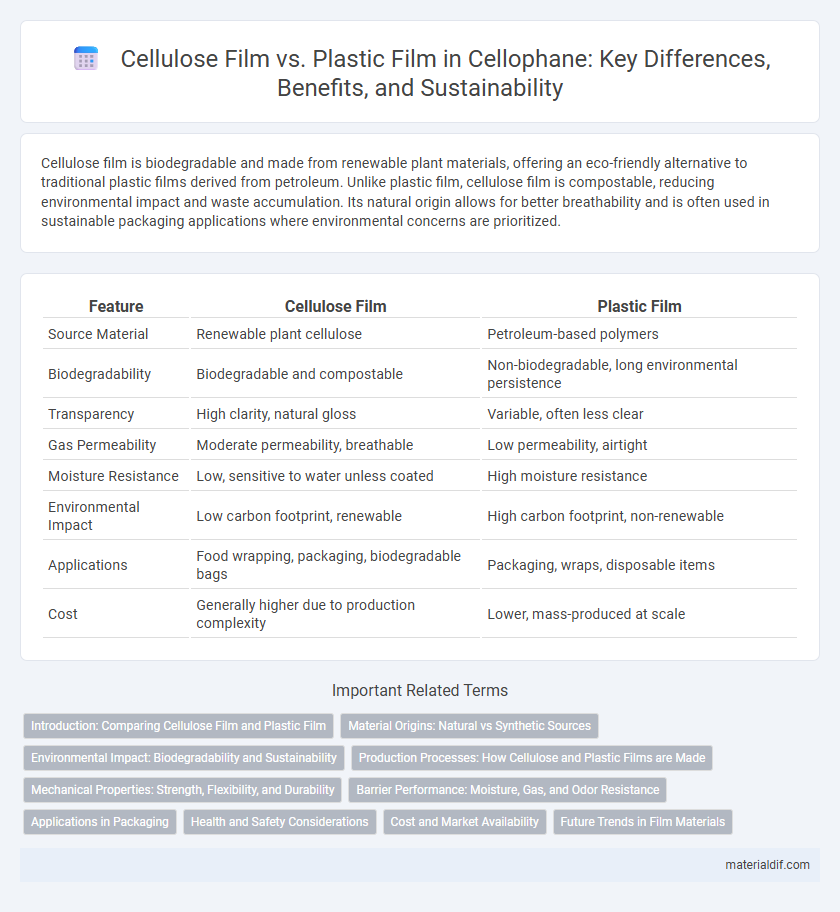

Cellulose film is biodegradable and made from renewable plant materials, offering an eco-friendly alternative to traditional plastic films derived from petroleum. Unlike plastic film, cellulose film is compostable, reducing environmental impact and waste accumulation. Its natural origin allows for better breathability and is often used in sustainable packaging applications where environmental concerns are prioritized.

Table of Comparison

| Feature | Cellulose Film | Plastic Film |

|---|---|---|

| Source Material | Renewable plant cellulose | Petroleum-based polymers |

| Biodegradability | Biodegradable and compostable | Non-biodegradable, long environmental persistence |

| Transparency | High clarity, natural gloss | Variable, often less clear |

| Gas Permeability | Moderate permeability, breathable | Low permeability, airtight |

| Moisture Resistance | Low, sensitive to water unless coated | High moisture resistance |

| Environmental Impact | Low carbon footprint, renewable | High carbon footprint, non-renewable |

| Applications | Food wrapping, packaging, biodegradable bags | Packaging, wraps, disposable items |

| Cost | Generally higher due to production complexity | Lower, mass-produced at scale |

Introduction: Comparing Cellulose Film and Plastic Film

Cellulose film is derived from natural fibers, offering biodegradability and compostability, whereas plastic film is typically produced from petrochemicals with limited environmental degradation. Cellulose films provide superior breathability and reduced moisture retention, making them ideal for food packaging that requires freshness preservation. Plastic films excel in durability and cost-effectiveness but contribute significantly to long-term pollution due to their persistent nature in ecosystems.

