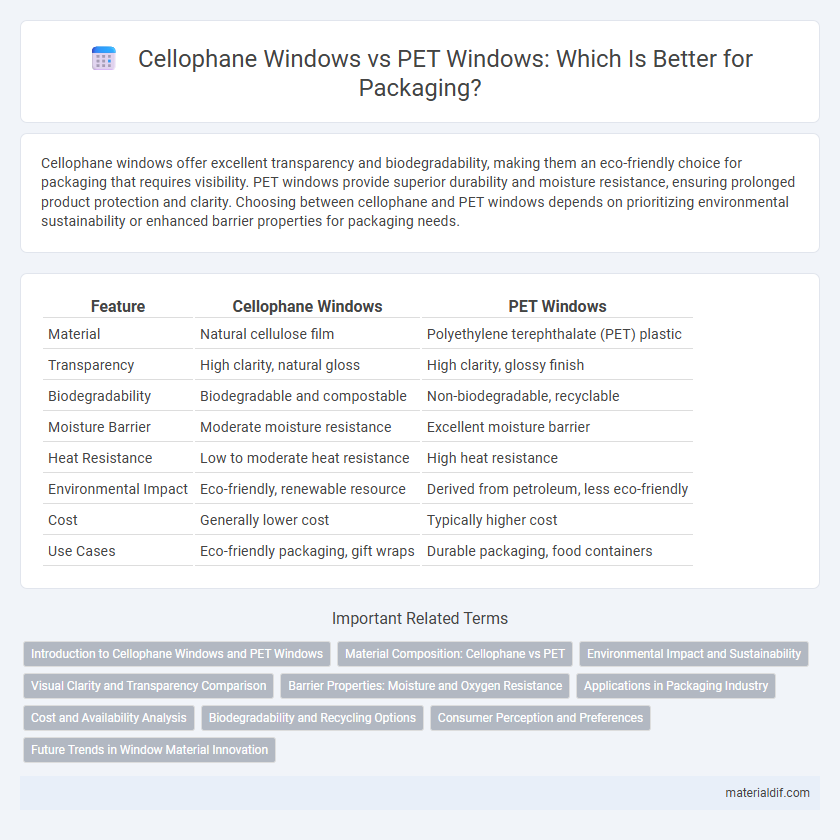

Cellophane windows offer excellent transparency and biodegradability, making them an eco-friendly choice for packaging that requires visibility. PET windows provide superior durability and moisture resistance, ensuring prolonged product protection and clarity. Choosing between cellophane and PET windows depends on prioritizing environmental sustainability or enhanced barrier properties for packaging needs.

Table of Comparison

| Feature | Cellophane Windows | PET Windows |

|---|---|---|

| Material | Natural cellulose film | Polyethylene terephthalate (PET) plastic |

| Transparency | High clarity, natural gloss | High clarity, glossy finish |

| Biodegradability | Biodegradable and compostable | Non-biodegradable, recyclable |

| Moisture Barrier | Moderate moisture resistance | Excellent moisture barrier |

| Heat Resistance | Low to moderate heat resistance | High heat resistance |

| Environmental Impact | Eco-friendly, renewable resource | Derived from petroleum, less eco-friendly |

| Cost | Generally lower cost | Typically higher cost |

| Use Cases | Eco-friendly packaging, gift wraps | Durable packaging, food containers |

Introduction to Cellophane Windows and PET Windows

Cellophane windows are biodegradable, made from regenerated cellulose, offering excellent transparency and breathability for eco-friendly packaging. PET windows, crafted from polyethylene terephthalate, provide superior durability, moisture resistance, and clarity, making them ideal for long-lasting product visibility. Both options enhance product presentation but cater to different sustainability and performance requirements in packaging.

Material Composition: Cellophane vs PET

Cellophane windows are made from regenerated cellulose derived from wood pulp, offering biodegradability and compostability, unlike PET windows composed of polyethylene terephthalate, a petroleum-based plastic known for its durability and resistance to moisture. Cellophane's natural polymer structure allows for breathability and eco-friendly disposal, whereas PET's synthetic polymer chains provide superior strength and clarity but contribute to environmental persistence. Choosing between cellophane and PET windows involves weighing the benefits of sustainable material composition against long-lasting performance in packaging applications.

Environmental Impact and Sustainability

Cellophane windows are biodegradable and derived from cellulose, making them a more environmentally friendly option compared to PET windows, which are made from non-biodegradable petroleum-based plastics. The production of cellophane involves renewable resources and results in lower carbon emissions, contributing to reduced environmental impact. PET windows, although durable and recyclable, often end up in landfills due to insufficient recycling infrastructure, raising concerns about long-term sustainability.

Visual Clarity and Transparency Comparison

Cellophane windows provide exceptional visual clarity due to their natural cellulose composition, offering high transparency with minimal glare and a matte finish. PET windows, made from polyethylene terephthalate, deliver superior durability and a glossy surface but may exhibit slight haze or reflections that affect visual clarity. For applications prioritizing crisp, clear visibility with a natural look, cellophane windows outperform PET in transparency and optical quality.

Barrier Properties: Moisture and Oxygen Resistance

Cellophane windows offer moderate moisture resistance but have limited oxygen barrier properties, making them less effective for packaging sensitive products. PET windows provide superior moisture and oxygen resistance due to their dense polymer structure, enhancing shelf life and product preservation. The higher barrier performance of PET windows is preferred in applications requiring extended freshness and protection against external contaminants.

Applications in Packaging Industry

Cellophane windows offer biodegradable and oxygen-resistant properties, making them ideal for eco-friendly packaging of fresh produce and bakery items. PET windows provide superior clarity, durability, and moisture barrier, commonly used in food packaging requiring high visibility and extended shelf life such as confectionery and ready-to-eat meals. The choice between cellophane and PET windows depends on the balance between environmental considerations and performance requirements in the packaging industry.

Cost and Availability Analysis

Cellophane windows typically cost less than PET windows due to the lower material and manufacturing expenses associated with cellophane. Availability of cellophane windows is generally higher, as cellophane is widely produced and sourced, while PET windows may face supply constraints due to higher demand in packaging industries. Cost-effectiveness combined with broader availability makes cellophane windows a preferred choice for budget-conscious packaging solutions.

Biodegradability and Recycling Options

Cellophane windows are biodegradable, made from natural cellulose, making them an eco-friendly alternative to PET windows, which are derived from non-renewable petroleum sources and are not biodegradable. Recycling options for cellophane are limited as it requires specialized composting facilities, whereas PET windows have established recycling streams but contribute to microplastic pollution if not properly managed. Choosing cellophane windows supports sustainability in packaging through biodegradability, while PET windows offer better recycling infrastructure but pose environmental challenges due to slow decomposition.

Consumer Perception and Preferences

Consumers often perceive cellophane windows as more eco-friendly and biodegradable compared to PET windows, enhancing product appeal among environmentally conscious buyers. PET windows, known for their durability and clarity, tend to be preferred for packaging that requires a sharper display and longer shelf life. Preference trends indicate a growing demand for sustainable packaging, where cellophane's compostable properties outweigh PET's performance advantages for many consumers.

Future Trends in Window Material Innovation

Cellophane windows offer biodegradability and renewable sourcing, aligning with increasing demand for sustainable packaging materials. PET windows, known for durability and moisture resistance, are evolving with advanced recycling technologies to reduce environmental impact. Future trends indicate a shift towards hybrid materials that combine biodegradability and performance, driven by regulatory pressures and consumer preference for eco-friendly packaging solutions.

Cellophane Windows vs PET Windows Infographic

materialdif.com

materialdif.com