tape. Plastic tape, often composed of polypropylene or PVC, consists of synthetic polymers that provide greater tensile strength and resistance to moisture but contribute to long-term environmental pollution. The material composition differences impact their adhesive properties, durability, and ecological footprints, influencing applications in packaging, labeling, and household uses.

Environmental Impact Comparison

Cellophane tape is biodegradable, made from cellulose derived from wood pulp, which decomposes naturally without releasing harmful microplastics. Plastic tape, typically composed of polypropylene or PVC, persists in the environment for hundreds of years, contributing to plastic pollution and harming wildlife. Choosing cellophane tape significantly reduces environmental footprint by supporting sustainable materials and minimizing landfill waste.

Adhesive Properties of Each Tape

Cellophane tape features a natural, water-based adhesive that provides moderate tackiness and easier removability, making it ideal for lightweight packaging and general office use. Plastic tape typically uses a synthetic, rubber-based adhesive with stronger adhesion and enhanced resistance to moisture and temperature, ensuring a more durable and long-lasting bond on various surfaces. The difference in adhesive composition directly impacts their suitability for different applications, with plastic tape preferred for heavy-duty tasks and cellophane tape favored for temporary fixes.

Strength and Durability Analysis

Cellophane tape offers moderate strength suitable for lightweight packaging and general use, while plastic tape, often made from polypropylene or PVC, provides superior tensile strength and resistance to tearing. Durability tests reveal plastic tape maintains adhesion and integrity under extreme temperature variations and moisture exposure better than cellophane tape, making it ideal for heavy-duty sealing. The elasticity and chemical resistance of plastic tape contribute to its prolonged performance, whereas cellophane tape tends to degrade faster under stress and environmental factors.

Common Applications and Uses

Cellophane tape is widely used for light-duty tasks such as sealing envelopes, gift wrapping, and office paper repairs due to its transparency and ease of tearing by hand. Plastic tape, including polypropylene and PVC variants, offers stronger adhesion and moisture resistance, making it suitable for packaging heavy boxes, bundling items, and industrial applications. Both tapes serve distinct roles, with cellophane tape favored for everyday household and office uses, while plastic tape excels in robust, commercial packaging scenarios.

Biodegradability and Sustainability

Cellophane tape, derived from cellulose, is biodegradable and biodegradable within a few weeks under composting conditions, making it a sustainable option compared to plastic tape. Plastic tape, commonly made from polypropylene or PVC, is non-biodegradable and contributes significantly to long-term environmental pollution and landfill waste. Choosing cellophane tape supports eco-friendly packaging solutions due to its renewable material base and ability to break down naturally.

Cost and Availability Factors

Cellophane tape is generally more affordable than plastic tape due to its biodegradable cellulose base, making it a cost-effective option for everyday use. Widely available in office supply stores and supermarkets, cellophane tape meets the demand for eco-friendly alternatives without compromising availability. Plastic tape, though sometimes more durable, often comes at a higher price and can be less accessible in regions prioritizing sustainable products.

User Experience and Ease of Use

Cellophane tape offers a smooth application with minimal residue, enhancing user experience through its easy tearability and reliable adhesion on various surfaces. In contrast, plastic tape tends to be stickier and harder to tear by hand, often requiring scissors or dispensers, which can complicate use. The lightweight, transparent nature of cellophane tape also provides a cleaner aesthetic, making it preferred for gift wrapping and office tasks.

Choosing the Right Tape for Your Needs

Cellophane tape offers superior biodegradability and a non-yellowing finish, making it ideal for archival or environmentally conscious projects, while plastic tape provides enhanced strength and moisture resistance suited for heavy-duty packaging. Selecting the right tape depends on factors such as surface type, exposure to humidity, and desired durability; for lightweight or temporary tasks, cellophane tape suffices, whereas plastic tape excels in securing heavy parcels or outdoor applications. Evaluating these properties ensures optimal adhesive performance tailored to your specific requirements.

Cellophane Tape vs Plastic Tape Infographic

materialdif.com

materialdif.com