UV-treated cellophane offers enhanced protection against ultraviolet rays, making it ideal for preserving products sensitive to light exposure. Standard cellophane lacks this UV-resistant property, which can lead to faster degradation and reduced shelf life in items exposed to sunlight. Choosing UV-treated cellophane extends product freshness and maintains visual appeal by minimizing fading and damage.

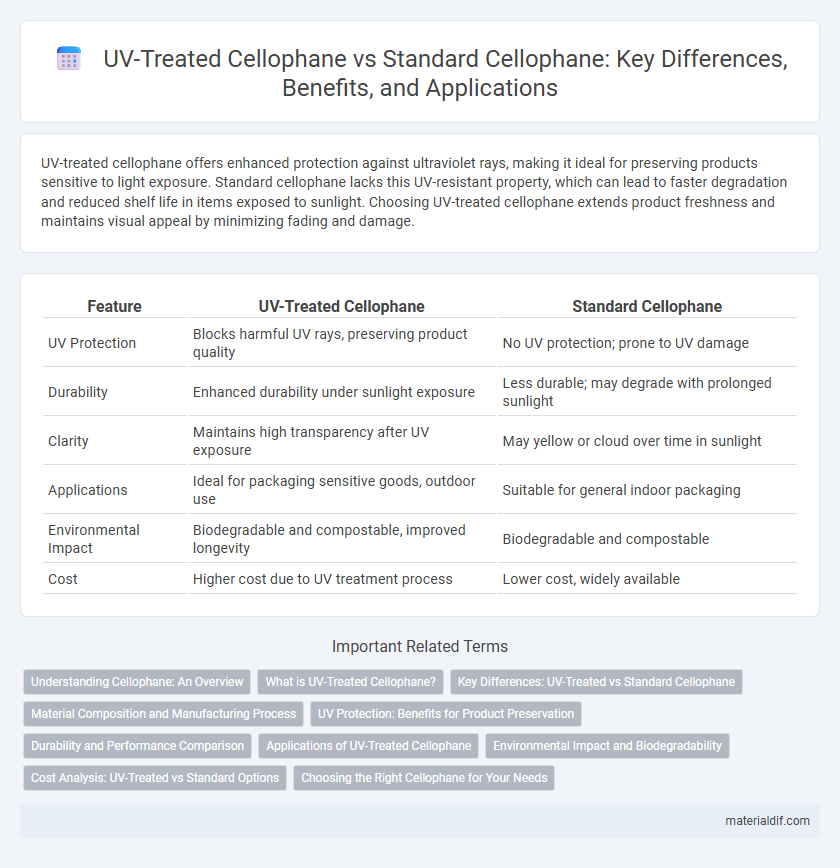

Table of Comparison

| Feature | UV-Treated Cellophane | Standard Cellophane |

|---|---|---|

| UV Protection | Blocks harmful UV rays, preserving product quality | No UV protection; prone to UV damage |

| Durability | Enhanced durability under sunlight exposure | Less durable; may degrade with prolonged sunlight |

| Clarity | Maintains high transparency after UV exposure | May yellow or cloud over time in sunlight |

| Applications | Ideal for packaging sensitive goods, outdoor use | Suitable for general indoor packaging |

| Environmental Impact | Biodegradable and compostable, improved longevity | Biodegradable and compostable |

| Cost | Higher cost due to UV treatment process | Lower cost, widely available |

Understanding Cellophane: An Overview

UV-treated cellophane enhances the standard cellophane by incorporating ultraviolet protection, which significantly improves the material's resistance to UV light degradation, extending its durability and clarity. Standard cellophane, derived from cellulose, offers excellent biodegradability and moisture resistance but lacks specialized UV protection, making it prone to yellowing and brittleness when exposed to sunlight. Understanding these differences is crucial for applications requiring extended product shelf life, such as food packaging and delicate item wraps.

What is UV-Treated Cellophane?

UV-treated cellophane is a specially coated form of cellophane designed to block ultraviolet (UV) rays, enhancing the protection of packaged goods from sunlight-induced damage. This treatment helps preserve the color, flavor, and overall quality of products like food and flowers by preventing UV-related degradation. Compared to standard cellophane, UV-treated cellophane provides superior barrier properties against UV radiation while maintaining biodegradability and clarity.

