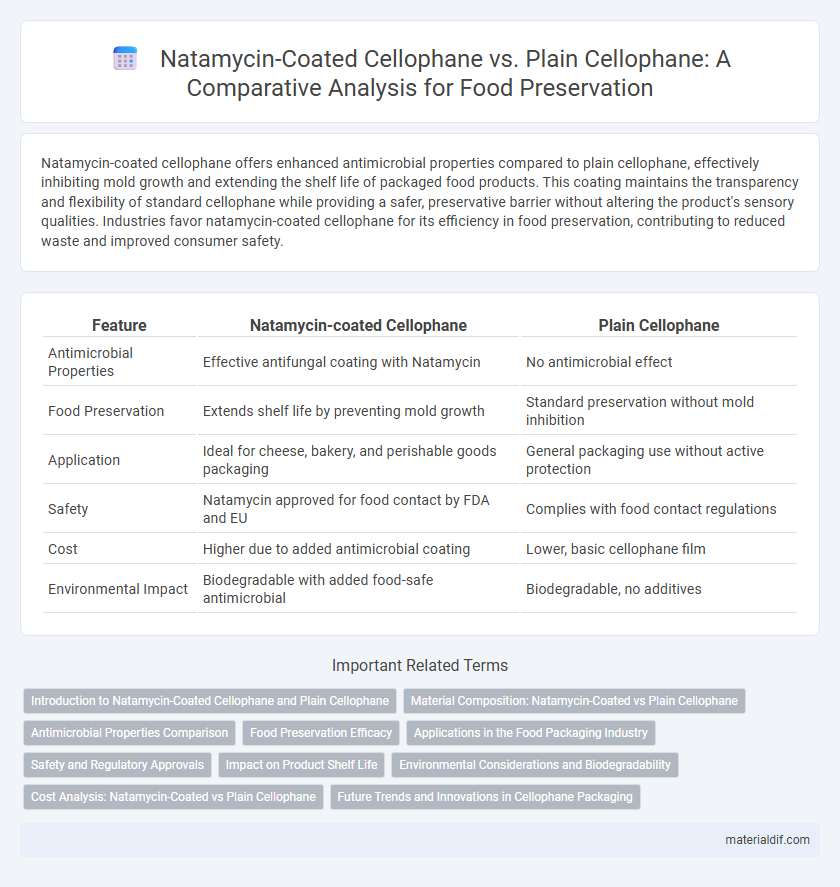

Natamycin-coated cellophane offers enhanced antimicrobial properties compared to plain cellophane, effectively inhibiting mold growth and extending the shelf life of packaged food products. This coating maintains the transparency and flexibility of standard cellophane while providing a safer, preservative barrier without altering the product's sensory qualities. Industries favor natamycin-coated cellophane for its efficiency in food preservation, contributing to reduced waste and improved consumer safety.

Table of Comparison

| Feature | Natamycin-coated Cellophane | Plain Cellophane |

|---|---|---|

| Antimicrobial Properties | Effective antifungal coating with Natamycin | No antimicrobial effect |

| Food Preservation | Extends shelf life by preventing mold growth | Standard preservation without mold inhibition |

| Application | Ideal for cheese, bakery, and perishable goods packaging | General packaging use without active protection |

| Safety | Natamycin approved for food contact by FDA and EU | Complies with food contact regulations |

| Cost | Higher due to added antimicrobial coating | Lower, basic cellophane film |

| Environmental Impact | Biodegradable with added food-safe antimicrobial | Biodegradable, no additives |

Introduction to Natamycin-Coated Cellophane and Plain Cellophane

Natamycin-coated cellophane integrates a natural antifungal agent, natamycin, which enhances its ability to inhibit mold growth on food products, extending shelf life compared to plain cellophane. Plain cellophane serves as a transparent, biodegradable packaging film primarily used for moisture and oxygen barrier properties but lacks antimicrobial protection. The innovative coating of natamycin on cellophane addresses microbial spoilage while maintaining the film's inherent environmental benefits.

