Cellophane sheets are biodegradable and offer excellent moisture resistance, making them ideal for eco-friendly packaging, while acetate sheets provide greater durability and clarity, commonly used in craft and printing applications. Cellophane has a natural, glossy finish that enhances product visibility without compromising environmental impact. Acetate sheets, being more rigid and heat-resistant, are preferred for projects requiring long-lasting transparency and structural strength.

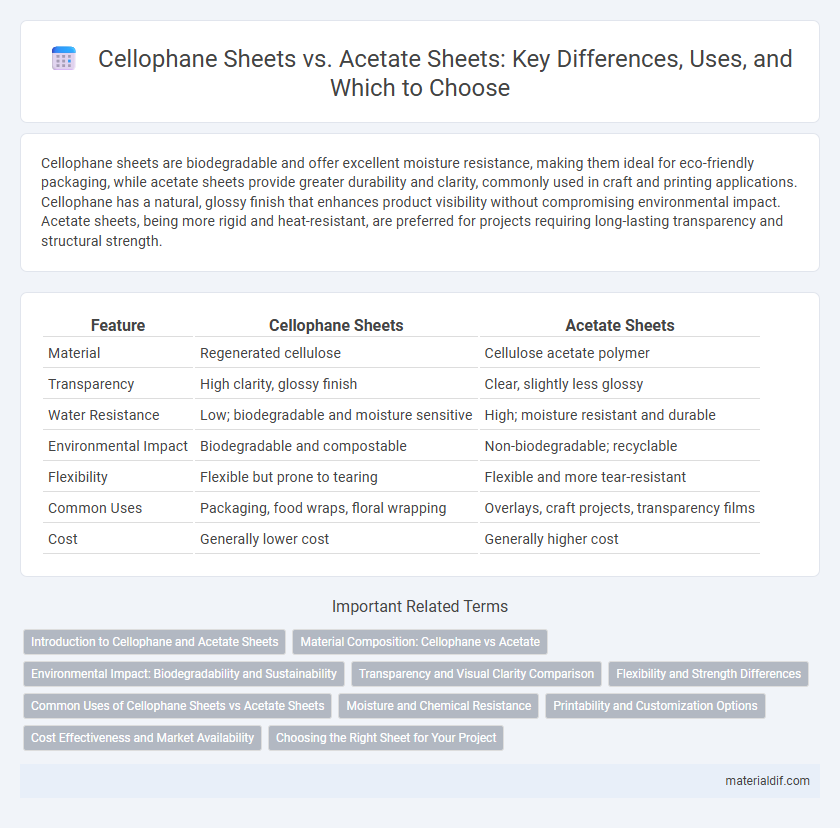

Table of Comparison

| Feature | Cellophane Sheets | Acetate Sheets |

|---|---|---|

| Material | Regenerated cellulose | Cellulose acetate polymer |

| Transparency | High clarity, glossy finish | Clear, slightly less glossy |

| Water Resistance | Low; biodegradable and moisture sensitive | High; moisture resistant and durable |

| Environmental Impact | Biodegradable and compostable | Non-biodegradable; recyclable |

| Flexibility | Flexible but prone to tearing | Flexible and more tear-resistant |

| Common Uses | Packaging, food wraps, floral wrapping | Overlays, craft projects, transparency films |

| Cost | Generally lower cost | Generally higher cost |

Introduction to Cellophane and Acetate Sheets

Cellophane sheets are thin, transparent films made from regenerated cellulose, known for their biodegradability and moisture-resistant properties, making them ideal for packaging and craft applications. Acetate sheets, derived from cellulose acetate, offer greater durability, flexibility, and clarity, often used in photographic film, overlays, and signage. Both materials serve unique purposes in industries prioritizing transparency and environmental impact, with cellophane emphasizing eco-friendliness and acetate highlighting strength and versatility.

