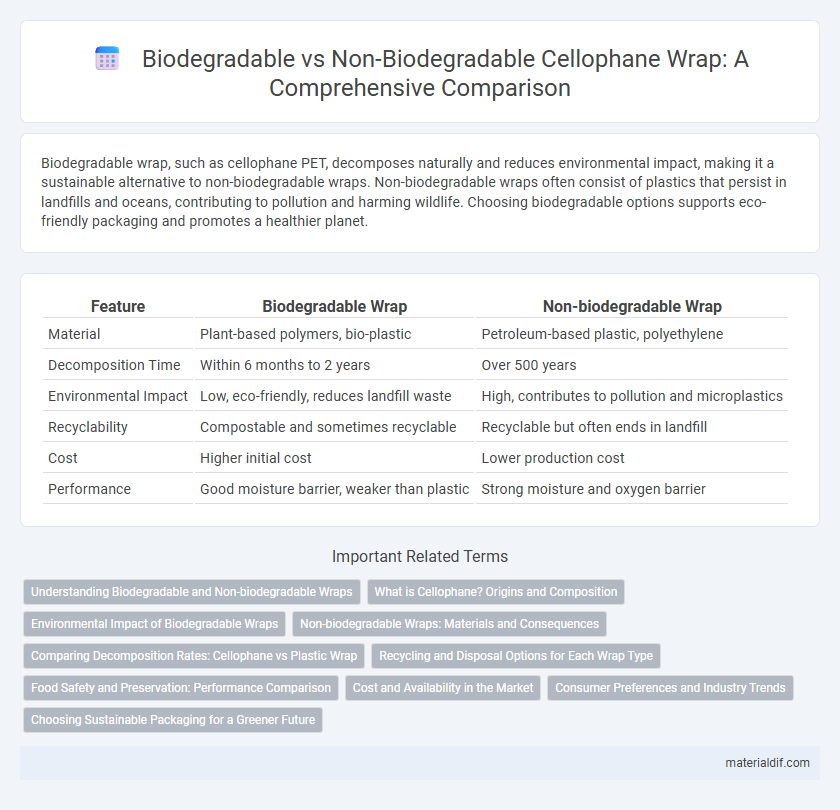

Biodegradable wrap, such as cellophane PET, decomposes naturally and reduces environmental impact, making it a sustainable alternative to non-biodegradable wraps. Non-biodegradable wraps often consist of plastics that persist in landfills and oceans, contributing to pollution and harming wildlife. Choosing biodegradable options supports eco-friendly packaging and promotes a healthier planet.

Table of Comparison

| Feature | Biodegradable Wrap | Non-biodegradable Wrap |

|---|---|---|

| Material | Plant-based polymers, bio-plastic | Petroleum-based plastic, polyethylene |

| Decomposition Time | Within 6 months to 2 years | Over 500 years |

| Environmental Impact | Low, eco-friendly, reduces landfill waste | High, contributes to pollution and microplastics |

| Recyclability | Compostable and sometimes recyclable | Recyclable but often ends in landfill |

| Cost | Higher initial cost | Lower production cost |

| Performance | Good moisture barrier, weaker than plastic | Strong moisture and oxygen barrier |

Understanding Biodegradable and Non-biodegradable Wraps

Biodegradable wraps, such as cellophane made from cellulose, break down naturally through microbial activity, reducing environmental impact and landfill accumulation. Non-biodegradable wraps, primarily composed of petroleum-based plastics like polyethylene, persist in ecosystems for hundreds of years, contributing to pollution and wildlife hazards. Understanding the material composition and decomposition rate of wraps is essential for selecting sustainable packaging solutions.

What is Cellophane? Origins and Composition

Cellophane is a biodegradable wrap made from regenerated cellulose derived from wood pulp or cotton fibers, offering an eco-friendly alternative to traditional non-biodegradable plastic wraps composed primarily of polyethylene or polyvinyl chloride. Developed in the early 20th century by Swiss chemist Jacques Brandenberger, cellophane's transparent and breathable properties make it ideal for food packaging while naturally decomposing without leaving harmful residues. Its cellulose base enables effective moisture control and gas permeability, supporting sustainable packaging solutions in contrast to petroleum-based wraps that contribute to long-term environmental pollution.