Material Composition: Natamycin-Coated vs Plain Cellophane

Natamycin-coated cellophane integrates a bioactive antifungal agent within its polymer matrix, enhancing its protective properties against mold and yeast compared to plain cellophane. The coating process involves a thin, uniform application of natamycin, which maintains the intrinsic clarity and flexibility of the base cellulose film while adding antimicrobial functionality. In contrast, plain cellophane consists solely of regenerated cellulose without any antimicrobial additives, limiting its effectiveness in extending shelf life or preventing microbial contamination.

Antimicrobial Properties Comparison

Natamycin-coated cellophane exhibits significantly enhanced antimicrobial properties compared to plain cellophane, effectively inhibiting the growth of mold and yeast on food surfaces. The incorporation of natamycin, a natural antifungal agent, provides targeted protection that extends the shelf life of perishable goods without altering the packaging's physical characteristics. Studies demonstrate that natamycin-coated cellophane reduces microbial contamination by over 90%, making it a superior choice for food preservation applications.

Food Preservation Efficacy

Natamycin-coated cellophane significantly enhances food preservation by inhibiting mold and fungal growth, extending shelf life compared to plain cellophane. Studies demonstrate Natamycin's effectiveness as a natural antifungal agent that maintains food quality without altering taste or odor. This antimicrobial barrier reduces spoilage in dairy, baked goods, and processed meats, ensuring safer storage and longer freshness.

Applications in the Food Packaging Industry

Natamycin-coated cellophane offers enhanced antimicrobial properties that significantly extend the shelf life of perishable food products by inhibiting mold and yeast growth, making it ideal for dairy, meat, and bakery packaging. Compared to plain cellophane, this active packaging material reduces spoilage and food waste, supporting both food safety and sustainability goals. The integration of natamycin-coated cellophane in food packaging improves product quality and consumer trust by maintaining freshness without the use of synthetic preservatives.

Safety and Regulatory Approvals

Natamycin-coated cellophane is widely recognized for its antifungal properties and has received regulatory approvals from agencies like the FDA and EFSA for safe use in food packaging, ensuring consumer protection against mold contamination. In contrast, plain cellophane lacks active antimicrobial agents, offering basic mechanical protection without enhanced safety against fungal growth. Safety assessments confirm that natamycin coatings do not migrate in harmful amounts, making natamycin-coated cellophane a reliable option for extending product shelf life while complying with stringent regulatory standards.

Impact on Product Shelf Life

Natamycin-coated cellophane significantly extends product shelf life by inhibiting mold and yeast growth, compared to plain cellophane which offers no antimicrobial protection. Studies show that packaging with natamycin coating effectively preserves freshness and prevents spoilage in dairy and baked goods, resulting in prolonged marketability. This enhanced microbial barrier reduces waste and supports food safety, making natamycin-coated cellophane a superior choice for perishable items.

Environmental Considerations and Biodegradability

Natamycin-coated cellophane offers enhanced antimicrobial properties while maintaining similar biodegradability profiles to plain cellophane, ensuring effective preservation without compromising environmental sustainability. Unlike synthetic polymers, both natamycin-coated and plain cellophane are primarily derived from cellulose, enabling natural degradation in soil and water ecosystems. This biodegradable nature reduces microplastic pollution and supports circular economy goals in food packaging industries.

Cost Analysis: Natamycin-Coated vs Plain Cellophane

Natamycin-coated cellophane incurs higher production costs due to the additional antimicrobial coating process and the expense of natamycin as an active ingredient. Despite the elevated price, its enhanced shelf-life and reduced spoilage risk can lower overall food waste expenses, potentially offsetting initial investment in packaging. Conversely, plain cellophane offers a cost-effective packaging solution but lacks antimicrobial properties, potentially leading to increased product loss in perishable goods.

Future Trends and Innovations in Cellophane Packaging

Natamycin-coated cellophane is gaining traction as an innovative antimicrobial packaging solution that extends the shelf life of perishable foods by inhibiting mold and yeast growth. Future trends in cellophane packaging emphasize enhanced barrier properties, biodegradability, and integration of active substances like natural preservatives and nanomaterials to improve food safety and sustainability. Industry efforts focus on combining eco-friendly materials with advanced functional coatings to meet regulatory demands and consumer preferences for safer, longer-lasting packaged goods.

Natamycin-coated Cellophane vs Plain Cellophane Infographic

materialdif.com

materialdif.com