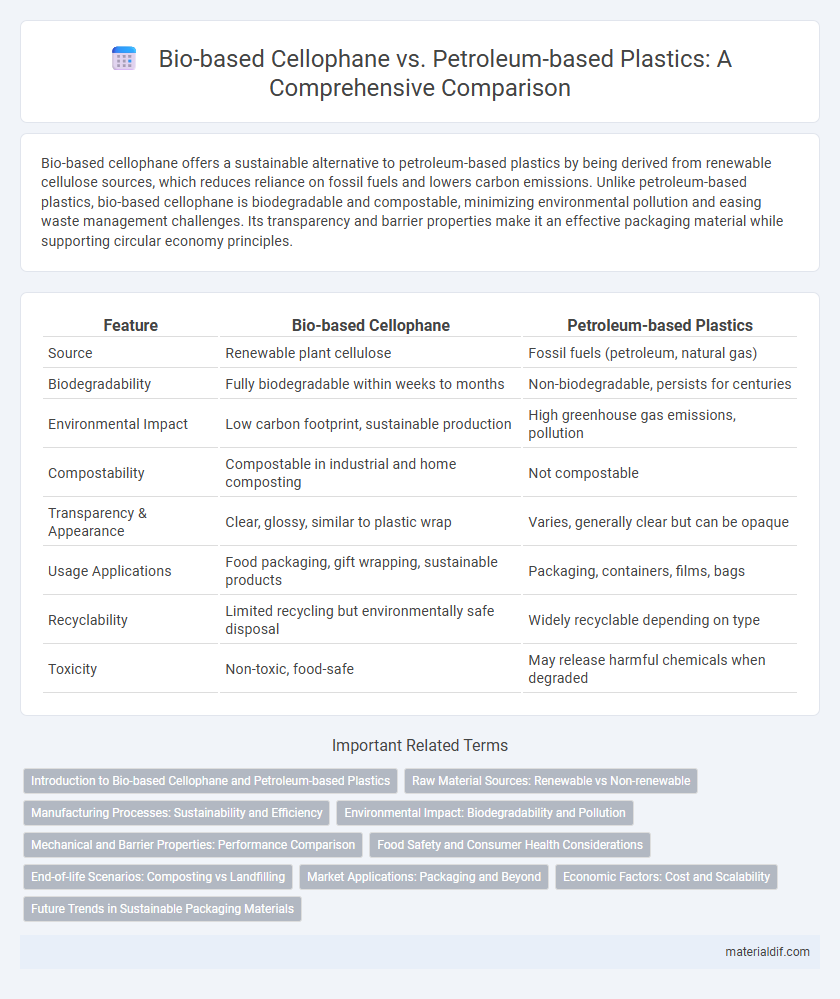

Bio-based cellophane offers a sustainable alternative to petroleum-based plastics by being derived from renewable cellulose sources, which reduces reliance on fossil fuels and lowers carbon emissions. Unlike petroleum-based plastics, bio-based cellophane is biodegradable and compostable, minimizing environmental pollution and easing waste management challenges. Its transparency and barrier properties make it an effective packaging material while supporting circular economy principles.

Table of Comparison

| Feature | Bio-based Cellophane | Petroleum-based Plastics |

|---|---|---|

| Source | Renewable plant cellulose | Fossil fuels (petroleum, natural gas) |

| Biodegradability | Fully biodegradable within weeks to months | Non-biodegradable, persists for centuries |

| Environmental Impact | Low carbon footprint, sustainable production | High greenhouse gas emissions, pollution |

| Compostability | Compostable in industrial and home composting | Not compostable |

| Transparency & Appearance | Clear, glossy, similar to plastic wrap | Varies, generally clear but can be opaque |

| Usage Applications | Food packaging, gift wrapping, sustainable products | Packaging, containers, films, bags |

| Recyclability | Limited recycling but environmentally safe disposal | Widely recyclable depending on type |

| Toxicity | Non-toxic, food-safe | May release harmful chemicals when degraded |

Introduction to Bio-based Cellophane and Petroleum-based Plastics

Bio-based cellophane is a renewable, biodegradable film derived from cellulose extracted from wood pulp or cotton fibers, offering an eco-friendly alternative to petroleum-based plastics. Petroleum-based plastics, primarily composed of synthetic polymers like polyethylene and polypropylene, rely on fossil fuels, contributing significantly to environmental pollution and non-biodegradability. The shift towards bio-based cellophane addresses sustainability challenges by reducing carbon footprint and enhancing compostability compared to traditional petroleum-based plastic films.

