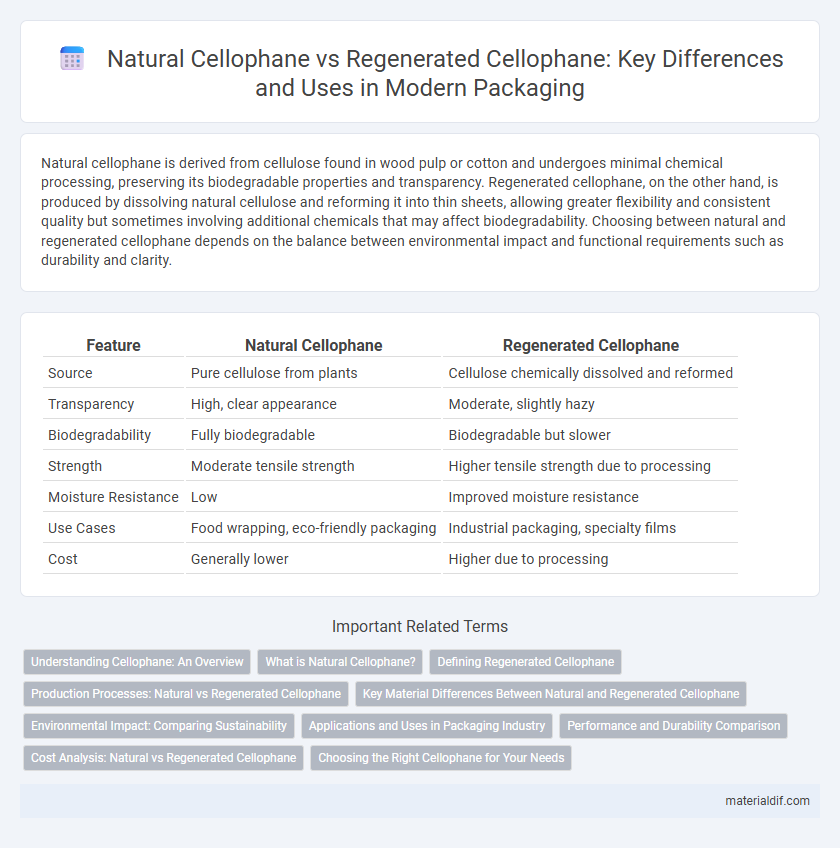

Natural cellophane is derived from cellulose found in wood pulp or cotton and undergoes minimal chemical processing, preserving its biodegradable properties and transparency. Regenerated cellophane, on the other hand, is produced by dissolving natural cellulose and reforming it into thin sheets, allowing greater flexibility and consistent quality but sometimes involving additional chemicals that may affect biodegradability. Choosing between natural and regenerated cellophane depends on the balance between environmental impact and functional requirements such as durability and clarity.

Table of Comparison

| Feature | Natural Cellophane | Regenerated Cellophane |

|---|---|---|

| Source | Pure cellulose from plants | Cellulose chemically dissolved and reformed |

| Transparency | High, clear appearance | Moderate, slightly hazy |

| Biodegradability | Fully biodegradable | Biodegradable but slower |

| Strength | Moderate tensile strength | Higher tensile strength due to processing |

| Moisture Resistance | Low | Improved moisture resistance |

| Use Cases | Food wrapping, eco-friendly packaging | Industrial packaging, specialty films |

| Cost | Generally lower | Higher due to processing |

Understanding Cellophane: An Overview

Natural cellophane, derived directly from cellulose found in plant fibers, offers biodegradable and eco-friendly properties but is rare due to complex extraction processes. Regenerated cellophane, produced by dissolving cellulose and reforming it into thin films, dominates the market because of its consistent quality and versatility in packaging applications. Understanding these differences highlights the balance between sustainable sourcing and manufacturing efficiency in the cellophane industry.

What is Natural Cellophane?

Natural cellophane is a transparent film made directly from cellulose derived from plants such as cotton, wood pulp, or hemp, without chemical regeneration. It retains the original polymer structure of cellulose, ensuring biodegradability and non-toxicity, making it an eco-friendly alternative to synthetic plastics. Unlike regenerated cellophane, which undergoes chemical processing to extract cellulose and reform it into thin films, natural cellophane maintains its innate molecular composition, resulting in distinct physical and chemical properties.

