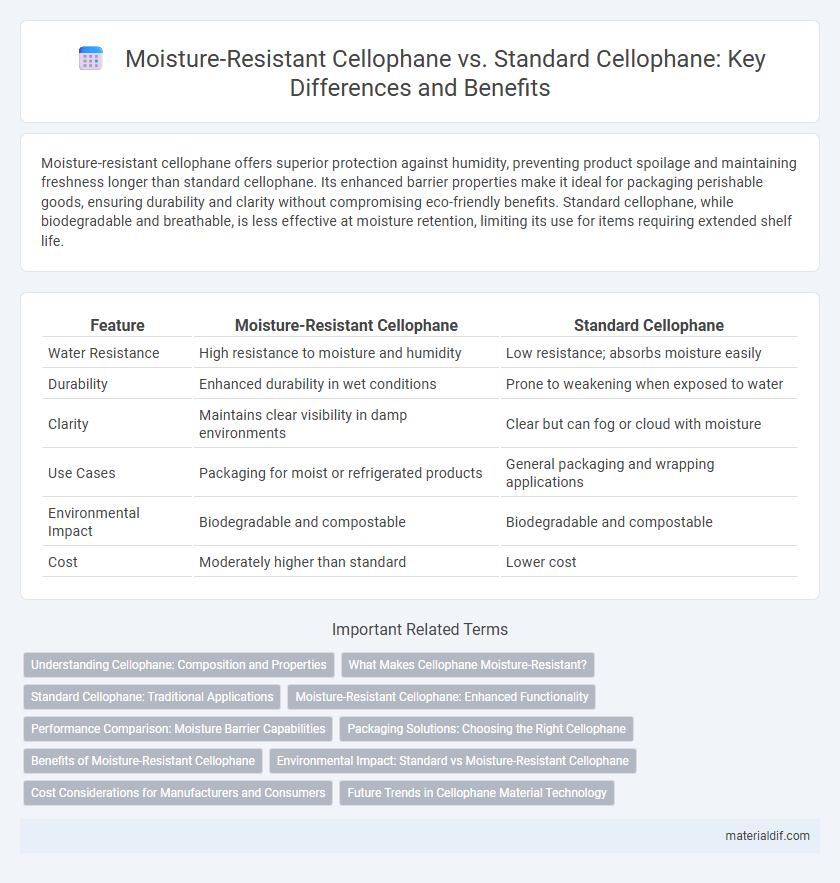

Moisture-resistant cellophane offers superior protection against humidity, preventing product spoilage and maintaining freshness longer than standard cellophane. Its enhanced barrier properties make it ideal for packaging perishable goods, ensuring durability and clarity without compromising eco-friendly benefits. Standard cellophane, while biodegradable and breathable, is less effective at moisture retention, limiting its use for items requiring extended shelf life.

Table of Comparison

| Feature | Moisture-Resistant Cellophane | Standard Cellophane |

|---|---|---|

| Water Resistance | High resistance to moisture and humidity | Low resistance; absorbs moisture easily |

| Durability | Enhanced durability in wet conditions | Prone to weakening when exposed to water |

| Clarity | Maintains clear visibility in damp environments | Clear but can fog or cloud with moisture |

| Use Cases | Packaging for moist or refrigerated products | General packaging and wrapping applications |

| Environmental Impact | Biodegradable and compostable | Biodegradable and compostable |

| Cost | Moderately higher than standard | Lower cost |

Understanding Cellophane: Composition and Properties

Moisture-resistant cellophane is specially treated with coatings or additives to significantly reduce water vapor permeability, enhancing its protective qualities compared to standard cellophane. Both types are made from regenerated cellulose derived from wood pulp or cotton linters, but the moisture-resistant variant undergoes additional chemical modifications to improve barrier properties against humidity. Understanding the cellulose structure and film coatings is crucial for selecting the right cellophane material for packaging applications requiring moisture protection.

What Makes Cellophane Moisture-Resistant?

