Cellophane and compostable film are both eco-friendly packaging materials, but they differ significantly in composition and biodegradability. Cellophane is made from regenerated cellulose derived from wood pulp, making it biodegradable and compostable under industrial conditions. Compostable films, typically made from plant-based polymers like PLA or starch blends, break down more rapidly in home compost environments and offer a renewable alternative to traditional plastics.

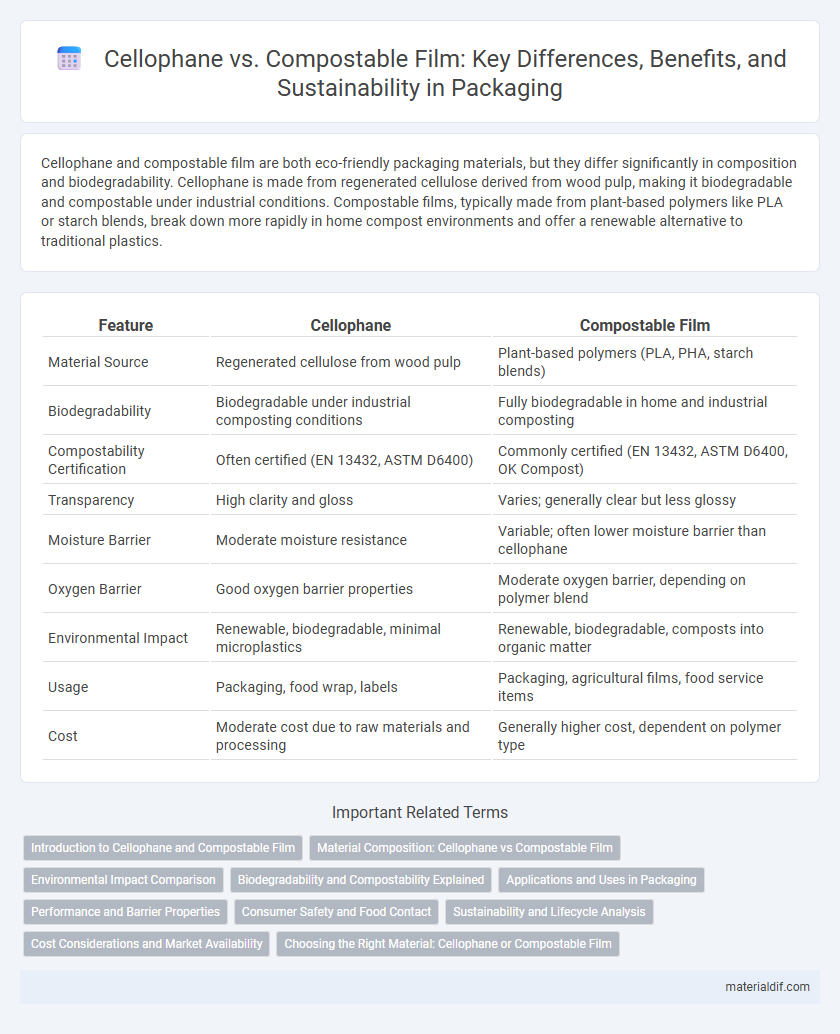

Table of Comparison

| Feature | Cellophane | Compostable Film |

|---|---|---|

| Material Source | Regenerated cellulose from wood pulp | Plant-based polymers (PLA, PHA, starch blends) |

| Biodegradability | Biodegradable under industrial composting conditions | Fully biodegradable in home and industrial composting |

| Compostability Certification | Often certified (EN 13432, ASTM D6400) | Commonly certified (EN 13432, ASTM D6400, OK Compost) |

| Transparency | High clarity and gloss | Varies; generally clear but less glossy |

| Moisture Barrier | Moderate moisture resistance | Variable; often lower moisture barrier than cellophane |

| Oxygen Barrier | Good oxygen barrier properties | Moderate oxygen barrier, depending on polymer blend |

| Environmental Impact | Renewable, biodegradable, minimal microplastics | Renewable, biodegradable, composts into organic matter |

| Usage | Packaging, food wrap, labels | Packaging, agricultural films, food service items |

| Cost | Moderate cost due to raw materials and processing | Generally higher cost, dependent on polymer type |

Introduction to Cellophane and Compostable Film

Cellophane is a thin, transparent film made from regenerated cellulose, known for its excellent moisture and air barrier properties, commonly used in packaging for food products. Compostable films are derived from biodegradable materials like polylactic acid (PLA) or starch blends, designed to break down in industrial composting facilities within months. While cellophane offers durability and clarity, compostable films prioritize environmental sustainability by reducing plastic waste through rapid decomposition.