Raw Material Sources: Renewable vs Non-renewable

Bio-based cellophane is derived from renewable raw materials such as cellulose extracted from sustainably managed wood or cotton fibers, ensuring a lower environmental footprint. In contrast, petroleum-based plastics rely on non-renewable fossil fuels like crude oil and natural gas, contributing to resource depletion and higher greenhouse gas emissions. The renewable origin of bio-based cellophane supports circular economy principles by enabling biodegradability and reducing reliance on finite resources.

Manufacturing Processes: Sustainability and Efficiency

Bio-based cellophane is produced from cellulose derived primarily from wood pulp through an eco-friendly regeneration process that minimizes chemical waste and energy consumption, contrasting with petroleum-based plastics synthesized from fossil fuels involving complex, energy-intensive polymerization. The manufacturing of bio-based cellophane integrates renewable resources, leading to lower carbon emissions and enhanced biodegradability, whereas petroleum-based plastics contribute significantly to environmental pollution and resource depletion. Advances in cellulose solvent technologies enable more efficient production of bio-based cellophane, fostering sustainability in packaging industries compared to conventional plastic manufacturing.

Environmental Impact: Biodegradability and Pollution

Bio-based cellophane offers significant environmental advantages over petroleum-based plastics due to its complete biodegradability and lower pollution levels. Unlike conventional plastics that persist for centuries in landfills and oceans, cellophane decomposes naturally within weeks, reducing microplastic contamination. The production of bio-based cellophane also generates fewer greenhouse gas emissions, contributing to a smaller carbon footprint throughout its lifecycle.

Mechanical and Barrier Properties: Performance Comparison

Bio-based cellophane offers superior oxygen and aroma barrier properties compared to most petroleum-based plastics, enhancing food preservation and extending shelf life. While petroleum-based plastics like polyethylene exhibit higher tensile strength and flexibility, bio-based cellophane's excellent grease resistance and moisture barrier capabilities make it an eco-friendly alternative in packaging applications. The biodegradability of bio-based cellophane further distinguishes it, reducing environmental impact without compromising essential mechanical and barrier performance.

Food Safety and Consumer Health Considerations

Bio-based cellophane offers a safer alternative to petroleum-based plastics by being free from harmful chemicals like phthalates and BPA, which are commonly found in conventional plastic packaging and linked to health risks. Its natural cellulose composition reduces the risk of chemical migration into food products, ensuring higher food safety standards. Consumers benefit from bio-based cellophane's biodegradability and non-toxic properties, aligning with increasing demands for sustainable and health-conscious packaging solutions.

End-of-life Scenarios: Composting vs Landfilling

Bio-based cellophane, derived from cellulose, is biodegradable and suited for industrial composting, breaking down into water, carbon dioxide, and biomass within weeks under optimal conditions. Petroleum-based plastics, composed of long polymer chains, persist in landfills for centuries, releasing harmful microplastics and greenhouse gases during degradation. Composting bio-based cellophane reduces landfill volume and soil contamination, offering a sustainable end-of-life scenario compared to the environmental hazards posed by landfilling conventional plastics.

Market Applications: Packaging and Beyond

Bio-based cellophane, derived from renewable cellulose sources, offers superior biodegradability and compostability compared to petroleum-based plastics, making it ideal for sustainable packaging solutions such as food wraps and biodegradable bags. Its market applications extend beyond packaging into areas like agricultural films and medical wraps, where eco-friendly and breathable materials are essential. Growing consumer demand for green products drives increased adoption of bio-based cellophane, positioning it as a viable alternative in markets traditionally dominated by petroleum-based plastics.

Economic Factors: Cost and Scalability

Bio-based cellophane offers a competitive edge in cost-effectiveness due to renewable raw materials, reducing dependency on volatile petroleum prices. Its scalability benefits from sustainable cellulose sources like wood pulp, enabling consistent large-scale production compared to fossil fuel-based plastics reliant on fluctuating oil markets. Economic advantages include potential government incentives for eco-friendly materials, offsetting initial investment costs and promoting broader market adoption.

Future Trends in Sustainable Packaging Materials

Bio-based cellophane, derived from renewable cellulose sources, offers a biodegradable alternative to petroleum-based plastics, reducing environmental impact and supporting circular economy goals. Future trends in sustainable packaging focus on enhancing the barrier properties and durability of bio-based cellophane to meet industry standards while minimizing plastic waste. Innovations in bio-based coatings and blending with other renewable materials are expected to drive the adoption of eco-friendly packaging solutions globally.

Bio-based Cellophane vs Petroleum-based Plastics Infographic

materialdif.com

materialdif.com