Defining Regenerated Cellophane

Regenerated cellophane is a transparent film produced by chemically treating cellulose derived from wood pulp or cotton fibers, transforming it into a pliable, biodegradable material. Unlike natural cellophane, which is made directly from cellulose-rich plant sources, regenerated cellophane undergoes a process of dissolution and reformation that enhances its uniformity and strength. This refined manufacturing method creates a versatile packaging film used extensively in food wrapping and industrial applications due to its moisture-resistant and breathable properties.

Production Processes: Natural vs Regenerated Cellophane

Natural cellophane is derived directly from cellulose-rich plant sources like wood pulp and cotton through a purely physical process that preserves its raw material's original structure. Regenerated cellophane, however, is produced by chemically dissolving cellulose in solvents before reforming it into thin sheets, allowing for enhanced control over film properties such as transparency and strength. The regeneration process involves additional steps like purification and chemical treatment, resulting in a more uniform and versatile cellophane film compared to natural cellulose films.

Key Material Differences Between Natural and Regenerated Cellophane

Natural cellophane is produced directly from cellulose fibers extracted from plant sources, retaining its original fiber structure with minimal chemical alterations. Regenerated cellophane undergoes extensive chemical processing, where cellulose is dissolved and then re-formed into thin films, resulting in a more uniform and flexible material. Key material differences include natural cellophane's higher purity and lower cost contrasted with regenerated cellophane's enhanced mechanical strength, clarity, and moisture resistance.

Environmental Impact: Comparing Sustainability

Natural cellophane, derived from cellulose found in wood pulp, is biodegradable and compostable, resulting in minimal environmental harm during disposal. Regenerated cellophane undergoes chemical processing involving solvents and plasticizers, which can introduce pollutants and increase energy consumption in manufacturing. Both types offer sustainability advantages over synthetic plastics, but natural cellophane's lower processing footprint and rapid biodegradability make it a more eco-friendly option.

Applications and Uses in Packaging Industry

Natural cellophane, derived primarily from cellulose in wood pulp and cotton, is valued in the packaging industry for its biodegradability and transparency, making it ideal for environmentally friendly food wraps and floral packaging. Regenerated cellophane, produced through the viscose process, offers enhanced strength and moisture resistance, leading to widespread use in packaging for snacks, candies, and other moisture-sensitive products. Both forms support sustainable packaging solutions, but regenerated cellophane's improved durability extends its application to areas requiring longer shelf life and better mechanical protection.

Performance and Durability Comparison

Natural cellophane, derived directly from cellulose, exhibits moderate tensile strength and biodegradability but lacks uniformity in quality and consistency. Regenerated cellophane, produced through chemical processing of cellulose pulp, offers enhanced durability, improved moisture resistance, and greater flexibility, making it more suitable for packaging applications requiring longer shelf life. The chemical modifications in regenerated cellophane significantly boost its performance by increasing tensile strength and resistance to oils and fats compared to natural cellophane.

Cost Analysis: Natural vs Regenerated Cellophane

Natural cellophane, derived directly from cellulose-rich plants, generally incurs higher raw material costs due to limited availability and processing complexity. Regenerated cellophane, produced by chemically dissolving and reforming cellulose, benefits from scalable industrial manufacturing, resulting in lower production expenses and more consistent pricing. Cost analysis reveals that regenerated cellophane offers a more economical choice for mass applications, while natural cellophane remains niche due to its premium sourcing and environmental factors.

Choosing the Right Cellophane for Your Needs

Natural cellophane, derived directly from cellulose in wood pulp or cotton, offers superior biodegradability and a more eco-friendly profile compared to regenerated cellophane, which undergoes chemical processing to achieve similar properties. When choosing the right cellophane for packaging or artistic purposes, consider factors such as environmental impact, transparency, and moisture resistance; natural cellophane excels in sustainability, while regenerated variants may provide enhanced durability and uniformity. Assessing your specific needs in terms of biodegradability, clarity, and strength ensures optimal selection between natural and regenerated cellophane.

Natural Cellophane vs Regenerated Cellophane Infographic

materialdif.com

materialdif.com