Cellophane packaging offers excellent clarity and biodegradability, making it a sustainable choice for eco-conscious consumers, while PLA packaging is derived from renewable resources like corn starch and provides compostability under industrial conditions. Both options reduce reliance on traditional plastics, but cellophane tends to have better moisture resistance, whereas PLA packaging excels in versatility and heat sealing properties. Choosing between cellophane and PLA depends on specific product needs, environmental goals, and disposal infrastructure availability.

Table of Comparison

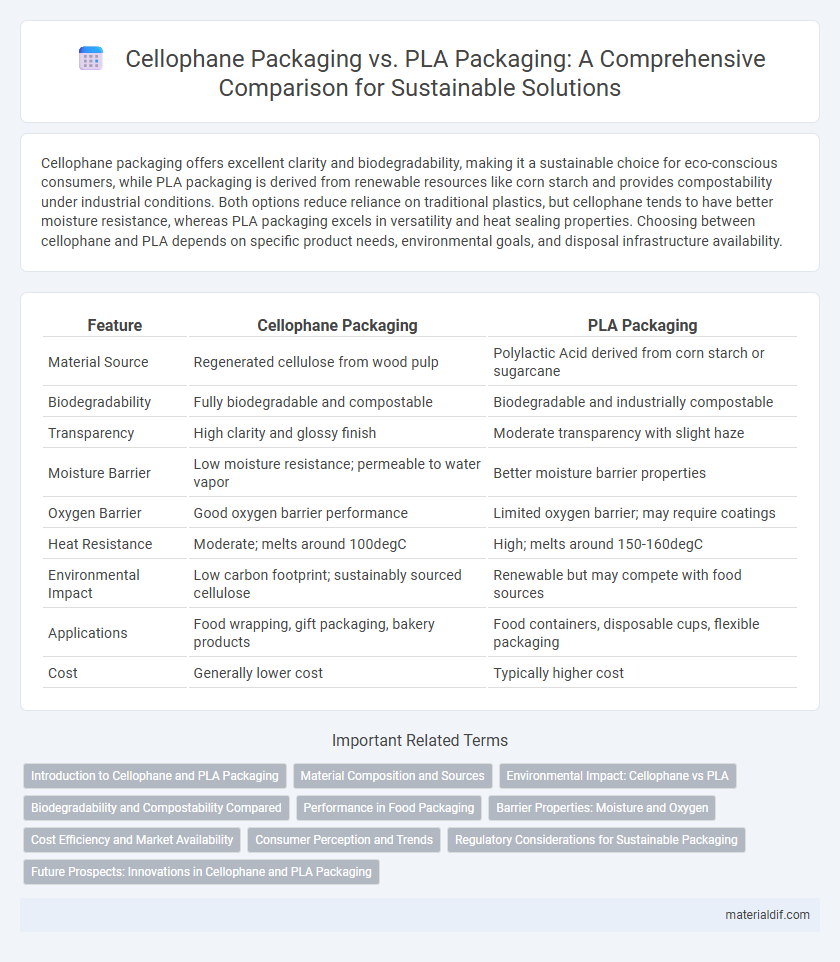

| Feature | Cellophane Packaging | PLA Packaging |

|---|---|---|

| Material Source | Regenerated cellulose from wood pulp | Polylactic Acid derived from corn starch or sugarcane |

| Biodegradability | Fully biodegradable and compostable | Biodegradable and industrially compostable |

| Transparency | High clarity and glossy finish | Moderate transparency with slight haze |

| Moisture Barrier | Low moisture resistance; permeable to water vapor | Better moisture barrier properties |

| Oxygen Barrier | Good oxygen barrier performance | Limited oxygen barrier; may require coatings |

| Heat Resistance | Moderate; melts around 100degC | High; melts around 150-160degC |

| Environmental Impact | Low carbon footprint; sustainably sourced cellulose | Renewable but may compete with food sources |

| Applications | Food wrapping, gift packaging, bakery products | Food containers, disposable cups, flexible packaging |

| Cost | Generally lower cost | Typically higher cost |

Introduction to Cellophane and PLA Packaging

Cellophane is a thin, transparent film made from regenerated cellulose, widely used for its excellent moisture barrier and biodegradable properties in packaging. PLA packaging, derived from polylactic acid sourced from renewable resources like corn starch, offers a compostable alternative with a similar transparent appearance. Both materials prioritize sustainability but differ in feedstock origin and industrial composting requirements.

