Cellophane pet is derived from cellulose fiber, offering natural biodegradability and excellent breathability, making it ideal for sustainable packaging. In contrast, PLA film is a bio-based polymer produced from fermented plant starch, providing strong barrier properties and greater rigidity but with slower decomposition in composting environments. Choosing between cellulose fiber and PLA film depends on desired environmental impact and functional performance in packaging applications.

Table of Comparison

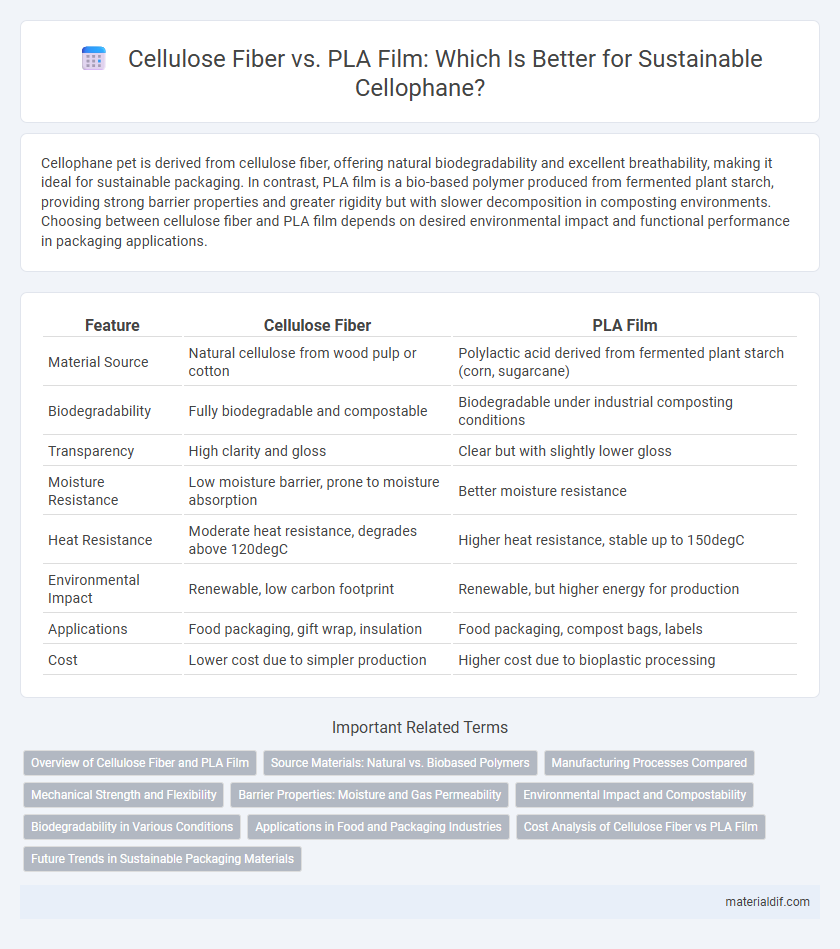

| Feature | Cellulose Fiber | PLA Film |

|---|---|---|

| Material Source | Natural cellulose from wood pulp or cotton | Polylactic acid derived from fermented plant starch (corn, sugarcane) |

| Biodegradability | Fully biodegradable and compostable | Biodegradable under industrial composting conditions |

| Transparency | High clarity and gloss | Clear but with slightly lower gloss |

| Moisture Resistance | Low moisture barrier, prone to moisture absorption | Better moisture resistance |

| Heat Resistance | Moderate heat resistance, degrades above 120degC | Higher heat resistance, stable up to 150degC |

| Environmental Impact | Renewable, low carbon footprint | Renewable, but higher energy for production |

| Applications | Food packaging, gift wrap, insulation | Food packaging, compost bags, labels |

| Cost | Lower cost due to simpler production | Higher cost due to bioplastic processing |

Overview of Cellulose Fiber and PLA Film

Cellulose fiber, derived from natural plant sources such as wood pulp and cotton, offers excellent biodegradability and renewable characteristics, making it an eco-friendly material for packaging and textile applications. PLA (polylactic acid) film, produced from fermented plant starch like corn or sugarcane, also provides compostability and a lower carbon footprint compared to petroleum-based plastics, but tends to have different mechanical and barrier properties. Both cellulose fiber and PLA film are key sustainable alternatives in the bioplastics industry, with cellulose fiber excelling in strength and breathability while PLA film is favored for clarity and moisture resistance.