Key Differences: UV-Treated vs Standard Cellophane

UV-treated cellophane features a specialized coating that enhances its resistance to ultraviolet light, significantly extending the durability of packaged goods compared to standard cellophane. Standard cellophane, while biodegradable and breathable, lacks UV protection, making it less suitable for products sensitive to light degradation. The UV-treated variant preserves color, taste, and nutritional value by preventing UV-induced deterioration, making it ideal for food packaging and sensitive materials.

Material Composition and Manufacturing Process

UV-treated cellophane is manufactured by incorporating UV-blocking agents or coatings during the production process, enhancing its ability to filter harmful ultraviolet rays compared to standard cellophane. While standard cellophane is primarily composed of cellulose derived from wood pulp, UV-treated variants undergo additional chemical treatments or lamination with UV-resistant materials to improve durability and protection. This specialized manufacturing process results in a product ideal for preserving light-sensitive goods, offering superior UV resistance without compromising the biodegradable nature of cellulose-based cellophane.

UV Protection: Benefits for Product Preservation

UV-treated cellophane offers superior protection against ultraviolet rays, significantly extending the shelf life of sensitive products such as food, cosmetics, and pharmaceuticals. Unlike standard cellophane, which provides limited UV blocking, UV-treated variants prevent discoloration, degradation, and nutrient loss caused by exposure to sunlight. This enhanced UV protection helps maintain product quality, appearance, and safety, making it an ideal choice for packaging applications where preservation is critical.

Durability and Performance Comparison

UV-treated cellophane offers enhanced durability compared to standard cellophane, providing superior resistance to ultraviolet radiation, which prevents brittleness and discoloration over time. This treatment extends the film's lifespan in outdoor or high-exposure applications, maintaining clarity and strength under harsh environmental conditions. Standard cellophane, lacking UV protection, tends to degrade faster, resulting in reduced performance and shorter usability in UV-intensive settings.

Applications of UV-Treated Cellophane

UV-treated cellophane offers enhanced protection against ultraviolet rays, making it ideal for preserving perishables such as fruits, vegetables, and baked goods by extending shelf life and maintaining freshness. Its ability to block UV light prevents product degradation, discoloration, and nutrient loss, which is crucial in food packaging, pharmaceuticals, and cosmetics industries. This specialized cellophane is also used for sensitive electronic components and artworks to shield them from UV-induced damage while allowing clear visibility.

Environmental Impact and Biodegradability

UV-treated cellophane offers enhanced protection against ultraviolet degradation, extending the lifespan of packaging and reducing material waste compared to standard cellophane. Both UV-treated and standard cellophane are biodegradable, but UV-treated variants may have additives that slightly alter biodegradability rates, though they remain environmentally friendly alternatives to synthetic plastics. Choosing UV-treated cellophane balances performance with eco-conscious disposal, supporting sustainable packaging initiatives.

Cost Analysis: UV-Treated vs Standard Options

UV-treated cellophane typically incurs higher production costs due to specialized coatings that enhance UV protection, resulting in a price increase of 15-25% compared to standard cellophane. Despite the initial cost premium, UV-treated cellophane extends product shelf life by preventing UV-induced degradation, potentially reducing losses and replacement expenses in packaging applications. Industrial buyers must evaluate cost-benefit trade-offs, considering long-term savings from improved durability against upfront material costs.

Choosing the Right Cellophane for Your Needs

UV-treated cellophane offers enhanced protection against ultraviolet light, making it ideal for preserving the freshness and appearance of products sensitive to UV damage, such as food and cosmetics. Standard cellophane provides basic moisture resistance and clarity but lacks the added UV-blocking properties, making it suitable for general packaging needs where UV exposure is minimal. Selecting the right cellophane depends on evaluating product sensitivity to UV light, desired shelf life, and the level of protection required to maintain quality during storage and display.

UV-Treated Cellophane vs Standard Cellophane Infographic

materialdif.com

materialdif.com