Material Composition: Cellophane vs Compostable Film

Cellophane is made from regenerated cellulose derived from wood pulp, offering a biodegradable and breathable film with natural origin. Compostable films are typically composed of polylactic acid (PLA), starch blends, or other bio-based polymers engineered for rapid decomposition in industrial composting conditions. The key difference lies in cellophane's pure cellulose base versus compostable films' synthetic or blended biopolymers designed for enhanced compostability standards.

Environmental Impact Comparison

Cellophane, derived from cellulose, is biodegradable and breaks down naturally in soil within weeks, reducing long-term environmental pollution. Compostable films, often made from polylactic acid (PLA), require industrial composting facilities to degrade effectively, which limits their environmental benefits in regions lacking such infrastructure. Unlike compostable films, cellophane offers a more consistently eco-friendly option as it does not rely on specialized composting conditions for decomposition.

Biodegradability and Compostability Explained

Cellophane is a biodegradable material derived from cellulose, allowing it to break down naturally in the environment without leaving harmful residues. Compostable films, often made from plant-based polymers, not only biodegrade but also meet specific standards to decompose within composting systems, producing nutrient-rich compost. While both materials offer environmentally friendly alternatives to traditional plastics, compostable films require industrial or home composting conditions to fully degrade, whereas cellophane can degrade more broadly in various natural environments.

Applications and Uses in Packaging

Cellophane offers excellent clarity, moisture resistance, and odor barrier properties, making it ideal for packaging fresh produce, bakery items, and confectionery to enhance product visibility and extend shelf life. Compostable films, derived from renewable resources like PLA or PHA, are preferred for environmentally conscious packaging applications such as food wraps, bags, and single-use packaging where biodegradability and soil compostability are critical. While cellophane excels in presentation and protection, compostable films provide sustainable alternatives that align with eco-friendly packaging regulations and circular economy goals.

Performance and Barrier Properties

Cellophane offers superior oxygen and aroma barrier properties compared to most compostable films, making it ideal for preserving food freshness and extending shelf life. Compostable films typically excel in biodegradability and environmental impact but often show higher permeability to moisture and gases, which can compromise product quality. Performance trade-offs between cellophane and compostable films depend on the specific packaging application's demand for barrier efficacy versus sustainability.

Consumer Safety and Food Contact

Cellophane, made from cellulose derived from wood pulp, offers superior consumer safety due to its natural composition and non-toxic properties, making it highly suitable for direct food contact applications. Unlike many compostable films that often contain additives or synthetic materials, cellophane is fully biodegradable and does not release harmful substances when in contact with food. Its excellent barrier properties against oxygen and moisture further ensure food freshness and protection without compromising safety standards.

Sustainability and Lifecycle Analysis

Cellophane, derived from cellulose, is biodegradable and compostable, offering a lower environmental impact compared to many petroleum-based compostable films that often include synthetic additives. Lifecycle analysis reveals cellophane's production involves fewer fossil fuel inputs and generates less greenhouse gas emissions, enhancing its sustainability credentials. Its complete biodegradability in industrial and home composting conditions supports circular economy goals more effectively than some compostable films that require specialized industrial composting facilities.

Cost Considerations and Market Availability

Cellophane typically has higher production costs compared to compostable films due to its manufacturing process involving cellulose extraction and treatment. Compostable films benefit from increasing market availability driven by growing consumer demand for eco-friendly packaging alternatives and advances in biopolymer technologies. Pricing of compostable films is becoming more competitive as supply chains mature, making them a cost-effective option for sustainable packaging solutions.

Choosing the Right Material: Cellophane or Compostable Film

Cellophane offers excellent clarity, breathability, and biodegradability, making it ideal for packaging that requires visibility and moisture resistance. Compostable films, often made from PLA or starch-based polymers, excel in industrial composting settings with faster breakdown times but may lack the durability and oxygen barrier properties of cellophane. Choosing between cellophane and compostable film depends on factors like product shelf life, environmental impact goals, and the available waste management infrastructure.

Cellophane vs Compostable Film Infographic

materialdif.com

materialdif.com