Source Materials: Natural vs. Biobased Polymers

Cellulose fiber is derived from natural plant sources such as wood pulp, offering a renewable and biodegradable option for film production. PLA film, on the other hand, is made from biobased polymers synthesized from fermented plant starches like corn or sugarcane, combining sustainability with compostability. The fundamental difference lies in cellulose fiber's direct extraction from natural materials versus PLA's biochemical processing into bioplastics.

Manufacturing Processes Compared

Cellulose fiber production involves extracting cellulose from wood pulp or cotton linters, followed by purification, bleaching, and regeneration into thin, transparent sheets through processes like viscose or lyocell methods. PLA film manufacturing starts with fermenting renewable resources like corn starch or sugarcane into lactic acid, which is then polymerized into polylactic acid and extruded into films using melt extrusion techniques. While cellulose fiber relies on natural cellulose regeneration and chemical treatments, PLA film production is rooted in biopolymer synthesis and thermoplastic processing, affecting energy consumption and biodegradability profiles.

Mechanical Strength and Flexibility

Cellulose fiber films exhibit superior mechanical strength due to their natural polymeric structure, providing enhanced durability and resistance to tearing compared to PLA films. PLA films offer greater flexibility and elongation at break, making them suitable for applications requiring bending and folding without cracking. The difference in mechanical properties stems from cellulose's crystalline microfibril arrangement versus PLA's amorphous polymer chains, influencing their performance in packaging and biodegradable films.

Barrier Properties: Moisture and Gas Permeability

Cellulose fiber-based cellophane exhibits superior moisture barrier properties due to its dense, hydrophilic fiber structure that effectively limits water vapor transmission, whereas PLA film, derived from polylactic acid, shows higher moisture permeability. In terms of gas permeability, especially oxygen and carbon dioxide, cellophane provides excellent barrier performance attributed to its crystalline cellulose arrangement, while PLA films tend to have greater gas permeability, which can impact the shelf life of oxygen-sensitive products. These distinctions make cellophane ideal for applications requiring robust moisture and gas barriers, whereas PLA film is better suited for biodegradable packaging with moderate barrier demands.

Environmental Impact and Compostability

Cellulose fiber, derived from natural wood pulp, exhibits superior environmental benefits compared to PLA film due to its complete biodegradability and compostability within industrial and home compost settings. PLA film, made from polylactic acid sourced from fermented plant starch, offers compostability primarily in industrial facilities but struggles with home composting and may contribute to microplastic pollution if improperly disposed. Both materials reduce reliance on petroleum-based plastics, yet cellulose fiber presents a more sustainable lifecycle by breaking down efficiently without leaving harmful residues.

Biodegradability in Various Conditions

Cellulose fiber-based cellophane exhibits superior biodegradability across diverse environmental conditions, breaking down efficiently in soil, compost, and aquatic settings due to its natural polymer structure. PLA film, derived from synthetic lactic acid polymers, tends to require industrial composting facilities with higher temperatures to achieve complete degradation, limiting its biodegradability under ambient environmental conditions. The inherent composition of cellulose fibers allows for faster microbial assimilation compared to PLA, making cellophane a more environmentally sustainable packaging option in mixed disposal scenarios.

Applications in Food and Packaging Industries

Cellulose fiber, derived from natural sources like wood pulp, offers biodegradability and excellent oxygen permeability, making it ideal for food packaging that requires breathability to maintain freshness. PLA film, produced from renewable starches such as corn, provides strong mechanical properties and clarity, suitable for rigid packaging and transparent wraps. Both materials are increasingly adopted in the food and packaging industries for their eco-friendly profiles and ability to replace conventional plastics while meeting safety and preservation standards.

Cost Analysis of Cellulose Fiber vs PLA Film

Cellulose fiber film generally presents a lower production cost compared to PLA film due to its simpler extraction and processing methods derived from abundant natural sources like wood pulp. PLA film, made from polylactic acid via fermentation of plant starches such as corn, involves higher manufacturing expenses linked to feedstock purification and polymerization steps. Cost efficiency of cellulose fiber enhances its appeal for large-scale packaging applications where sustainability and budget constraints are critical factors.

Future Trends in Sustainable Packaging Materials

Cellulose fiber and PLA film represent key innovations in sustainable packaging materials, with cellulose fiber offering enhanced biodegradability and stronger barrier properties derived from renewable wood pulp. PLA film, made from polylactic acid sourced from corn starch, is gaining traction due to its compostability and compatibility with existing recycling systems. Future trends indicate a growing emphasis on hybrid materials combining cellulose fiber and PLA to achieve superior sustainability performance and scalability in eco-friendly packaging solutions.

Cellulose Fiber vs PLA Film Infographic

materialdif.com

materialdif.com