Moisture-resistant cellophane is treated with a thin coating of resins or waxes that create a water-repellent barrier, preventing moisture from penetrating the material. Unlike standard cellophane, which is naturally hydrophilic due to its cellulose base, moisture-resistant versions combine this cellulose film with specialized polymers to enhance water resistance. This modification preserves the cellophane's clarity and biodegradability while significantly improving its suitability for packaging products sensitive to humidity.

Standard Cellophane: Traditional Applications

Standard cellophane is widely used in packaging for food products such as candies, baked goods, and fresh produce due to its clarity, biodegradability, and ability to provide a basic moisture barrier. It offers breathability that helps maintain the freshness of items prone to spoilage from excess moisture accumulation. Common applications also include gift wrapping and flower packaging where its transparent, glossy finish enhances visual appeal without requiring specialized moisture resistance.

Moisture-Resistant Cellophane: Enhanced Functionality

Moisture-resistant cellophane offers superior barrier properties compared to standard cellophane, effectively preventing water vapor penetration and extending product shelf life. This enhanced functionality makes it ideal for packaging perishable goods such as food and pharmaceuticals where moisture control is critical. Its robust resistance to humidity maintains product integrity and reduces spoilage, ensuring higher quality preservation.

Performance Comparison: Moisture Barrier Capabilities

Moisture-resistant cellophane offers superior barrier capabilities, reducing water vapor transmission rates significantly compared to standard cellophane, enhancing product shelf life and integrity. Standard cellophane, made from regenerated cellulose, has moderate moisture permeability, making it less effective for packaging items sensitive to humidity. The advanced coating or lamination in moisture-resistant cellophane improves its performance, maintaining dryness and preventing spoilage in various industrial and food packaging applications.

Packaging Solutions: Choosing the Right Cellophane

Moisture-resistant cellophane offers superior barrier properties that protect products from humidity, making it ideal for packaging items sensitive to moisture such as food, pharmaceuticals, and electronics. Standard cellophane provides breathability and biodegradability but lacks the enhanced moisture protection required for extended shelf life and freshness. Selecting the right cellophane depends on evaluating product sensitivity, desired shelf life, and environmental impact to ensure optimal packaging performance.

Benefits of Moisture-Resistant Cellophane

Moisture-resistant cellophane offers superior protection against humidity, significantly extending the shelf life of perishable goods compared to standard cellophane. Its enhanced barrier properties prevent moisture penetration, maintaining product freshness and preventing spoilage. This makes moisture-resistant cellophane ideal for packaging food items, pharmaceuticals, and other moisture-sensitive products.

Environmental Impact: Standard vs Moisture-Resistant Cellophane

Moisture-resistant cellophane offers enhanced barrier properties that reduce product spoilage and waste, contributing to a lower overall environmental footprint compared to standard cellophane. While standard cellophane is biodegradable and compostable due to its cellulose base, the coatings used in moisture-resistant varieties can slow down degradation and complicate recycling processes. Choosing moisture-resistant cellophane with environmentally friendly coatings helps balance performance needs with sustainability goals.

Cost Considerations for Manufacturers and Consumers

Moisture-resistant cellophane typically incurs higher production costs due to specialized coatings or treatments, impacting pricing for manufacturers and consumers. Standard cellophane remains more economical but lacks enhanced barrier properties, leading to potential product spoilage and increased waste. Manufacturers weigh initial material costs against long-term benefits like extended shelf life when choosing between moisture-resistant and standard options.

Future Trends in Cellophane Material Technology

Moisture-resistant cellophane is evolving through innovations in biodegradable coatings that enhance barrier properties without compromising environmental sustainability. Research on nanocomposite laminates and bio-based additives is driving improved water vapor resistance and mechanical strength in cellophane films. Future trends highlight increased adoption of eco-friendly, high-performance cellophane materials tailored for packaging sectors prioritizing durability and reduced moisture permeability.

Moisture-Resistant Cellophane vs Standard Cellophane Infographic

materialdif.com

materialdif.com