Cellophane windows offer superior biodegradability and a natural feel, making them an eco-friendly choice for sustainable packaging. In contrast, acetate windows provide greater clarity and moisture resistance, enhancing product visibility and durability. Choosing between cellophane and acetate windows depends on balancing environmental impact with functional performance in packaging design.

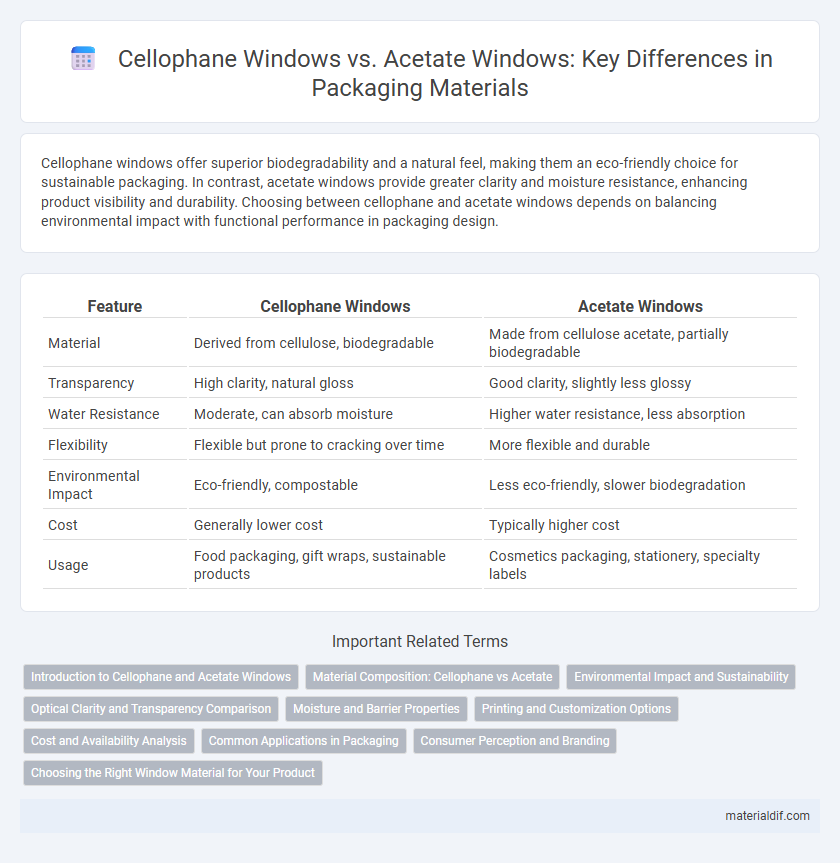

Table of Comparison

| Feature | Cellophane Windows | Acetate Windows |

|---|---|---|

| Material | Derived from cellulose, biodegradable | Made from cellulose acetate, partially biodegradable |

| Transparency | High clarity, natural gloss | Good clarity, slightly less glossy |

| Water Resistance | Moderate, can absorb moisture | Higher water resistance, less absorption |

| Flexibility | Flexible but prone to cracking over time | More flexible and durable |

| Environmental Impact | Eco-friendly, compostable | Less eco-friendly, slower biodegradation |

| Cost | Generally lower cost | Typically higher cost |

| Usage | Food packaging, gift wraps, sustainable products | Cosmetics packaging, stationery, specialty labels |

Introduction to Cellophane and Acetate Windows

Cellophane windows are biodegradable, made from regenerated cellulose, offering a transparent and moisture-resistant packaging option that appeals to eco-friendly markets. Acetate windows, derived from cellulose acetate, provide enhanced durability and clarity while maintaining biodegradability, commonly used in food packaging for a premium appearance. Both materials serve as sustainable alternatives to traditional plastic windows in packaging, with cellophane prioritizing biodegradability and acetate emphasizing strength and transparency.

Material Composition: Cellophane vs Acetate

Cellophane windows are made from regenerated cellulose, a natural polymer derived from wood pulp or cotton fibers, offering biodegradability and enhanced moisture resistance. Acetate windows, composed of cellulose acetate, a synthetic derivative of cellulose treated with acetic acid, provide greater clarity and durability but are less biodegradable than cellophane. The choice between cellophane and acetate windows depends on factors such as environmental impact and required transparency for packaging applications.

Environmental Impact and Sustainability

Cellophane windows, derived from cellulose, are biodegradable and compostable, offering a lower environmental footprint compared to acetate windows, which are made from cellulose acetate, a semi-synthetic polymer that degrades slower and can release harmful chemicals during breakdown. The production of cellophane involves fewer synthetic chemicals and relies on renewable resources, enhancing sustainability, whereas acetate manufacturing depends on fossil fuels and produces more persistent plastic waste. Choosing cellophane windows can significantly reduce plastic pollution and support circular economy goals in packaging industries.

Optical Clarity and Transparency Comparison

Cellophane windows offer superior optical clarity due to their smooth, non-crystalline structure, enabling higher light transmission and reduced haze compared to acetate windows. Acetate windows, while more flexible, tend to exhibit slight opacity and lower transparency, which can affect visibility and overall appearance. The enhanced transparency of cellophane makes it a preferred choice for packaging requiring clear product visibility and aesthetic appeal.

Moisture and Barrier Properties

Cellophane windows exhibit superior moisture resistance due to their dense cellulose structure, effectively blocking water vapor and preserving product freshness. In contrast, acetate windows offer moderate moisture barrier properties but provide enhanced clarity and flexibility. The choice between cellophane and acetate windows depends on the required balance between moisture protection and visual appeal in packaging applications.

Printing and Customization Options

Cellophane windows offer limited printing options due to their natural cellulose base, which restricts the types of inks and printing techniques compatible with the material. Acetate windows provide superior customization opportunities, as they support a wider range of printing methods, including UV and digital printing, allowing for vibrant colors and detailed graphics. Manufacturers favor acetate for brands seeking high-quality, customizable packaging solutions with sharp, durable prints.

Cost and Availability Analysis

Cellophane windows typically offer a lower-cost option compared to acetate windows, making them more accessible for budget-conscious packaging solutions. Availability of cellophane is widespread due to its long-standing presence in packaging, whereas acetate windows may face supply limitations depending on manufacturing location and demand. Cost efficiency and broader market availability position cellophane as the preferred choice for many businesses seeking transparent window materials.

Common Applications in Packaging

Cellophane windows are commonly used in packaging for food products like baked goods, candies, and fresh produce to provide a clear, moisture-resistant barrier that showcases product freshness. Acetate windows, favored in packaging for cosmetics, gift boxes, and apparel, offer superior clarity and durability while maintaining flexibility for intricate designs. Both materials enhance product visibility and consumer appeal, with cellophane excelling in biodegradability and acetate valued for its higher tear resistance.

Consumer Perception and Branding

Cellophane windows convey a natural, eco-friendly image due to their biodegradable properties, appealing to environmentally conscious consumers. Acetate windows, while more durable and clear, often lack the organic appeal, which can impact brand perception in markets prioritizing sustainability. Brands leveraging cellophane emphasize transparency with a green narrative, strengthening consumer trust and differentiating their packaging.

Choosing the Right Window Material for Your Product

Cellophane windows offer superior biodegradability and a natural, glossy finish that enhances product visibility while maintaining environmental sustainability. Acetate windows provide excellent clarity and durability, making them ideal for products requiring moisture resistance and longer shelf life. Evaluating factors like environmental impact, clarity, and product protection ensures selecting the optimal window material tailored to packaging needs.

Cellophane Windows vs Acetate Windows Infographic

materialdif.com

materialdif.com