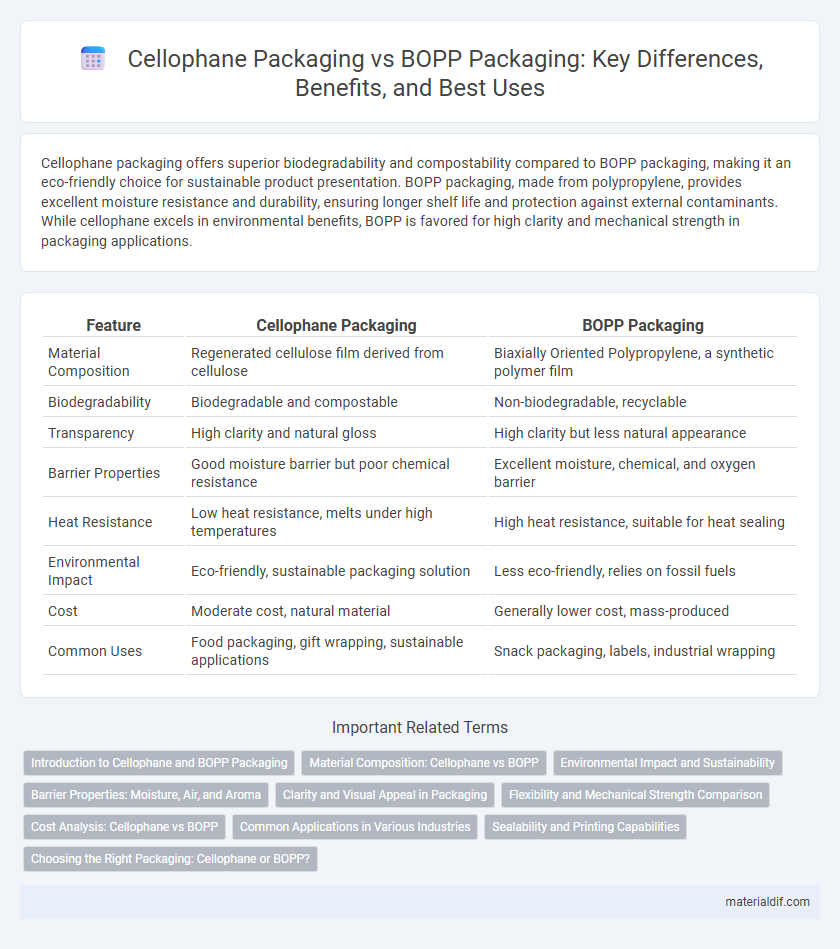

Cellophane packaging offers superior biodegradability and compostability compared to BOPP packaging, making it an eco-friendly choice for sustainable product presentation. BOPP packaging, made from polypropylene, provides excellent moisture resistance and durability, ensuring longer shelf life and protection against external contaminants. While cellophane excels in environmental benefits, BOPP is favored for high clarity and mechanical strength in packaging applications.

Table of Comparison

| Feature | Cellophane Packaging | BOPP Packaging |

|---|---|---|

| Material Composition | Regenerated cellulose film derived from cellulose | Biaxially Oriented Polypropylene, a synthetic polymer film |

| Biodegradability | Biodegradable and compostable | Non-biodegradable, recyclable |

| Transparency | High clarity and natural gloss | High clarity but less natural appearance |

| Barrier Properties | Good moisture barrier but poor chemical resistance | Excellent moisture, chemical, and oxygen barrier |

| Heat Resistance | Low heat resistance, melts under high temperatures | High heat resistance, suitable for heat sealing |

| Environmental Impact | Eco-friendly, sustainable packaging solution | Less eco-friendly, relies on fossil fuels |

| Cost | Moderate cost, natural material | Generally lower cost, mass-produced |

| Common Uses | Food packaging, gift wrapping, sustainable applications | Snack packaging, labels, industrial wrapping |

Introduction to Cellophane and BOPP Packaging

Cellophane is a transparent, thin film made from cellulose, known for its excellent breathability and biodegradability, commonly used in packaging to keep food fresh. BOPP (Biaxially Oriented Polypropylene) packaging, made from polypropylene film stretched in two directions, offers high clarity, moisture resistance, and durability, making it ideal for a wide range of consumer products. Both materials serve distinct purposes in packaging, with cellophane favored for eco-friendly applications and BOPP preferred for its strength and barrier properties.