Material Composition: Cellophane vs Acetate

Cellophane sheets are made from regenerated cellulose derived from wood pulp, making them biodegradable and breathable. Acetate sheets, however, consist of cellulose acetate, a cellulose derivative chemically modified to enhance clarity, durability, and resistance to moisture. The key difference lies in cellophane's natural cellulose base versus acetate's acetylated cellulose structure, impacting their environmental footprint and physical properties.

Environmental Impact: Biodegradability and Sustainability

Cellophane sheets, derived from cellulose, are biodegradable and decompose naturally, making them a more sustainable packaging choice compared to acetate sheets, which are made from cellulose acetate and can persist longer in the environment. The biodegradability of cellophane significantly reduces landfill waste and environmental pollution, supporting eco-friendly packaging initiatives. In contrast, acetate sheets often require industrial composting or special treatments to break down, limiting their overall environmental benefits.

Transparency and Visual Clarity Comparison

Cellophane sheets offer moderate transparency with a slightly hazy appearance, making them suitable for packaging where subtle diffusion of light is acceptable. Acetate sheets provide superior optical clarity and high transparency, delivering crystal-clear visibility that enhances the presentation of displayed items. The choice between cellophane and acetate sheets hinges on the desired level of visual sharpness and clarity for packaging or display purposes.

Flexibility and Strength Differences

Cellophane sheets exhibit lower flexibility but higher strength compared to acetate sheets, making them more resistant to tearing under stress. Acetate sheets offer greater pliability and can bend easily without cracking, ideal for applications requiring frequent handling or shaping. The cellulose-based composition of cellophane provides durability and moisture resistance, while acetate's plasticized structure enhances flexibility at the expense of tensile strength.

Common Uses of Cellophane Sheets vs Acetate Sheets

Cellophane sheets are commonly used for food packaging, gift wrapping, and as a moisture-resistant barrier in the food industry due to their biodegradable and natural cellulose composition. Acetate sheets find frequent application in overhead projector transparencies, protective covers, and craft projects because of their clarity, durability, and flexibility. The choice between cellophane and acetate sheets hinges on the specific need for biodegradability versus strength and optical clarity.

Moisture and Chemical Resistance

Cellophane sheets offer superior moisture resistance due to their natural cellulose composition, making them ideal for packaging items sensitive to humidity. Acetate sheets exhibit excellent chemical resistance, particularly against oils and solvents, which is beneficial in industrial applications requiring durability. Choosing between cellophane and acetate sheets depends on whether moisture barrier properties or chemical resistance is the primary need.

Printability and Customization Options

Cellophane sheets offer superior printability due to their natural cellulose base, which allows for vibrant, high-quality ink adhesion and a smooth, glossy finish ideal for detailed designs. Acetate sheets, while also printable, provide less vivid color reproduction and tend to require special coatings or primers for optimal ink bonding. Customization options are broader with cellophane, supporting various printing techniques such as flexography and screen printing, whereas acetate is typically limited to digital or UV printing methods.

Cost Effectiveness and Market Availability

Cellophane sheets generally offer greater cost effectiveness compared to acetate sheets due to lower manufacturing expenses and widespread raw material access. Market availability of cellophane sheets is higher, as they dominate packaging industries for their biodegradability and moisture resistance, while acetate sheets remain niche with limited suppliers primarily serving specialty uses. The balance between price and supply chain robustness makes cellophane sheets a preferred choice for large-scale production and eco-friendly packaging solutions.

Choosing the Right Sheet for Your Project

Cellophane sheets offer biodegradability and natural moisture resistance, making them ideal for eco-friendly packaging and food wrapping projects. Acetate sheets provide superior clarity, flexibility, and durability, suitable for crafts, stencils, and protective overlays that require transparency and strength. Choosing between cellophane and acetate sheets depends on project needs such as environmental impact, optical clarity, and material stiffness.

Cellophane Sheets vs Acetate Sheets Infographic

materialdif.com

materialdif.com