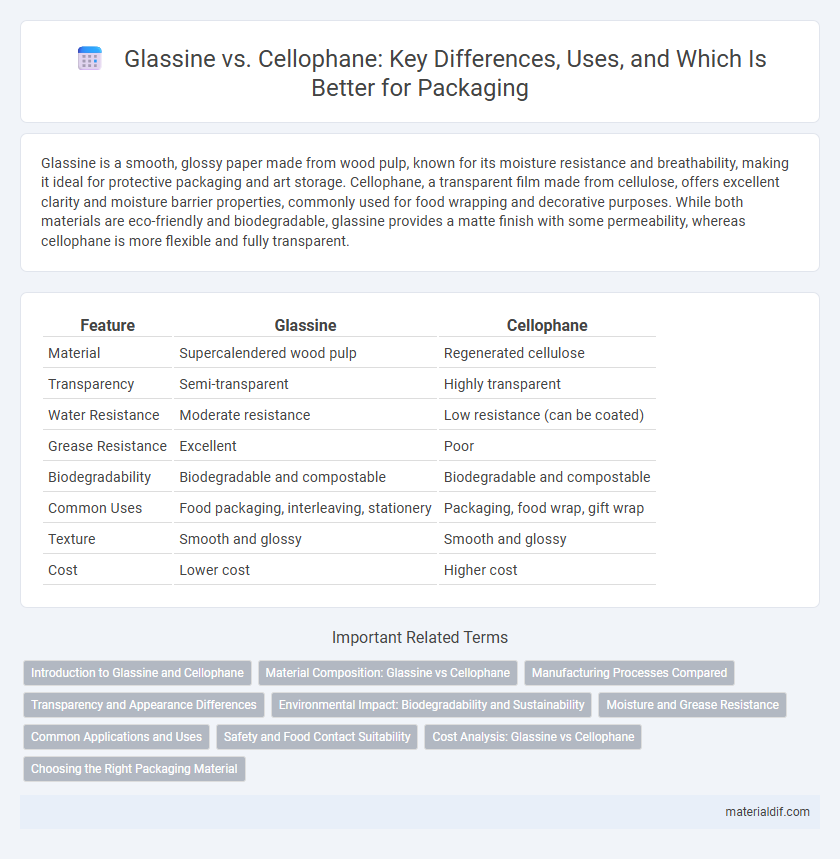

Glassine is a smooth, glossy paper made from wood pulp, known for its moisture resistance and breathability, making it ideal for protective packaging and art storage. Cellophane, a transparent film made from cellulose, offers excellent clarity and moisture barrier properties, commonly used for food wrapping and decorative purposes. While both materials are eco-friendly and biodegradable, glassine provides a matte finish with some permeability, whereas cellophane is more flexible and fully transparent.

Table of Comparison

| Feature | Glassine | Cellophane |

|---|---|---|

| Material | Supercalendered wood pulp | Regenerated cellulose |

| Transparency | Semi-transparent | Highly transparent |

| Water Resistance | Moderate resistance | Low resistance (can be coated) |

| Grease Resistance | Excellent | Poor |

| Biodegradability | Biodegradable and compostable | Biodegradable and compostable |

| Common Uses | Food packaging, interleaving, stationery | Packaging, food wrap, gift wrap |

| Texture | Smooth and glossy | Smooth and glossy |

| Cost | Lower cost | Higher cost |

Introduction to Glassine and Cellophane

Glassine is a smooth, glossy, and translucent paper known for its resistance to air, water, and grease, making it ideal for packaging and protecting delicate items. Cellophane, a transparent film made from cellulose, is widely used for wrapping due to its excellent moisture barrier and clarity. Both materials serve as eco-friendly alternatives in packaging, with Glassine offering superior breathability and Cellophane providing better moisture resistance.