Material Origins: Natural vs Synthetic Sources

Cellulose film is derived from natural sources such as wood pulp and cotton fibers, making it biodegradable and environmentally friendly. Plastic film, on the other hand, is synthesized from petrochemicals, relying on non-renewable fossil fuels and contributing to long-term pollution. The renewable origin of cellulose film contrasts sharply with the synthetic composition of conventional plastic films.

Environmental Impact: Biodegradability and Sustainability

Cellulose film, derived from renewable plant-based cellulose, offers superior biodegradability compared to conventional plastic films made from petroleum-based polymers. Unlike plastic films that persist in the environment for centuries, cellulose films decompose naturally within weeks, significantly reducing landfill waste and microplastic pollution. The sustainability of cellulose film is enhanced through its production from renewable resources and lower carbon footprint, making it an eco-friendly alternative in packaging applications.

Production Processes: How Cellulose and Plastic Films are Made

Cellulose film is produced through a natural process that involves extracting cellulose from wood pulp or cotton fibers, followed by chemical treatment, and then formed into thin transparent sheets using a regeneration method. Plastic films, such as polyethylene or polypropylene, are manufactured through polymerization of petroleum-based monomers, melted, and extruded into thin films using processes like blown film extrusion or cast film extrusion. The cellulose film production relies on renewable raw materials and complex regeneration, while plastic film production depends on synthetic polymers and energy-intensive extrusion techniques.

Mechanical Properties: Strength, Flexibility, and Durability

Cellulose film exhibits superior biodegradability and moderate tensile strength compared to traditional plastic film, which often boasts higher mechanical strength but lower environmental compatibility. Cellulose-based films offer excellent flexibility and resistance to tearing due to their natural polymer structure, while many plastic films, such as polyethylene, deliver greater durability under harsh conditions but can degrade into microplastics. The strength-to-weight ratio of cellulose film supports sustainable packaging applications by balancing mechanical performance with eco-friendly properties, making it a viable alternative to conventional plastic films.

Barrier Performance: Moisture, Gas, and Odor Resistance

Cellulose film exhibits superior moisture barrier properties due to its hydrophilic nature, effectively limiting water vapor transmission compared to many conventional plastic films. Its inherent gas barrier performance, particularly against oxygen and carbon dioxide, ensures prolonged freshness and reduces spoilage in packaged goods. While cellulose film offers excellent odor resistance by preventing the permeation of volatile compounds, certain plastic films with specialized coatings can mimic these properties but often lack the biodegradability advantage.

Applications in Packaging

Cellulose film, derived from natural cellulose fibers, is biodegradable and widely used in eco-friendly packaging for food products such as bakery goods, confectionery, and fresh produce due to its breathability and moisture resistance. Plastic films like polyethylene and polypropylene dominate packaging applications with superior durability, moisture barrier properties, and flexibility, ideal for long shelf-life items such as snacks, frozen foods, and pharmaceuticals. Packaging industries increasingly favor cellulose film for sustainable branding while plastic films remain essential for high-performance and cost-effective packaging solutions.

Health and Safety Considerations

Cellulose film, derived from natural cellulose fibers, offers superior breathability and biodegradability compared to conventional plastic films, reducing the risk of harmful chemical leaching and environmental pollution. Unlike plastic films that may contain additives such as phthalates and bisphenol A (BPA), cellulose films are free from synthetic toxins, making them a safer choice for food packaging and direct contact applications. The non-toxic and compostable nature of cellulose film enhances workplace safety and consumer health, minimizing long-term exposure to potentially hazardous substances commonly associated with plastic films.

Cost and Market Availability

Cellulose film generally costs more than plastic film due to its renewable raw materials and sustainable production processes. Plastic film dominates the market with higher availability and a broader range of applications, benefiting from large-scale manufacturing and lower price points. Consumers seeking eco-friendly packaging increasingly choose cellulose film despite the cost premium and limited supply.

Future Trends in Film Materials

Cellulose film, derived from renewable resources, is gaining traction due to its biodegradability and reduced environmental impact compared to conventional plastic films made from petrochemicals. Innovations in bio-based coatings and enhanced barrier properties are expanding cellulose film applications in food packaging and sustainable products. Future trends indicate a significant shift toward hybrid films combining cellulose with biodegradable polymers to improve performance while addressing plastic pollution concerns.

Cellulose film vs Plastic film Infographic

materialdif.com

materialdif.com