Environmental Impact of Biodegradable Wraps

Biodegradable cellophane wraps break down naturally within months, significantly reducing plastic pollution and landfill accumulation compared to non-biodegradable plastic wraps that persist for hundreds of years. Their production often uses renewable resources, lowering carbon footprints and decreasing reliance on fossil fuels. The environmental impact includes less soil and water contamination, promoting healthier ecosystems and more sustainable waste management practices.

Non-biodegradable Wraps: Materials and Consequences

Non-biodegradable wraps are primarily made from petroleum-based plastics such as polyethylene and polyvinyl chloride (PVC), which do not break down naturally in the environment. These materials persist for hundreds of years, contributing significantly to landfill waste and marine pollution. Their resistance to degradation leads to microplastic formation, posing severe risks to wildlife and ecosystems.

Comparing Decomposition Rates: Cellophane vs Plastic Wrap

Cellophane decomposes significantly faster than traditional plastic wrap, breaking down within 2 to 4 weeks under composting conditions, while plastic wrap can persist for hundreds of years in landfills. The biodegradable nature of cellophane, made from cellulose derived from wood pulp or cotton, allows microorganisms to efficiently digest it, reducing long-term environmental impact. In contrast, plastic wrap, composed of polyethylene or other synthetic polymers, resists biodegradation, contributing to persistent pollution and microplastic accumulation.

Recycling and Disposal Options for Each Wrap Type

Biodegradable cellophane wrap breaks down naturally within months under composting conditions, reducing landfill waste and offering eco-friendly disposal through industrial or home composting. Non-biodegradable plastic wraps resist decomposition, persist in landfills for centuries, and typically require recycling through specialized facilities that can process low-density polyethylene or polyvinyl chloride materials. Recycling options for biodegradable wraps remain limited due to contamination risks, while non-biodegradable wraps often face challenges in curbside recycling programs due to their thin, flexible nature, necessitating drop-off at dedicated plastic film recycling centers.

Food Safety and Preservation: Performance Comparison

Biodegradable cellophane wraps offer superior breathability, reducing moisture buildup and extending the freshness of perishable foods compared to non-biodegradable plastic wraps, which often trap condensation and accelerate spoilage. Natural cellulose-based cellophane is free from harmful chemicals like plasticizers and chlorine, enhancing food safety by minimizing the risk of chemical leaching. However, non-biodegradable wraps provide a tighter seal against oxygen and contaminants, offering longer preservation for dry foods but raising environmental and health concerns.

Cost and Availability in the Market

Biodegradable cellophane wraps typically have higher production costs due to the use of natural materials like cellulose, resulting in a slightly elevated price point compared to non-biodegradable plastic wraps. Availability of biodegradable wraps is increasing in specialty and eco-conscious markets but remains limited in mainstream retail channels, while non-biodegradable wraps dominate in cost-effective mass production and widespread distribution. Market trends indicate a gradual shift as consumer demand for sustainable products grows, yet price and accessibility continue to favor traditional plastic wraps.

Consumer Preferences and Industry Trends

Consumers increasingly prefer biodegradable wrap such as cellophane due to its environmental benefits and compostability, driving demand in sustainable packaging markets. Industry trends highlight a shift towards biodegradable materials, with companies investing in innovation to improve durability and reduce plastic waste. Market research reveals a growing segment of eco-conscious buyers prioritizing wraps that minimize ecological impact without compromising product quality.

Choosing Sustainable Packaging for a Greener Future

Biodegradable cellophane wrap, derived from renewable cellulose sources, breaks down naturally within months, significantly reducing landfill waste and environmental pollution compared to non-biodegradable plastic wraps made from petrochemicals. Choosing sustainable packaging like cellophane supports carbon footprint reduction, conserves fossil fuels, and promotes circular economy practices by enhancing compostability and recyclability. Embracing biodegradable wrap aligns with global sustainability goals and consumer demand for eco-friendly alternatives in food and retail industries.

Biodegradable Wrap vs Non-biodegradable Wrap Infographic

materialdif.com

materialdif.com