Material Composition: Cellophane vs BOPP

Cellophane packaging is made from regenerated cellulose derived from wood pulp, making it biodegradable and compostable, which appeals to eco-conscious consumers. BOPP (Biaxially Oriented Polypropylene) packaging is composed of polypropylene resin, a petroleum-based plastic that offers excellent moisture resistance, durability, and clarity but is less environmentally sustainable. The material composition of cellophane supports better biodegradability, whereas BOPP excels in barrier properties and mechanical strength for longer shelf life.

Environmental Impact and Sustainability

Cellophane packaging, derived from renewable cellulose, is biodegradable and compostable, offering a lower environmental footprint compared to BOPP packaging, which is petroleum-based and non-biodegradable. BOPP packaging is recyclable but often ends up in landfills or oceans, contributing to plastic pollution and long-term sustainability challenges. Choosing cellophane supports circular economy principles by reducing plastic waste and enhancing biodegradability in packaging applications.

Barrier Properties: Moisture, Air, and Aroma

Cellophane packaging offers excellent moisture barrier properties, making it highly effective in preserving food freshness, but its air barrier capabilities are moderate, which can affect long-term product shelf life. BOPP (Biaxially Oriented Polypropylene) packaging excels in providing superior air and aroma barrier properties, significantly reducing oxygen transmission rates and preventing aroma loss. Both materials differ in their barrier performance, with cellophane favored for high moisture resistance and BOPP preferred where air and aroma retention are critical.

Clarity and Visual Appeal in Packaging

Cellophane packaging offers superior clarity and a natural, glossy finish that enhances product visibility, making it ideal for showcasing items with vibrant colors. BOPP packaging provides high gloss and a smooth surface but often lacks the same level of transparency as cellophane, which can slightly diminish the visual appeal of certain products. Brands prioritizing premium aesthetics and crystal-clear display frequently opt for cellophane to maximize consumer attraction through packaging.

Flexibility and Mechanical Strength Comparison

Cellophane packaging offers superior flexibility due to its natural cellulose composition, allowing it to conform easily to irregular shapes without tearing. In contrast, BOPP (Biaxially Oriented Polypropylene) packaging provides enhanced mechanical strength with higher tensile strength and puncture resistance, making it more suitable for heavy-duty applications. While cellophane excels in flexibility and biodegradability, BOPP outperforms in durability and moisture barrier properties.

Cost Analysis: Cellophane vs BOPP

Cellophane packaging generally has lower material costs compared to BOPP packaging, making it a cost-effective choice for budget-sensitive applications. BOPP packaging offers better durability and moisture resistance, which can reduce product loss and offset its higher upfront expenses in long-term use. When conducting a cost analysis, companies should consider both initial material costs and potential savings from enhanced product protection and shelf life provided by BOPP.

Common Applications in Various Industries

Cellophane packaging is widely used in food industries for wrapping fresh produce, bakery items, and confectionery due to its excellent moisture and aroma barrier properties. BOPP (Biaxially Oriented Polypropylene) packaging dominates in consumer goods packaging, including snacks, textiles, and pharmaceuticals, thanks to its high tensile strength and clarity. Both materials find application in retail packaging, but BOPP's superior printability and resistance to oils and greases make it preferable for durability-focused uses.

Sealability and Printing Capabilities

Cellophane packaging offers strong sealability due to its inherent hygroscopic properties, creating airtight seals that preserve product freshness effectively. In contrast, BOPP (Biaxially Oriented Polypropylene) packaging provides superior printing capabilities with vibrant, high-resolution graphics enabled by its smooth surface and excellent ink adhesion. While cellophane seals better under high humidity conditions, BOPP excels in branding appeal and customization through advanced printing technology.

Choosing the Right Packaging: Cellophane or BOPP?

Cellophane packaging offers superior biodegradability and excellent moisture barrier properties, making it ideal for eco-conscious brands seeking sustainable solutions. BOPP (Biaxially Oriented Polypropylene) packaging provides high clarity, durability, and resistance to oil and grease, suitable for long shelf life and product protection. Choosing the right packaging depends on balancing environmental impact with functional needs such as product shelf stability and visual appeal.

Cellophane Packaging vs BOPP Packaging Infographic

materialdif.com

materialdif.com