Material Composition: Glassine vs Cellophane

Glassine is made from highly processed wood pulp that undergoes a supercalendering process to achieve its smooth, glossy, and translucent surface, while cellophane is produced from regenerated cellulose derived mainly from wood, cotton, or hemp fibers. The supercalendering in glassine compacts the fibers tightly, resulting in a grease-resistant and moisture-resistant paper, in contrast to cellophane's thin, flexible film that offers excellent clarity and moisture barrier properties due to its cellulose-based film structure. Both materials are biodegradable but differ significantly in texture and performance due to these variations in material composition and manufacturing processes.

Manufacturing Processes Compared

Glassine is produced by supercalendering paper to create a smooth, glossy, and translucent finish, while cellophane undergoes a viscose process involving cellulose extraction and regeneration into thin, transparent films. Cellophane manufacturing involves cellulose treated with chemicals such as sodium hydroxide and carbon disulfide, followed by extrusion and washing, resulting in a biodegradable, moisture-resistant film. Glassine's simpler paper-based process makes it more opaque and less moisture resistant compared to cellophane, which excels in clarity and barrier properties due to its biopolymer origins.

Transparency and Appearance Differences

Glassine offers a smooth, glossy surface with high transparency, making it ideal for showcasing products while providing a semi-water-resistant barrier. Cellophane typically presents a crisper, more rigid texture with excellent clarity but less gloss, enhancing the visual appeal of fresh food packaging. Differences in appearance stem from glassine's paper-like finish versus cellophane's plastic-like transparency, influencing consumer perception and packaging suitability.

Environmental Impact: Biodegradability and Sustainability

Glassine, made from tightly packed cellulose fibers, is fully biodegradable and often sourced from sustainably managed forests, making it an eco-friendly choice for packaging. In contrast, traditional cellophane, derived from cellulose but chemically treated with plasticizers and coatings, may degrade more slowly and pose challenges in composting and recycling processes. Both materials offer sustainability benefits over conventional plastics, but glassine's natural composition enhances its environmental impact through easier biodegradability and reduced chemical additives.

Moisture and Grease Resistance

Glassine offers superior grease resistance due to its tightly packed fibers and smooth surface, making it ideal for packaging oily or greasy products. Cellophane provides excellent moisture resistance as it is made from regenerated cellulose film, effectively protecting contents from humidity. Both materials serve distinct protective functions, with glassine excelling in grease barriers and cellophane in moisture barriers.

Common Applications and Uses

Glassine is commonly used for food wrapping, archival paper protection, and as interleaving sheets due to its smooth, grease-resistant, and translucent properties. Cellophane is widely applied in packaging for fresh produce, confectionery, and gift wrapping because of its high clarity, moisture resistance, and biodegradability. Both materials serve important roles in preserving product freshness and enhancing visual appeal in various consumer goods.

Safety and Food Contact Suitability

Glassine offers excellent grease resistance and is FDA-approved for direct food contact, making it highly safe for packaging sensitive food items. Cellophane is biodegradable and moisture-resistant but may require a coating to meet food safety standards, affecting its environmental impact. Both materials provide distinct advantages in food packaging, with glassine favored for safety compliance and cellophane for eco-friendliness.

Cost Analysis: Glassine vs Cellophane

Glassine is generally more expensive than cellophane due to its manufacturing process, which involves supercalendering to create a smooth, glossy, and grease-resistant surface. Cellophane offers a cost-effective alternative, providing good moisture and air barrier properties at a lower price point, making it suitable for mass packaging applications. When choosing between the two, businesses often weigh the premium cost of glassine against the affordability and adequate protective qualities of cellophane.

Choosing the Right Packaging Material

Glassine offers a smooth, glossy finish with excellent grease resistance, making it ideal for moisture-sensitive products, while cellophane provides superior breathability and biodegradability, suitable for fresh food packaging. Selecting the right packaging material depends on product requirements such as clarity, barrier properties, and environmental impact. Brands prioritizing sustainability often prefer cellophane for its compostable nature, whereas glassine is favored for its strength and protective qualities in specialty packaging.

Glassine vs Cellophane Infographic

materialdif.com

materialdif.com