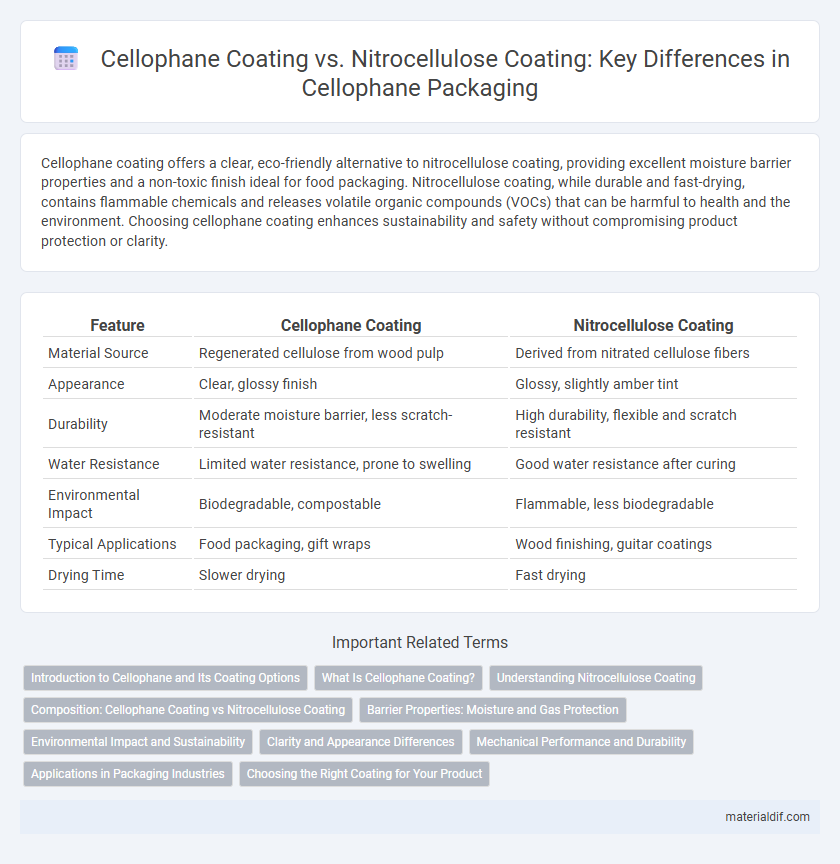

Cellophane coating offers a clear, eco-friendly alternative to nitrocellulose coating, providing excellent moisture barrier properties and a non-toxic finish ideal for food packaging. Nitrocellulose coating, while durable and fast-drying, contains flammable chemicals and releases volatile organic compounds (VOCs) that can be harmful to health and the environment. Choosing cellophane coating enhances sustainability and safety without compromising product protection or clarity.

Table of Comparison

| Feature | Cellophane Coating | Nitrocellulose Coating |

|---|---|---|

| Material Source | Regenerated cellulose from wood pulp | Derived from nitrated cellulose fibers |

| Appearance | Clear, glossy finish | Glossy, slightly amber tint |

| Durability | Moderate moisture barrier, less scratch-resistant | High durability, flexible and scratch resistant |

| Water Resistance | Limited water resistance, prone to swelling | Good water resistance after curing |

| Environmental Impact | Biodegradable, compostable | Flammable, less biodegradable |

| Typical Applications | Food packaging, gift wraps | Wood finishing, guitar coatings |

| Drying Time | Slower drying | Fast drying |

Introduction to Cellophane and Its Coating Options

Cellophane is a transparent, biodegradable film made from regenerated cellulose, widely used for packaging due to its moisture-resistant and oxygen barrier properties. Cellophane coating typically involves natural biopolymer coatings that enhance flexibility and water resistance without compromising its environmental benefits. Nitrocellulose coating, derived from cellulose treated with nitric acid, offers a hard, glossy finish with increased durability and chemical resistance but is less eco-friendly compared to cellophane's traditional coatings.

What Is Cellophane Coating?