Material Composition and Sources

Cellophane packaging is made from regenerated cellulose derived from natural sources like wood pulp and cotton fibers, offering biodegradability and compostability without relying on petrochemicals. PLA packaging consists of polylactic acid, a bioplastic produced through the fermentation of renewable plant sugars, primarily corn starch or sugarcane, resulting in a compostable material with properties suitable for packaging applications. Both materials provide sustainable alternatives to conventional plastics, but cellophane originates directly from cellulose fibers, whereas PLA is synthesized through a biotechnological fermentation process.

Environmental Impact: Cellophane vs PLA

Cellophane packaging is derived from cellulose, a natural polymer sourced from wood pulp, and is biodegradable under industrial composting conditions, reducing plastic pollution. PLA packaging, made from fermented plant starch such as corn, is also compostable but often requires specific facilities to break down efficiently, limiting its environmental benefits in typical waste streams. The environmental impact comparison shows cellophane's renewable origin and biodegradability as sustainable advantages, while PLA's resource-intensive production and composting limitations present challenges for widespread ecological benefits.

Biodegradability and Compostability Compared

Cellophane packaging, derived from cellulose, is biodegradable and compostable, breaking down naturally within a few weeks under industrial composting conditions. PLA (polylactic acid) packaging, made from renewable resources like corn starch, also offers compostability but requires specific industrial composting facilities to decompose effectively, often taking longer than cellophane. Both materials reduce environmental impact compared to conventional plastics, but cellophane's natural cellulose base allows for faster biodegradation and broader composting compatibility.

Performance in Food Packaging

Cellophane packaging offers excellent oxygen and moisture barrier properties, making it ideal for preserving freshness and extending shelf life in food packaging. PLA (polylactic acid) packaging, derived from renewable resources, provides good transparency and biodegradability but generally exhibits lower moisture resistance and heat tolerance compared to cellophane. The superior performance of cellophane in maintaining product quality under varying storage conditions positions it as a preferred choice for sensitive food items requiring extended freshness.

Barrier Properties: Moisture and Oxygen

Cellophane packaging offers excellent oxygen barrier properties but has moderate resistance to moisture, making it suitable for products sensitive to oxidation but less ideal in high-humidity environments. PLA (polylactic acid) packaging provides good moisture barrier properties, preventing water vapor transmission effectively, but its oxygen barrier performance is inferior compared to cellophane. Choosing between cellophane and PLA depends on the specific product's sensitivity to oxygen and moisture exposure, with cellophane favoring oxygen-sensitive goods and PLA better for moisture-sensitive applications.

Cost Efficiency and Market Availability

Cellophane packaging typically offers greater cost efficiency due to its lower raw material and production expenses compared to PLA packaging, which relies on more costly biodegradable biopolymers. Market availability favors cellophane with widespread manufacturing infrastructure and global distribution, whereas PLA packaging, though growing in demand for sustainability, remains less accessible in many regions. Businesses seeking economical and readily available options often prefer cellophane, while PLA suits niche markets emphasizing eco-friendly material compliance despite higher costs.

Consumer Perception and Trends

Cellophane packaging is favored for its natural, biodegradable properties, appealing to eco-conscious consumers seeking transparency and sustainability. PLA packaging, derived from renewable resources like corn starch, is praised for its compostability but sometimes perceived as less durable or clear compared to cellophane. Current trends show increasing consumer demand for packaging that balances environmental impact with product visibility, often positioning cellophane as a premium choice in sustainable packaging solutions.

Regulatory Considerations for Sustainable Packaging

Cellophane packaging, derived from cellulose, is widely recognized for its biodegradability and compostability, aligning with stringent environmental regulations such as the European Union's EN 13432 standard for industrial composting. PLA packaging, made from polylactic acid sourced from renewable resources like corn starch, also meets key regulatory standards including FDA approval for food contact and ASTM D6400 certification for compostability in the US. Regulatory considerations emphasize the need for clear labeling and certification to ensure compliance with waste management policies and facilitate consumer awareness of sustainable packaging options.

Future Prospects: Innovations in Cellophane and PLA Packaging

Cellophane packaging continues to evolve with innovations targeting improved biodegradability and moisture resistance, making it a sustainable option for food and cosmetic industries. PLA (polylactic acid) packaging advances focus on enhanced clarity and heat resistance, driven by bioplastic research and increasing demand for compostable alternatives. Future prospects highlight hybrid materials combining cellophane's natural cellulose base with PLA's bio-based polymers to create versatile, eco-friendly packaging solutions.

Cellophane Packaging vs PLA Packaging Infographic

materialdif.com

materialdif.com