Cellophane coating is a clear, thin, and biodegradable film derived from cellulose, primarily used for packaging to provide moisture resistance and enhance product visibility. Unlike nitrocellulose coating, which is a lacquering agent derived from nitrated cellulose used mainly for its fast-drying and durable finish on wood and metal, cellophane coating emphasizes eco-friendliness and clarity. This coating offers excellent grease resistance and acts as a natural barrier while being more environmentally sustainable than synthetic alternatives.

Understanding Nitrocellulose Coating

Nitrocellulose coating is a fast-drying, durable finish commonly used in wood and musical instruments, offering a glossy, smooth surface that enhances appearance and protection. Compared to cellophane coating, nitrocellulose forms a harder film that is more resistant to wear but can be prone to cracking and yellowing over time. This makes nitrocellulose ideal for applications requiring vintage aesthetics and high-quality finishes despite its relative sensitivity to environmental factors.

Composition: Cellophane Coating vs Nitrocellulose Coating

Cellophane coating is primarily composed of regenerated cellulose derived from wood pulp or cotton fibers, offering a biodegradable and transparent protective layer. Nitrocellulose coating consists of chemically modified cellulose nitrate dissolved in organic solvents, forming a hard, glossy finish widely used in lacquers and varnishes. The fundamental compositional difference lies in cellophane's natural polymer base compared to nitrocellulose's chemically nitrated cellulose, impacting their environmental footprint and application properties.

Barrier Properties: Moisture and Gas Protection

Cellophane coating offers superior moisture barrier properties due to its hydrophilic nature that can be enhanced with coatings, making it effective in preventing water vapor transmission. Nitrocellulose coating provides excellent gas barrier protection, particularly against oxygen, due to its dense polymer matrix but is less effective against moisture. Combining cellophane with nitrocellulose coatings can optimize packaging by delivering balanced moisture and gas protection tailored for food and pharmaceutical applications.

Environmental Impact and Sustainability

Cellophane coating is biodegradable and derived from renewable cellulose sources, making it an environmentally friendly alternative to nitrocellulose coating, which is petroleum-based and less sustainable. Nitrocellulose coatings release volatile organic compounds (VOCs) during production and application, contributing to air pollution, whereas cellophane coatings have a lower environmental footprint and break down naturally. Choosing cellophane coatings supports sustainable packaging solutions by reducing plastic waste and reliance on fossil fuels.

Clarity and Appearance Differences

Cellophane coating offers superior clarity with a smooth, glass-like finish that enhances the natural colors and textures of the underlying material, making it ideal for packaging and decorative applications. Nitrocellulose coating tends to produce a slightly hazier, more matte appearance, which can diminish visual sharpness but provides a traditional, vintage aesthetic favored in certain industries. The choice between these coatings significantly impacts product presentation, with cellophane prioritized for high-clarity needs and nitrocellulose preferred for its unique texture and historical appeal.

Mechanical Performance and Durability

Cellophane coating offers superior mechanical performance with high tensile strength and excellent flexibility, making it highly resistant to tearing and abrasion compared to nitrocellulose coating. Nitrocellulose coatings provide moderate durability but tend to degrade faster under prolonged exposure to moisture and UV light, resulting in reduced lifespan. The enhanced durability of cellophane coatings ensures better protection for packaging applications subjected to mechanical stress and environmental factors.

Applications in Packaging Industries

Cellophane coating offers excellent moisture barrier properties and clarity, making it ideal for packaging fresh produce, confectionery, and pharmaceuticals where product visibility and freshness are crucial. Nitrocellulose coating provides superior gloss and adhesion, commonly used in packaging for luxury goods, cosmetics, and tobacco products to enhance aesthetic appeal and durability. Both coatings serve critical roles in packaging industries by balancing protective qualities with consumer-oriented presentation needs.

Choosing the Right Coating for Your Product

Cellophane coating offers superior moisture and oxygen barrier properties, making it ideal for food packaging that requires extended shelf life and freshness preservation. Nitrocellulose coating provides excellent adhesion and glossy finishes, often preferred for decorative purposes and products needing quick drying times. Selecting the right coating depends on product requirements such as durability, appearance, and protection against environmental factors.

Cellophane Coating vs Nitrocellulose Coating Infographic

materialdif.com

materialdif.com